Basic Info.

Model NO.

amd-hb

Power Source

Hydraulic Pressure

Precision

High Precision

Certification

CE, ISO 9001

Condition

New

Warranty

One Year

Industrial Experience

Over 20 Years Professional Experience

After-Sales Service Provided

Available to Service Machinery Overseas

Dimension(L*W*H)

Customized

Application

Sheet Metal Processing

Hole Accuracy

0.5mm

Delivery Time

35 Workdays

Transport Package

Pallet, Foam and Plastic Film/Customized

Specification

CE, Sa 2.5

Trademark

PUHUA

Origin

Shandong China(Mainland)

HS Code

84243000

Production Capacity

200 Sets Per Year

Product Description

Thick Plate Hydraulic CNC Punching Machine For 30mm Sheet Metal

•Using in-line type die set which researched and developed by our company, matching with thick plate stamping dedicated mould, the processing sheet thickness can up to 16mm; •Equipped with high precision hydraulic main transmission system, speed is faster, stroke is adjustable;

•Adopts Siemens CNC special system and match up digital AC servo motor to make it faster and reliable, operation is easy, no need manual programming and processing, with the second positioning function, can achieve no dead zone processing;

•Equipped with concentrated lubricating device, reduce each kinematic pair friction, improve machine service life.

Application:

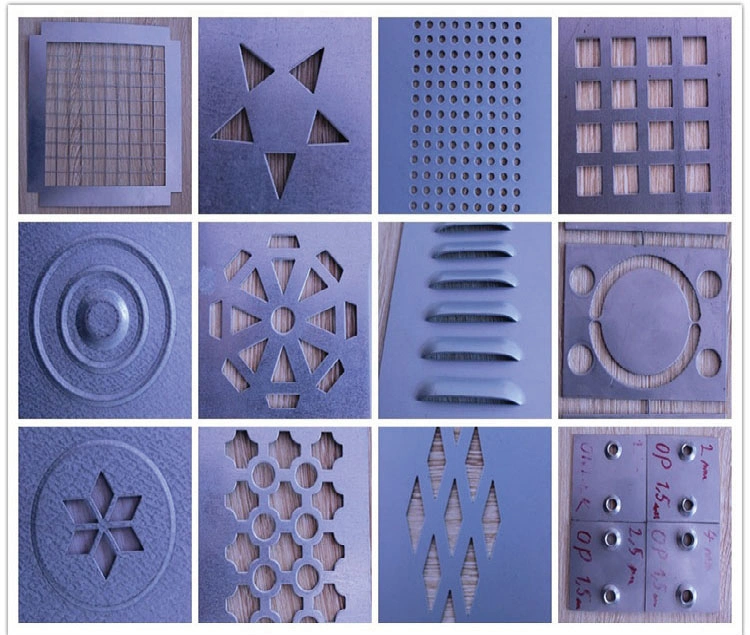

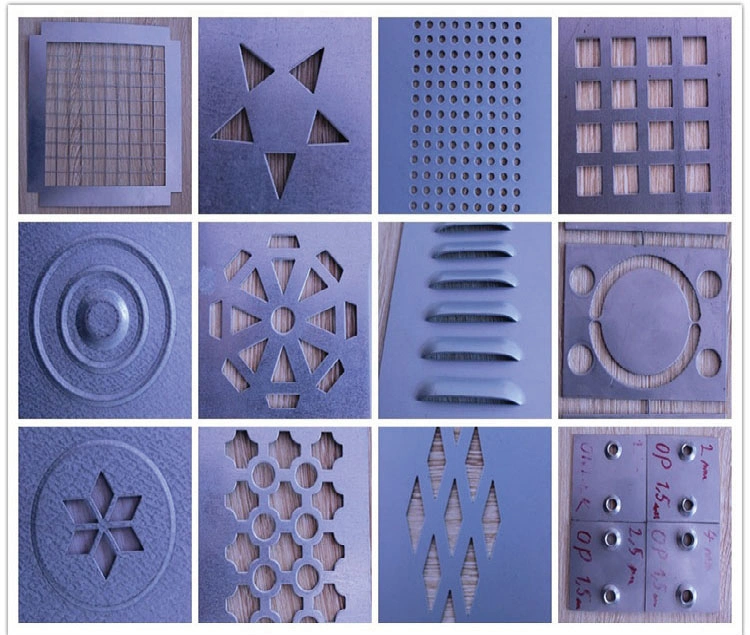

The machines are mainly used for punching holes on the thick steel plate used in cars trabecular, automotive girder, thick plate ventilation holes, steel construction, steel bridge, ship building and those sort of applications.

