Basic Info.

Model NO.

qg

Automation

Automatic

Certification

CE, CB, ETL, RoHS, UR

Feature

Rust / Corrosion Proof

Condition

New

Customized

Customized

Saving Energy

Proper Deisgn

After-Sales Service Provided

Engineers Available to Service Machinery Overseas

Shot Blasting Machine Condition

New

Brand Name

Puhua

Shot Blasting Machine Model

Outer Wall Shot Blasting Machine

Exporting Experience

Since 2009, Across The Five Continents

Cleaning Material

Steel Pipe,Tube, Steel Structure

Shot Blasting Machine Use

Metal Rust Removing

Industrial Experience

Over 20 Years Professional Experience

Shot Blasting Machine Warranty

One Year

Transport Package

Stretched Film or Nylon

Specification

CE, Sa 2.5

Trademark

PUHUA

Origin

Shandong Province, China

HS Code

8424300000

Production Capacity

50 Sets/Month

Product Description

Product Description:

QG series steel pipe inner and outer wall shot blasting machine for surface treatment , wiping up the oxide coating , welding slag , appearing the metallic sheen , increasing the area of the surface , which is in favor of UV. It applies in the line of petroleum & chemical , steel , city centralized heating , centralized drainage etc.

Applications of our shot blasting machine: (shot blasting machine)

Descaling of forged or heat treated parts

Desanding of ferrous and non-ferrous metal castings

Deburring of metallic and non-metallic parts

Deflashing of die cast parts

Contaminant removal

Product Parameter:

| Type | Cleaning size(mm) | Cleaning speed(m/min) | Purposes |

| QGW100 | φ50-300 | 2-10 | Outer wall of shot blasting machine |

| QGW720 | φ159-720 | 2-6 | Outer wall of shot blasting machine |

| QGW1200 | φ219-1016 | 1-6 | Outer wall of shot blasting machine |

| QGW1500 | φ325-1600 | 1-6 | Outer wall of shot blasting machine |

| QGW2800 | φ1016-2800 | 1-2 | Outer wall of shot blasting machine |

| QGN100 | φ50-300 | 1-4 | lnner wall of shot blasting machine |

| QGN700 | φ325-720 | 1-2 | lnner wall of shot blasting machine |

| QGN1000 | φ720-1016 | 1-4 | lnner wall of shot blasting machine |

| QGN1500 | φ1016-1500 | 1-4 | lnner wall of shot blasting machine |

Product Details:

Customizable

Various non-standard steel pretreatment equipment can be designed and manufactured according to the steel size you provide.

