Basic Info.

Model NO.

SSC1860

Touch Screen

Siemens

Low-Voltage Electrical Parts

Specified by Customer

Bearing

NSK

Painting

Customzied

Transport Package

Wooden Cases

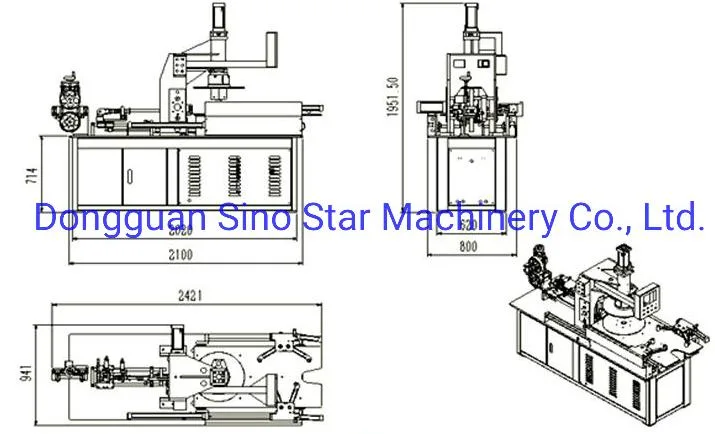

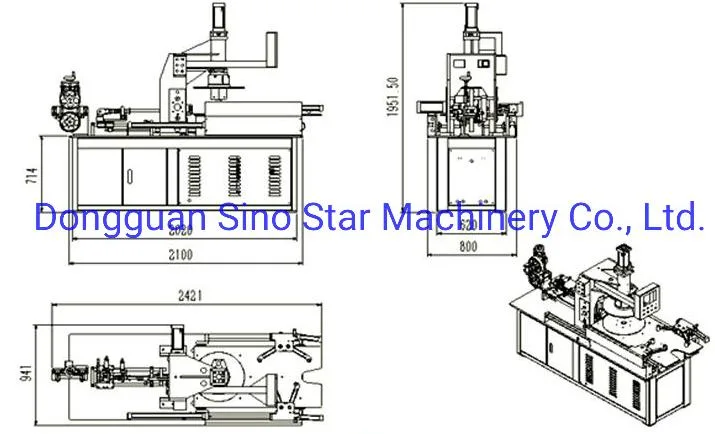

Specification

L2421*W941*H1951

Trademark

SINO STAR

Origin

Dongguan, China.

