- Overview

- Detailed Photos

Basic Info.

Model NO.

RB-805-3

Type

Heat-Resistant Material

Usage

Factory

Fuel

Electric

Feature

Long Time Materials

Shape

Heat-Treatment Line

Material

Mullite

Length of Furnace Line M/M

31995

Transport Package

Seaworthy

Trademark

Rainbow

Origin

China

Production Capacity

100kgs/Hr---2500kgs/Hr

Packaging & Delivery

Package Size

3500.00cm * 1500.00cm * 2500.00cm

Package Gross Weight

50000.000kg

Product Description

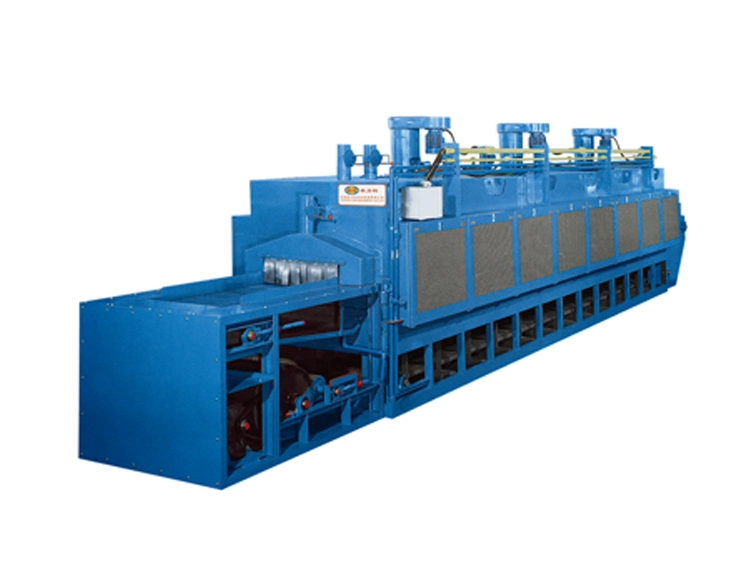

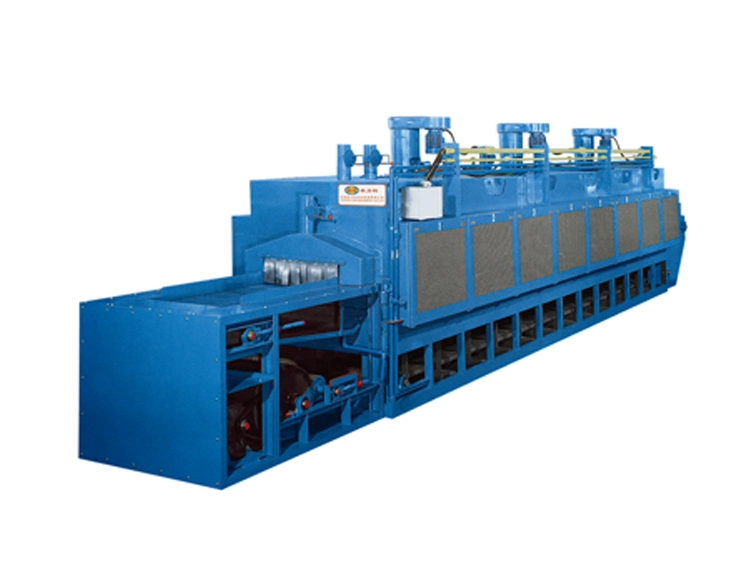

Hardening medium: Oil quenching

Products: Standard fasteners

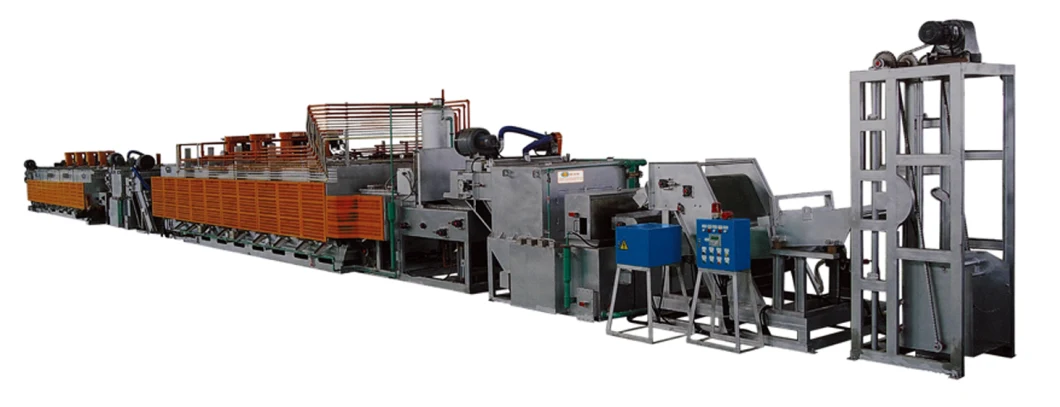

The whole set heat treatment line is composed of Lifting Feeding Machine, Weighting Device, Pre-Water Immersion Type Washer, Vibration Spreader, No-Muffle Carrier Roller Wire-Mesh Belt Controlled Atmosphere Hardening Furnace, Oil-quenching tank, Horizontal type Washer, Wire- mesh belt tempering furnace, Cooling Tank, Electric Control Cabinet, etc.

