- Overview

- Product Description

- Features

- Product Parameters

Basic Info.

Model NO.

PMW3850

Automation

Automatic

Certification

CE, CB, ETL, RoHS, UR

Feature

Rust / Corrosion Proof

Condition

New

Customized

Customized

Impeller Head Power

30kw/Set

Derusting Cost

20-40RMB/T

Production Efficiency

3-8coils Per Hour

Wire Loss

0.2-0.3%

Update Version

Pmw 5500

Production Cycle

One Month

Transport Package

Nuded Cargo

Specification

9.5*6.1*6.9m

Trademark

pumingwei

Origin

China

Production Capacity

500 Sets Per Years

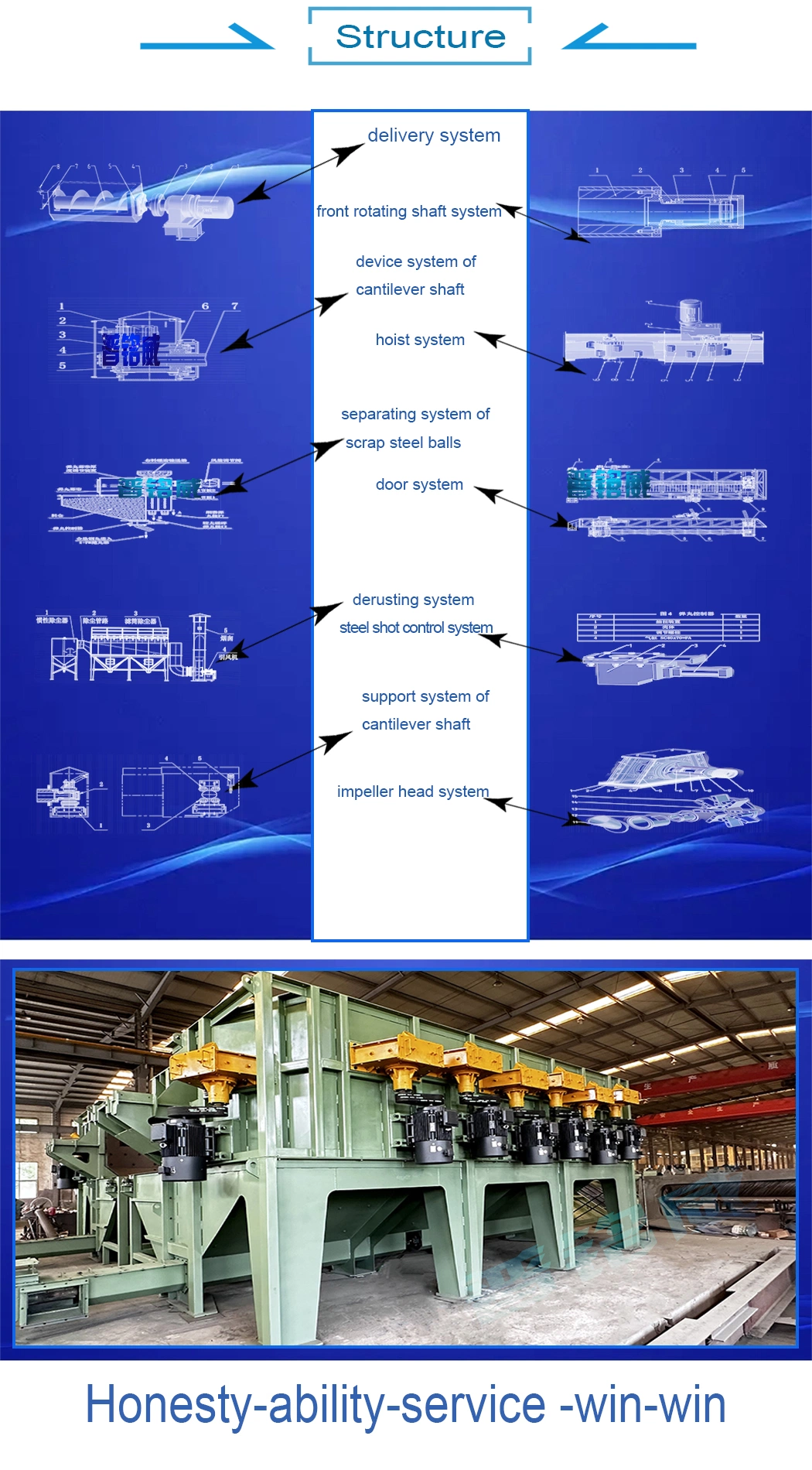

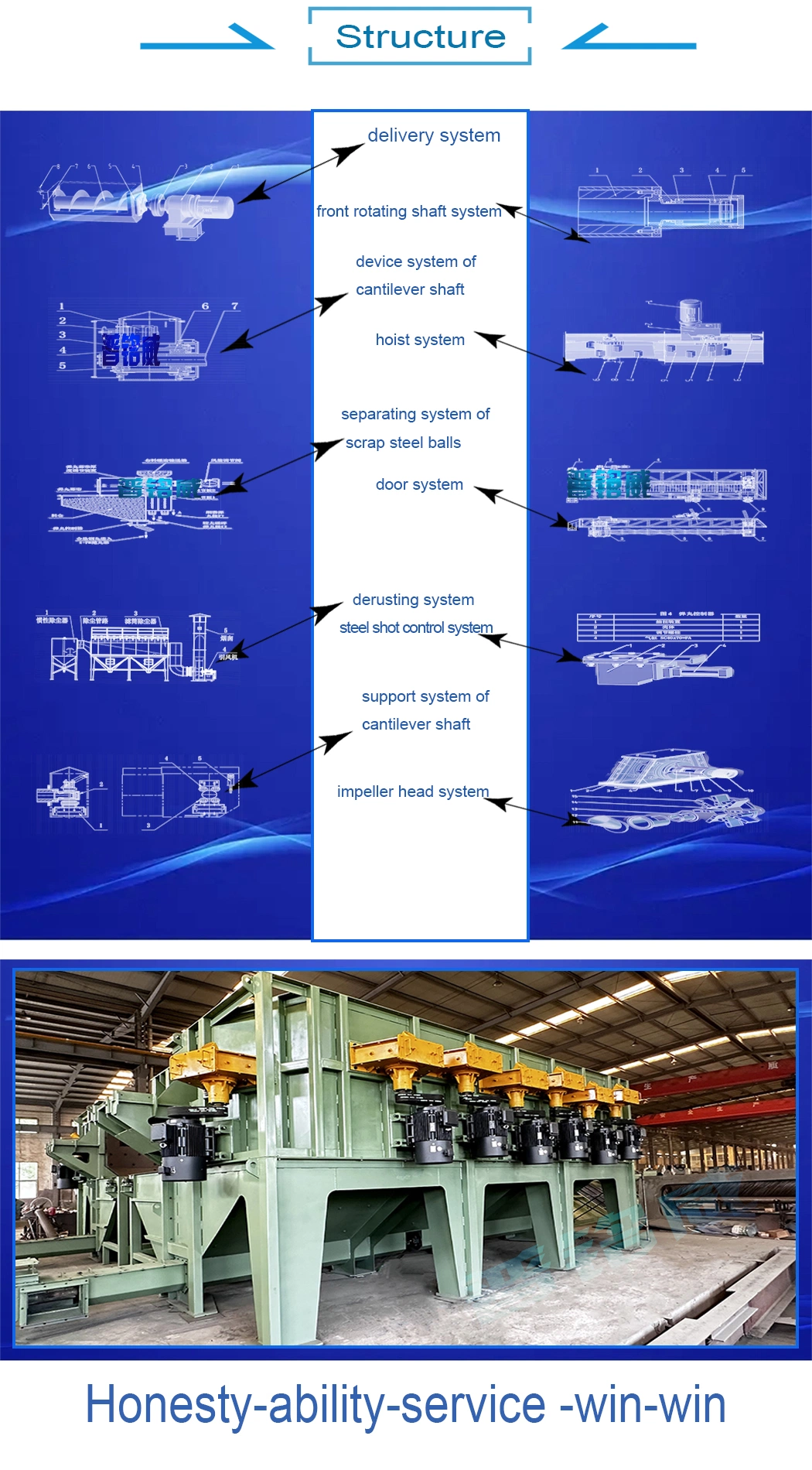

Product Description

PMW3850 type wire rod shot blasting machine is special cleaning equipment of wire rod,and using shot blasting technology to clean wire surface scale and squamous layer.the rust removal level of surface can reach Sa2.0-2.5 after the workpiece is cleared .It has characteristics of economy,pro-environment and high-efficiency compared with pickling way and without scratch on the surface of wire.

The equipment adopts a unique "turnover door+pin-ended" to carry the wire rod working mode. Simply supported shaft (pin ended)is made of special alloy steel,and the main shaft has the function of automatic dispersing the wire ,it is composed of organic whole in the normal working with pin-ended(simply supported shaft), the design of simply supported shaft greatly improves the service life of the main shaft compared with cantilever shaft .It is also a patented product of our company (patent No. : 201620372463.5). In the process of shot, the device makes wire operate compound action of up and down + side to side + positive and negative rotation to achieve the effect of thorough cleaning. The reasonable arrangement of impeller head have resulted in effective blasting of steel shot in the inner and outer surfaces of wire,the machine is controlled by PLC, and the operation is convenient and reliable.

