Basic Info.

Model NO.

2 in 1

Customized

Customized

Condition

New

Color

Customized

Size

Customized

Control

CNC or PLC

Model

Go

Product Name

Material Feeder

Transport Package

Export Package

Trademark

BOLI

Origin

China

HS Code

84639000

Production Capacity

5000

Product Description

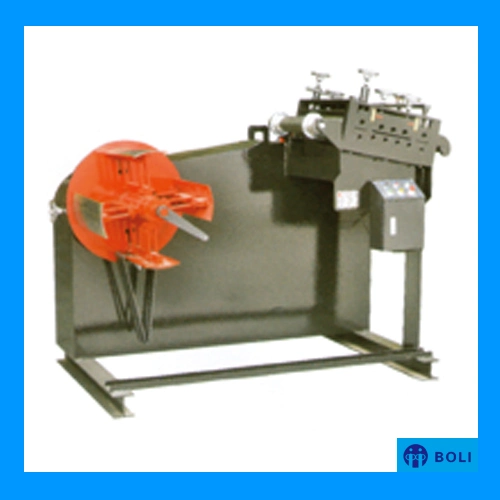

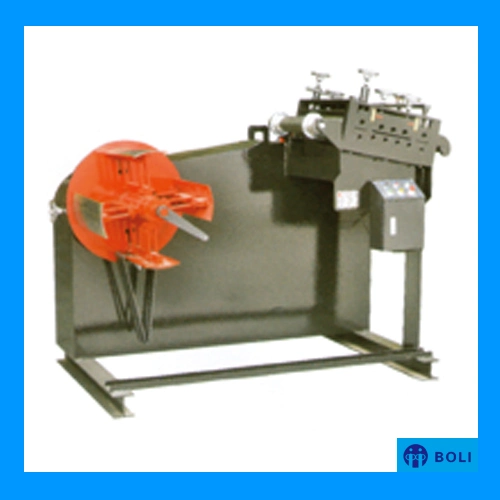

2 IN 1 Uncoiler and Leveler

Features:

> Integrated with uncoiler and straightener, save volume, suitable for board processing. Automatically adjust feeding time to output speed.

> All rolls are made of bearing steel, have all been quenched, hard-chrome plated and grinded with mim HRC60.

> Use Japanese electromagnetic contact and electric parts, long service life.

> A stepless variable speed control is used normal and high speed operation, control by modern frequency converters, keep pace with straightening, stable feeding.

> Leveler in clines appropriately to reduce feeding loop distance.

> Constructed with highly rigid structure and designed with a powerful motorized feeder.

Change feeding speed ( selective):

> Motor can use double-shift control.

> Transducer control wearable and long service life.

Specification:

Features:

> Integrated with uncoiler and straightener, save volume, suitable for board processing. Automatically adjust feeding time to output speed.

> All rolls are made of bearing steel, have all been quenched, hard-chrome plated and grinded with mim HRC60.

> Use Japanese electromagnetic contact and electric parts, long service life.

> A stepless variable speed control is used normal and high speed operation, control by modern frequency converters, keep pace with straightening, stable feeding.

> Leveler in clines appropriately to reduce feeding loop distance.

> Constructed with highly rigid structure and designed with a powerful motorized feeder.

Change feeding speed ( selective):

> Motor can use double-shift control.

> Transducer control wearable and long service life.

Specification:

| model | material width | material thickness | material I.D. | material O.D. | material weight | speed of feed | motor | coil expansion | machine weight | machine (LxWxH) |

| mm | mm | mm | mm | kg | m/min | hp | kg | m | ||

| GO-200 | 200 | 0.4-3.2 | 450-530 | 1200 | 800 | 15 | 1 | manual | 1000 | 2x1.4x1.4 |

| GO-300 | 300 | 0.4-3.2 | 450-530 | 1200 | 1000 | 15 | 2 | manual | 1100 | 2.1x1.5x1.5 |

| GO-400 | 400 | 0.4-3.2 | 450-530 | 1200 | 1200 | 15 | 2 | manual | 1200 | 2.2x1.6x1.6 |

| GO-500 | 500 | 0.4-3.2 | 450-530 | 1200 | 2000 | 15 | 3 | manual | 1400 | 2.3x1.7x1.7 |

| GO-600 | 600 | 0.4-3.2 | 450-530 | 1200 | 2500 | 15 | 3 | manual | 1600 | 2.4x1.8x1.8 |

| GO-700 | 700 | 0.4-3.2 | 450-530 | 1200 | 2500 | 15 | 5 | manual | 1800 | 2.5x1.9x1.9 |