HS Code

8425319000

Production Capacity

260 Sets/Year

Product Description

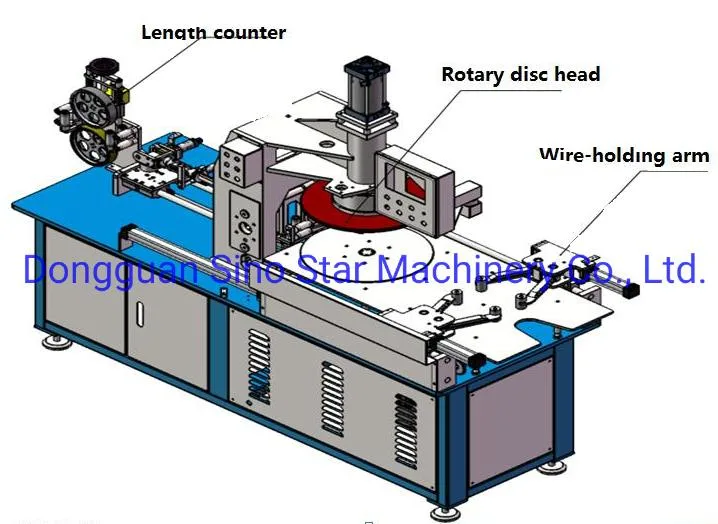

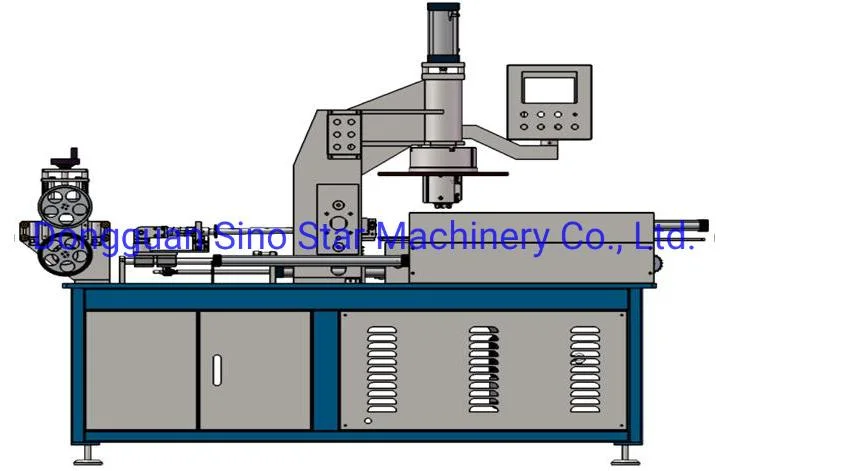

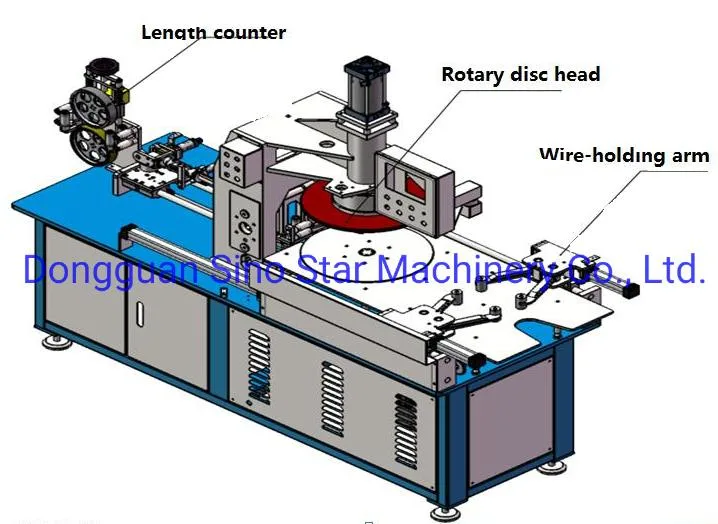

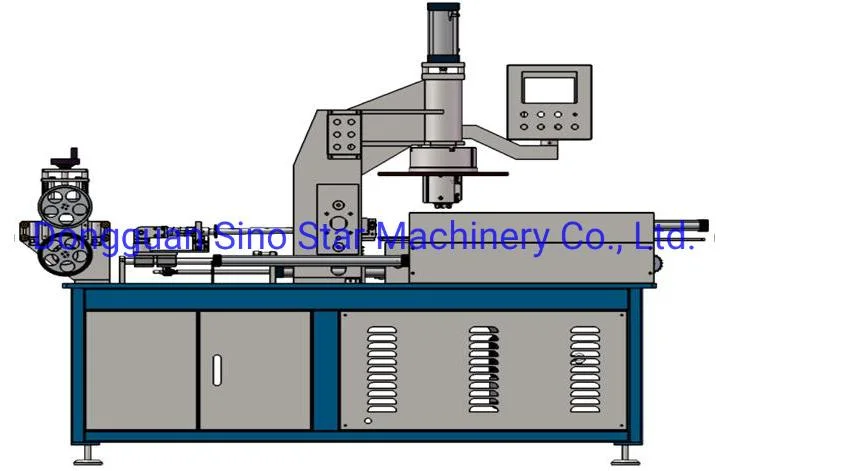

Automatic Wire Cable Coiling Coil Rolling Winding Packing Making Machine for Automobile Flexible Wires

Computerized automatic coiling machine/coiler

Application: it is mainly used to take up and coil electronic cables, , computer cables, automobile flexible wires, BV/AV power cable and building wires.

Main features:

Our main models are as follows

Detailed description of the mechanical composition of this machine

1. Meter-counting part: upper/lower wheel each one, using precise encoder to calculate wire

length and its precision can be up to centimeter. Meter-counting wheel is made of aluminum

alloy material. The lower wheel will be coated with good-quality glue. the upper wheel will be

coated with ceramics and hardened to make sure they won't hurt wires and have been equipped

with unidirectional bearing in order to prevent the cables from wincing.

2. Rotary circular disk head: horizontal coiling, it is controlled to be open and closed

automatically by air-pressure propeller. When the pre-set length of wire is coiled it will stop

coiling automatically, at this moment the rotary head will be vertically internal contraction to

raise, which won't clamp wires and contact coils, easy ejection from the mould. The

specification of rotary circular disk head is fixed, customer should let us know the detailed

requirement, if customer wants to change the internal diameter of wire roll customer has to

purchase another one with the size customer needs.

3. Traversing system: completely and automatically controlled by micro-computerized system,

Adopting 400W servo motor to drive leading screw and receiving running signal of driven

motor via precise encoder to make the servo motor run synchronously with the driven motor

and make the action of wire more coordinative and the cable rolls more beautiful.

