- Overview

- Products Description

- PRODUCT SPECIFICATIONS

- PRODUCT CONFIGURATION

- Exportation market percentage

- Our Advantages

- Makeable product

- Other hot selling product

- FAQ

Basic Info.

Model NO.

5-10

Certification

CCC, ISO9001

Warranty

12 Months

Customized

Customized

Condition

New

Weight (Kg)

800

Warranty of Core Components

Not Available

Servo Cutting Motor

1kw

Length Error

+-0.5mm (After Per 500mm)

Key Selling Points

Automatic

Extra Services

Cutting/Intelligent Control

Machinery Test Report

Provided

Machine Type

Wire Cutting Machine

Feeding Speed

7-30 M /Min

Feeding Motor Power

3.7 Kw with Reducer Gh40

Raw Material

Steel Bar

Core Components

PLC, Engine, Gearbox, Motor, Gear

Material / Metal Processed

Stainless Steel/Copper/Aluminium

Wire Diameter

5-9 mm Iron Wire

Cutting Length Range

More Than 50 mm

Transport Package

Wooden Large Box with Screw

Specification

iron frame

Trademark

JC

Origin

Guangdong, China

HS Code

8463300000

Production Capacity

200 Set/Sets Per Month

Product Description

5-9mm Servo wire straighten and cutting machine with intelligent system for stainless steel, low carbon wire and other material

The range of wire diameter which can be cut is very wide. 2---12 mm diameter steel wire can be chosen to cut. The cross section can be cut 50 mm at least. It can cut and straighten many kinds of material such as iron, low carbon steel, stainless steel, copper, Aluminium etc other metals. The error is only 0.5 mm so please don't suspect its ability.By the way, the speed could be 40 m/min. It is same as about 2-3 sets yield of outdated straighten machine. The most important is its stability and flexible operation. There is no any over bending and loss of material. Every steps can be controlled by computer.

| Type | Information& Data | Type | Information&Data |

| Wire diameter | 5-9 mm | Cutting motor | 1 kw(3000r) Servo cutting |

| Cutting length range | more than 50MM | Cutting oil cylinder model | MOB80-20 |

| Feeding speed | 7-30m/min | Wire diameter range | 4-9mm low carbon steel (4-7mm stainless steel) |

| Length error | +-0.5mm | Machine size | 3070*900*1450 mm |

| Feeding motor | 3.7kw with reducer | Wire shelve | Normal shelve without any power |

| Straighten motor | 7.5kw---2P | Option | Automatic shelve can be rotated automaticlly |

| Cutting servo motor | 1kw 1500r | | |

| Feeding group | 2 groups | | |

| Screen | Touch screen | | |

| Straighten component quantity | 6pcs | | |

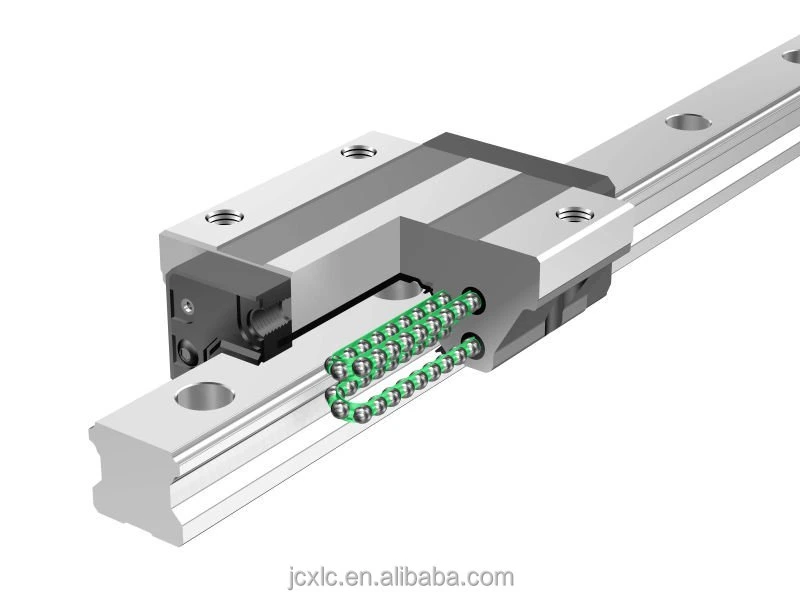

PLC made from ARCUCH Imported Oriental planet moto Linear from Taiwan HIWIN Oriental planet

JC automatical machine can export all over the world and main market is middle-east, Southeast Asia and Eastern Europe market. Welcome contact us to ask more details.

Automation

It takes PLC system and comes with English instruction. Feeding, straightening, cutting and coiling operation are automation

Automatic shutdown

It comes with the protection function of automation shutdown when the wire be cut in accident.

Servo motor cutting

The blocking of material will not happen by the servo motor machine

Consultation function

The data could be modified,deleted or added by this function

Memory function

The computer can deposit several data such as length and quantity

Intelligent modification

The AI supply hint for modification and check if it is acceptable.

Stainless steel

Aluminium

Copper

Sliver

Low carbon steel

Black iron wire

3D wire bending machine

Servo Straighten and cutting machine

2D CNC wire bending machine

Q1. Why choose us?

A. Our founding team has more than 20 years of experience in the R&D and manufacturing industry of metal forming and welding machinery. What we offer is a good product at a reasonably price.

Q2. Can I customize the product?

A. Yes . We can customize production equipment solutions according to your product requirements .

Q3. Can I get a sample?

A. Yes. But the proofing cost and shipping are negotiated by both parties.

Q4. What's the delivery time?

A. The delivery time needs to be determined by both parties through negotiation .

Q5. How do I order from you?

A. Consulting → equipment plan quotation →negotiation→ prototyping →PO/PI→ payment deposit → production → debugging →

delivery→further.

If you want more product information, please feel free to contact us!

A. Our founding team has more than 20 years of experience in the R&D and manufacturing industry of metal forming and welding machinery. What we offer is a good product at a reasonably price.

Q2. Can I customize the product?

A. Yes . We can customize production equipment solutions according to your product requirements .

Q3. Can I get a sample?

A. Yes. But the proofing cost and shipping are negotiated by both parties.

Q4. What's the delivery time?

A. The delivery time needs to be determined by both parties through negotiation .

Q5. How do I order from you?

A. Consulting → equipment plan quotation →negotiation→ prototyping →PO/PI→ payment deposit → production → debugging →

delivery→further.

If you want more product information, please feel free to contact us!