How much the processable sheet thickness?

6mm? No.

12mm?? No!

20mm? No!!

25mm? YES! Even 25-30mm are no problem.

What's the advantages of this machine?

FAQ:

Warmly Reminder:

According to your requirements, the most suitable machines will be designed for your workpieces, please indicate the following details.

1. What is your metal sheet material?

2. The workpiece size, length, width and thickness.

3. How many hole shapes and hole diameter?

Looking forward to receiving your inquiry of CNC punching machine.

•Using in-line type die set which researched and developed by our company, matching with thick plate stamping dedicated mould, the processing sheet thickness can up to 16mm; •Equipped with high precision hydraulic main transmission system, speed is faster, stroke is adjustable;

•Adopts Siemens CNC special system and match up digital AC servo motor to make it faster and reliable, operation is easy, no need manual programming and processing, with the second positioning function, can achieve no dead zone processing;

•Equipped with concentrated lubricating device, reduce each kinematic pair friction, improve machine service life.

Application:

The machines are mainly used for punching holes on the thick steel plate used in cars trabecular, automotive girder, thick plate ventilation holes, steel construction, steel bridge, ship building and those sort of applications.

How much the processable sheet thickness?

6mm? No.

12mm?? No!

20mm? No!!

25mm? YES! Even 25-30mm are no problem.

What's the advantages of this machine?

| 1 | Reduce investment in fixed assets |

| 2 | Greatly improve production efficiency |

| 3 | High value of waste recycling |

| 4 | Saving labor costs |

| No. | Specification | Parameter |

| 1 | Transmission mode | Hydraulic |

| 2 | Punch Force | 800-3000KN |

| 3 | Power Rating | 20-38 KW |

| 4 | Max. Processing Size | 2500*1250mm |

| 5 | Max. sheet Thickness | ≤25 (carbon steel) |

| 6 | Max. Punch Diameter | Φ150mm |

| 7 | Max. Traversing Speed | 30m/min |

| 8 | Stamping stroke | 100mm |

| 9 | Ram stroke | 35mm |

| 10 | Throat depth | 1275mm |

| 11 | X/Y axis stroke | X=2500mm / Y=1250mm |

| 12 | Punching Frequency | 60hpm |

| 13 | Hole Accuracy | ±0.1mm |

| 14 | Number of stations in turret | 2-12 stations |

| 15 | Max.loading weight | 600kg |

| 16 | Controlled Axis | 2 axis |

| 17 | Air Pressure | ≥0.6mpa |

| 18 | Quantity of clamps | 3 |

| 19 | Clamp construction | All-floating, hydraulic |

| 20 | Reposition device | Yes |

| 21 | CNC system | Siemens |

| 22 | Heat treatment of frame | Annealing |

| 23 | RS232C communication interface | Yes |

| 24 | Machine Weight | About |

FAQ:

| After-sale service | |

| Installation and commissioning issue | We will send one technician to guide machine installation and commissioning, customer pays for his tickets, local transportation, hotel and diet. Customer arrange skilled workers and installation machinery and tools in advance. |

| Warranty time | 12 months from date of commissioning completion, but no more than 18 months from date of delivery. |

| Supply full English documents | Including general installation drawings, pit design drawings, manual book, electric wiring diagram, electric manual book, maintenance book, etc. |

| Exported experience | Since 2009, over 90 countries, including The USA, Germany, Canada, Russia, UK, Australia, Malaysia, UAE, Egypt, Mexico, Brazil, etc. |

| Trade Information | |

| MOQ | 1set |

| Settlement Currency | USD, RMB, EUR. |

| Trade mode | FOB (FCA), CIP, CFR, CIF, DDU, DDP, Turnkey. |

| Payment term | 30% deposit by T/T, the balance paid before delivery or L/C at sight, etc |

| Delivery time | Within 20-60 days according to different type equipment. |

Warmly Reminder:

According to your requirements, the most suitable machines will be designed for your workpieces, please indicate the following details.

1. What is your metal sheet material?

2. The workpiece size, length, width and thickness.

3. How many hole shapes and hole diameter?

Looking forward to receiving your inquiry of CNC punching machine.