4. Cutter: Portal cutter, when the length of the coil reaches the pre-set length, it will cut wire

automatically. Pneumatic double cutter is made of SKD-11 special steel and experienced

vacuum heat treatment, which will make its hardness more higher and service life longer.

5. Servo wire-holding system:

After the wire coiling is finished, wire-holding structure will hold wire roll and automatically

send it to the packing platform.

6. Operation panel:

Man-machine interface operation system, contact screen to operate, it is very easy. Central

computer control system can control coiling speed, coil length, alarm system, line speed

regulation, pilot lamp, emergency stop and re-set etc function. Wire length, wire diameter and

line speed data etc can be modified in the course of machine running without stopping the

machine, Line speed, wire length and the status of the complete machine can be seen on the

screen. Micro-computerized memory can store 99 different kinds of wire roll.

The photos of our NEW TYPE automatic coiler/coiling machine/winding machine/rolling machine made by SINO STAR are listed out below for your reference.

PACKAGE AND SHIPPING:

Nomally we use wooden cases or PFfilm to pack our machines as required to guarantee that our machines won't been damaged in the course of long-disance sea transportation.

Our Service

Pre-sales service including:

- Analyse customer's inquiry and reply to customer within 12 hours after receiving the inquiry from customer.

- Communicate with customer and help customer to choose the well-suitable machines for customer.

- Sending drawings to customer for confirmation to make all is clear before placing order with us.

- Prepare the final proposal for customers

- Invite customer to visit our factory or we can visit our customer's factory to held a face-to-face meeting if possible

After-Sales Service

- Training customer's workers how to install, operate and maintain our machines

- Engineers available to provide overseas maintenance service for all our machines working abroad.

Customers Q&A:

A1: Are you the manufacturer or trading company ?

Q1: We are the factory with 3 big workshops covering 6000 s.q.m; Warmly welcome you to visit our factory and conduct our work.

A2: What's your factory's advantage over other manufacturers in the same industry ?

Q2 - High output capacity will guarantee your high-efficient production

- We are very good at engineering; In order to make our machine have a very excellent performance; we are rigorously attaching importance to each detail in the course of manufacturing in a bid to improve our machines continuously.

- We only mount electrical components under famous brands like Siemens,Yaskawa, Scheinder

and Omron on our machines to guarantee the quality of our machines.

- Our engineers and workers can work abroad; if you need us to assist you installing and testing

the machines or training your staff how to operate and maintain our machines; we can send our team to your factory when our machines arrive at your factory.

- Guarantee period: We can guarantee two years for all our machines

- After-sales service: We promise to provide permanent technical support and after-sales service with our customers.

A3: Why do we trust your company ?

Q3: We have been engaging into cable machinery industry for over 30 years and have agent in Europe since 2007. Up to now we have exported our machines to many countries.

A4: Where is your factory ? How can we visit you ?

Q4: Our factory is located in Dongguan, Guangdong Province, China, very close to Shenzhen and Guangzhou. You can pick you up at Humen railway station (you can take high-speed train from Guangzhou South Railway sation or Shenzhen North station, it takes you only 10 minutes by high speed train to reach Humen Railway station)

We are sincere to long for working together with customers from all around the world. Warmly invite you visit our fatory DONGGUAN SINO STAR MACHINERY CO.,LTD at your convenient time !

Computerized automatic coiling machine/coiler

Application: it is mainly used to take up and coil electronic cables, , computer cables, automobile flexible wires, BV/AV power cable and building wires.

Main features:

- Automatically coil wire from extrusion line or the payoff

- Touch screen operation, servo motor traversing system, automatic detecting error.

- It can save 99 different specifications of coil in the PLC memory. No need to adjust the machine when changing coil specification.

- Automatic nonstop production, conveyor automatically changes over take-up coils.

- Traversing and traversing density can be adjustable. Takeup capacity is very big

- Highspeed payoff without fault.

- Three phase AC motor drive without needing to maintain

- Dynamic balance with highgrade precision, stable running at high speed.