This kind of heat treatment assembly line adopts Japan foreign furnace technology and is manufactured and inspected according to the standard of resistance furnace industry. Main components adopt imported products and the quality of manufacturing and assembling has reached to the advanced domestic level.

This kind of heat treatment line is a full automatic production line composed of the techniques such as material loading, pre-washing, material distributing, hardening, cooling, post-washing, te

Main furnace's heating adopts low voltage, high current transformer, which lengthens the service life of radiant tube and makes it convenient for maintenance and renewal.

The wire mesh belt adopts synchronous rotating roller, which makes belt endure the lowest tension during operation in order the lengthen the service life.

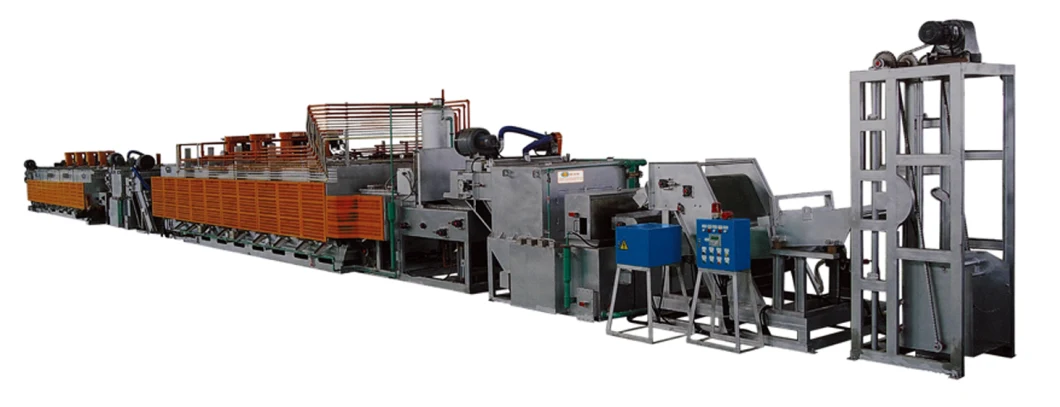

Products: Standard fasteners

The whole set heat treatment line is composed of Lifting Feeding Machine, Weighting Device, Pre-Water Immersion Type Washer, Vibration Spreader, No-Muffle Carrier Roller Wire-Mesh Belt Controlled Atmosphere Hardening Furnace, Oil-quenching tank, Horizontal type Washer, Wire- mesh belt tempering furnace, Cooling Tank, Electric Control Cabinet, etc.

This kind of heat treatment assembly line adopts Japan foreign furnace technology and is manufactured and inspected according to the standard of resistance furnace industry. Main components adopt imported products and the quality of manufacturing and assembling has reached to the advanced domestic level.

This kind of heat treatment line is a full automatic production line composed of the techniques such as material loading, pre-washing, material distributing, hardening, cooling, post-washing, te

mpering and cooling.

Main furnace's heating adopts low voltage, high current transformer, which lengthens the service life of radiant tube and makes it convenient for maintenance and renewal.

The wire mesh belt adopts synchronous rotating roller, which makes belt endure the lowest tension during operation in order the lengthen the service life.

| Model | Power(kw) | Total power(kw) | Working Temp. | Working Dimension(mm) | length ofWorking Area(mm) | Capacity(kgs/h) |

| RB805-A | 80 | 160-180 | 950 | 400*3200*80 | 23000 | hardening 150, carburizing 60 |

| RB805-1 | 120 | 220-250 | 950 | 500*4700*80 | 25000 | hardening 300, carburizing 150 |

| RB805-2 | 220 | 400 | 950 | 600*6000*80 | 38000 | hardening 450, carburizing 220 |

| RB805-3 | 240 | 450 | 950 | 800*6000*80 | 38000 | hardening 150, carburizing 60 |

| RB805-4 | 300 | 480 | 950 | 1000*6000*80 | 37000 | hardening 700, carburizing350 |

| RB805-5 | 460 | 800 | 950 | 1000*10000*80 | 51000 | hardening 1300, carburizing 7500 |

| RB805-6 | 950 | 1800 | 950 | 1200*13500*80 | 60000 | hardening 2500, carburizing 1350 |