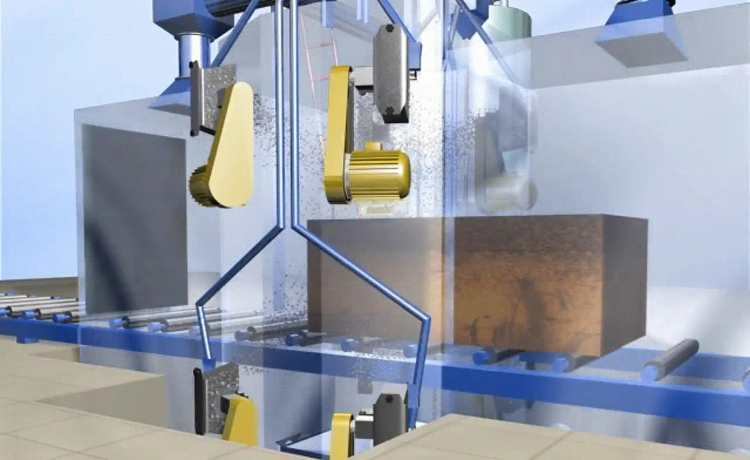

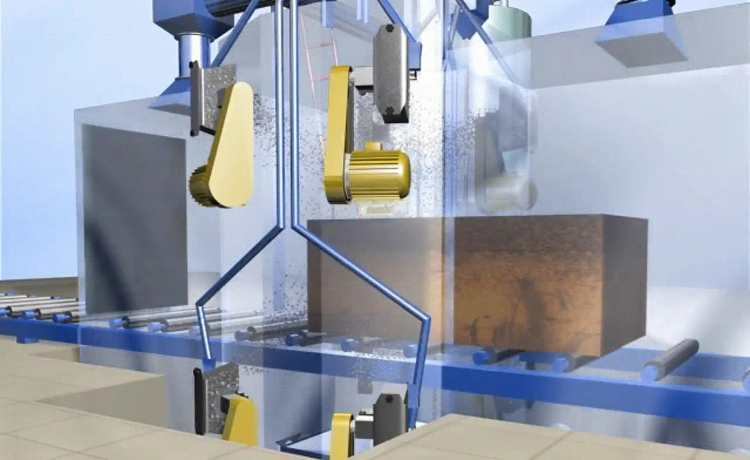

Conveyor system

Long service life

manual or automatic control

Rollers in the blasting cabinet are protected by special alloy jacket with lifetime over 4,000 hours.

Conveyor system is driven by motors with inverter. Rollers can be controlled manually and automatically.

Conveyor system

Long service life

manual or automatic control

Rollers in the blasting cabinet are protected by special alloy jacket with lifetime over 4,000 hours.

Conveyor system is driven by motors with inverter. Rollers can be controlled manually and automatically.

Blasting chamber

high wear resistant performance easy to replace

In the blasting chamber, the wall is protected by SPMn13 material liner and 65Mn protective liner, easy tear open outfit replacement.

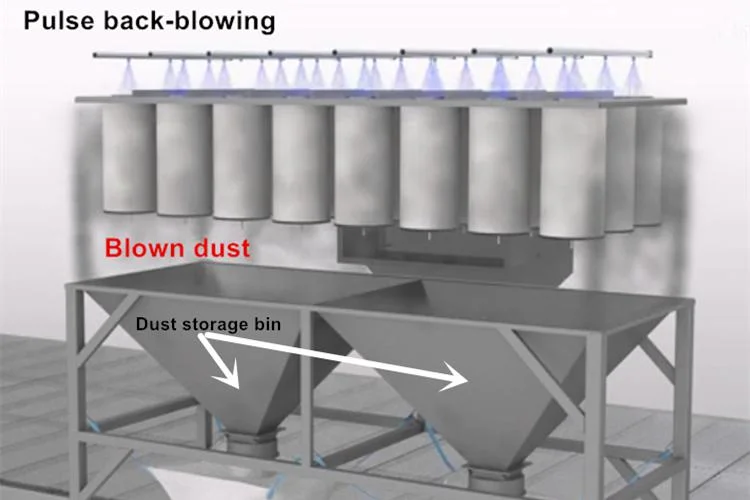

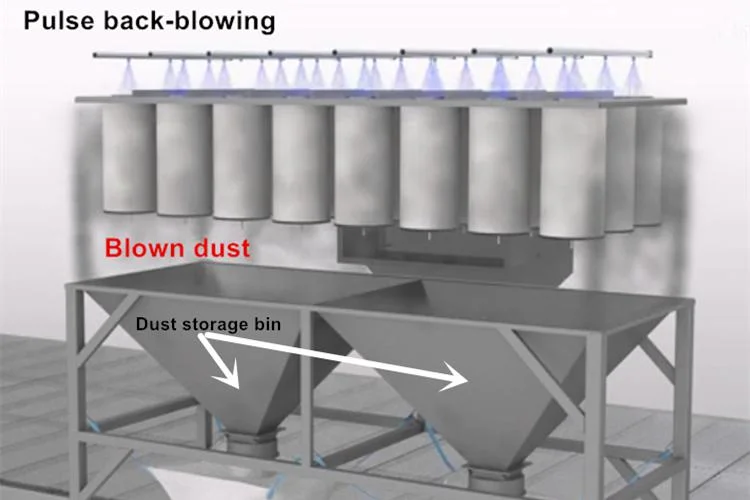

Dust removal system

High dust removal effect

low pollution

The dust removal system consists of ducting system and filter cartridge dust collector. The emission standard can be lower 80 g/m3. The fan power is 30 kw, ventilation quantity is 26000 m3/h.

high wear resistant performance easy to replace

In the blasting chamber, the wall is protected by SPMn13 material liner and 65Mn protective liner, easy tear open outfit replacement.