Our main models are as follows

| Model | Height(mm) | O.D. (mm) | I.D. (mm) | Cable Dia. (mm) | Max.rotary speed (RPM) |

| SSC1246 | 50~120 | 200~460 | 140~220 | 1~12 | 930 |

| SSC1860 | 60~200 | 220~600 | 180~250 | 5~15 | 500 |

| SSC2480 | 80~240 | 300~800 | 250~320 | 10~25 | 100 |

Detailed description of the mechanical composition of this machine

1. Meter-counting part: upper/lower wheel each one, using precise encoder to calculate wire

length and its precision can be up to centimeter. Meter-counting wheel is made of aluminum

alloy material. The lower wheel will be coated with good-quality glue. the upper wheel will be

coated with ceramics and hardened to make sure they won't hurt wires and have been equipped

with unidirectional bearing in order to prevent the cables from wincing.

2. Rotary circular disk head: horizontal coiling, it is controlled to be open and closed

automatically by air-pressure propeller. When the pre-set length of wire is coiled it will stop

coiling automatically, at this moment the rotary head will be vertically internal contraction to

raise, which won't clamp wires and contact coils, easy ejection from the mould. The

specification of rotary circular disk head is fixed, customer should let us know the detailed

requirement, if customer wants to change the internal diameter of wire roll customer has to

purchase another one with the size customer needs.

3. Traversing system: completely and automatically controlled by micro-computerized system,

Adopting 400W servo motor to drive leading screw and receiving running signal of driven

motor via precise encoder to make the servo motor run synchronously with the driven motor

and make the action of wire more coordinative and the cable rolls more beautiful.

4. Cutter: Portal cutter, when the length of the coil reaches the pre-set length, it will cut wire

automatically. Pneumatic double cutter is made of SKD-11 special steel and experienced

vacuum heat treatment, which will make its hardness more higher and service life longer.

5. Servo wire-holding system:

After the wire coiling is finished, wire-holding structure will hold wire roll and automatically

send it to the packing platform.

6. Operation panel:

Man-machine interface operation system, contact screen to operate, it is very easy. Central

computer control system can control coiling speed, coil length, alarm system, line speed

regulation, pilot lamp, emergency stop and re-set etc function. Wire length, wire diameter and

line speed data etc can be modified in the course of machine running without stopping the

machine, Line speed, wire length and the status of the complete machine can be seen on the

screen. Micro-computerized memory can store 99 different kinds of wire roll.

The photos of our NEW TYPE automatic coiler/coiling machine/winding machine/rolling machine made by SINO STAR are listed out below for your reference.

PACKAGE AND SHIPPING:

Nomally we use wooden cases or PFfilm to pack our machines as required to guarantee that our machines won't been damaged in the course of long-disance sea transportation.

Our Service

Pre-sales service including:

- Analyse customer's inquiry and reply to customer within 12 hours after receiving the inquiry from customer.

- Communicate with customer and help customer to choose the well-suitable machines for customer.

- Sending drawings to customer for confirmation to make all is clear before placing order with us.

- Prepare the final proposal for customers

- Invite customer to visit our factory or we can visit our customer's factory to held a face-to-face meeting if possible

After-Sales Service

- Training customer's workers how to install, operate and maintain our machines

- Engineers available to provide overseas maintenance service for all our machines working abroad.

Customers Q&A:

A1: Are you the manufacturer or trading company ?

Q1: We are the factory with 3 big workshops covering 6000 s.q.m; Warmly welcome you to visit our factory and conduct our work.

A2: What's your factory's advantage over other manufacturers in the same industry ?

Q2 - High output capacity will guarantee your high-efficient production

- We are very good at engineering; In order to make our machine have a very excellent performance; we are rigorously attaching importance to each detail in the course of manufacturing in a bid to improve our machines continuously.

- We only mount electrical components under famous brands like Siemens,Yaskawa, Scheinder

and Omron on our machines to guarantee the quality of our machines.

- Our engineers and workers can work abroad; if you need us to assist you installing and testing

the machines or training your staff how to operate and maintain our machines; we can send our team to your factory when our machines arrive at your factory.

- Guarantee period: We can guarantee two years for all our machines

- After-sales service: We promise to provide permanent technical support and after-sales service with our customers.

A3: Why do we trust your company ?

Q3: We have been engaging into cable machinery industry for over 30 years and have agent in Europe since 2007. Up to now we have exported our machines to many countries.

A4: Where is your factory ? How can we visit you ?

Q4: Our factory is located in Dongguan, Guangdong Province, China, very close to Shenzhen and Guangzhou. You can pick you up at Humen railway station (you can take high-speed train from Guangzhou South Railway sation or Shenzhen North station, it takes you only 10 minutes by high speed train to reach Humen Railway station)

We are sincere to long for working together with customers from all around the world. Warmly invite you visit our fatory DONGGUAN SINO STAR MACHINERY CO.,LTD at your convenient time !