Basic Info.

Product Description

THD01 aluminum collapsible tube annealing oven is a supporting equipment for aluminum collapsible tube production line.

The molecular structure of the extruded aluminum tubes generates stress and it lose flexibility. To de-stress it is annealed at a certain temperature, which makes it soft , burn off the dirt and lubricants from the tube to prepare dirt free surface to receive prints.

The annealing oven adopts the form of electric heating, which is safe and clean. Conveying basket chain puts germ tubes into the "C" basket one by one. The tubes are then driven to the oven where they are heated for 3-5minutes. After that, the tubes are sent to the cooling section and then to the next procedure.

Main Features

A. The electric heating components adopt stainless steel thermal resistance and have features of uniform heating and easy operation. Heating components are easy to detach and replace.

B. FUJI temperature controller ensures the temperature within plus or minus 2 ºC of setting temperature.

D. The oven chamber adopts suspended structure which is convenient for maintenance and makes the conveying basket more stable during the operation of the furnace cavity, reducing the incidents of dropping and crushing tubes, so as to improve the qualified rate of products.

F. The machine is equipped with a single driving motor. It can operate synchronously with the equipment before and after, or operate separately.

Main technical parameters

| 1. Production speed | ≤ 60 tubes/min |

| 2. Tube diameter range | φ13.5-22-φ25-35mm |

| 3. Tube length range | ≤ 200 mm |

| 4. Power | 32 kw |

| 5. Upper shafts | 2 axis |

| 6. Dimensions | 4900*1300*3100 mm |

| 7. Weight | 1800 KG |

| 8. Working temperature | 200-500 ºC |

| 9. Heating time | 50 min |

| 10. Annealing time | 2.5 min |

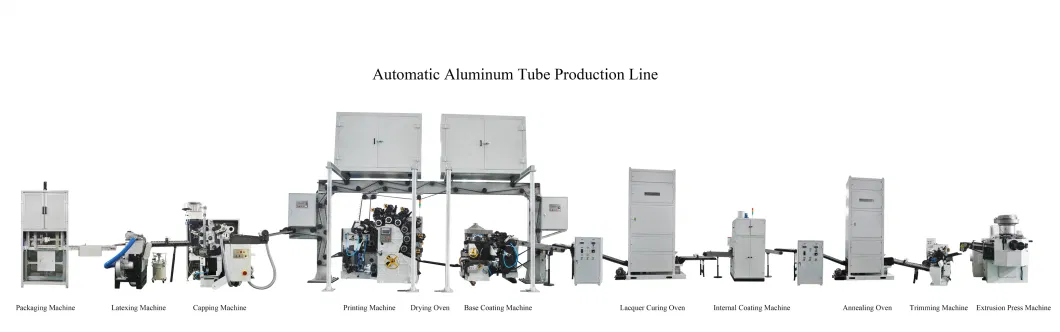

Machine appearance

Packing & Delivery

Company Profile

Wuxi Yingrun Machinery Technology Co., Ltd. is located in beautiful Wuxi, China, only 150 kilometres away from Shanghai.

The company is mainly engaged in the production, sales, consulting and service of aluminum tube production line, aerosol can production line and toothpaste production line. We have more than 20 years of experience. Our products have passed the EU CE certification. Providing customers with better products and services is always our code of conduct. We also provide professional consulting and technical support to our clients.

FAQ

Q: What's the MOQ?

A: 1 set.

Q: Are you trading company or manufacturer?

A: Both. We have our own factory to produce machines and also as the agents of some materials, such as parts, slug, latex...

Q: How long is your delivery time?

A: 1-10 months by negotiation.

Q: What's the warranty time?

A: One year start from installed.

Q: How to use?

A: We offer paid installation, commissioning and training.

Q: Can I visit your factory?

A: You're welcomed any time.