Dust removal system

High dust removal effect

low pollution

The dust removal system consists of ducting system and filter cartridge dust collector. The emission standard can be lower 80 g/m3. The fan power is 30 kw, ventilation quantity is 26000 m3/h.

Our shot blasting machine's advantages: (shot blasting machine)

1. The machine uses cantilever centrifugal blast wheel, has a long life, simple structure and other characteristics.

2. By full curtain winnowing abrasive mixture separator, with good separation effects and higher productivity, has a positive effect to improve the life of the blasting blade.

3. Use wear-resistant rubber track, decreasing workpiece collision damage phenomenon and then reduce the noise of the machine.

4. Use pulse dust collector, dust can be collected in the dust hopper or exclude to outdoors, improve the labor environment.

What does the shot blasting play role in the working? (shot blasting machine)

Shot blasting machines will eject abrasive media /steel shots to the metal surface of the workpieces under the force of air pressure. After blasting, the metal surface will appear a uniform luster, which will enhance painting dressing quality.

Shot Blasting Machine is named Sand Blasting Machine, Sandblasting, Sandblaster, Cleaning Equipment, Sand Blasting, Sandblasting Machine, Sandblast Machine, Sand Blaster, Industrial Sandblaster, Shot Peening Machine, Shot Blast Cleaning Machine, Shot-Blasting, Abrator and soon on .

Eertified Product:

Our shot blasting machine service:(shot blasting machine)

| 1 | Reply your inquiry in 24 hours. |

| 2 | Experienced staffs answer all your questions in time. |

| 3 | Customized design is available. |

| 4 | Exclusive and unique solution can be provided to our customer by our professional engineers and staff. |

| 5 | Special discount and protection of sales are provided to our distributor. |

| 6 | We are professional manufacturer of shot blasting Machine. Have a professional design team with more than 10 years design experience engineers, competitive with good quality |

| 7 | As an honest seller, we always use superior raw material, advanced machines, skilled technicians to ensure our products to be finished in high quality and stable feature. |

| 8 | Prompt delivery, site installation and commissioning. |

Our shot blasting machine team advantages:

| 1 | 20 years professional production experience in shot blasting machinery industry. |

| 2 | 50,000 m^2 production workshop, strong production capacity. |

| 3 | Professional senior engineer develop the best solution. |

| 4 | Strict quality control system, CE, BV, ISO9001 certificate available. |

| 5 | Main components adopt imported international famous brand. |

| 6 | Timely delivery, one hour to Qingdao port. |

| 7 | Professional after-sale service, Email will be reply in 24 hours. |

| 8 | Site installation and commissioning in your factory. |

Our Company:

FAQ:

FAQ | After-sale service | |

| Installation and commissioning issue | We will send one technician to assist with machine installation and commissioning, customer pays for return tickets, local hotel and diet. Customer should arrange skilled workers and installation machinery and tools in advance. | |

| Warranty time | 12 months from date of commissioning completion, but no more than 18 months from date of delivery. | |

| Supply full English documents | Including general installation drawings, pit design drawings, manual book, electric wiring diagram, electric manual book and maintenance book, etc. | |

| Exported experience | Since 2009, over 90 countries, including The USA, Germany, Canada, Russia, UK, Australia, Malaysia, UAE, Egypt, Mexico, Brazil, etc. | |

| Material of wear parts | Cr20S High Chrome, ZGMn13, Mn65, etc. | |

| Trade Information | ||

| MOQ | 1set | |

| Settlement Currency | USD, RMB, EUR. | |

| Trade mode | FOB (FCA), CIP, CFR, CIF, DDU, DDP, Turnkey. | |

| Payment term | 30% deposit by T/T, the balance paid before delivery or L/C at sight, etc | |

| Delivery time | Within 20-60 days according to different type equipment. | |

Welcome to visit our factory!