1.Environmentally-friendly technology instead of pickling.The equipment adopts a unique "turnover door+pin-ended" to carry the wire rod working mode. Simply supported shaft (pin ended)is made of special alloy steel,and the main shaft has the function of automatic dispersing the wire ,it is composed of organic whole in the normal working with pin-ended(simply supported shaft), the design of simply supported shaft greatly improves the service life of the main shaft compared with cantilever shaft .It is also a patented product of our company (patent No. : 201620372463.5). In the process of shot, the device makes wire operate compound action of up and down + side to side + positive and negative rotation to achieve the effect of thorough cleaning. The reasonable arrangement of impeller head have resulted in effective blasting of steel shot in the inner and outer surfaces of wire,the machine is controlled by PLC, and the operation is convenient and reliable.

working principle for PMW3800 wire rod coil shot blasting machine

2.Remote control,easy operation.

3.To disperse the wire automatically,even,high effective

and lowl abor intensity for operator.

4.Ultra-low emission:3mg/m³.

5.Widely used in (high,medium,low) carbon steel,alloy

steel,stainless steel and others.

6.Good work environment and negative pressure

within equipment.

7.Can be customized according to customer products.

8.effective length is 3850mm(its updated version is PMW5550

The equipment is equipped with 8 sets impeller head according to the characteristics of wire rod,which is installed on the rear/side of the shot blasting chamber to clear the wire with 60-90secs cast speed,.By using screw horizontal conveying shot system, high strength belt hoist, steel shot residue separation system, purification dedusting system of two-stage polyester fiber filter (inertia + filter ) and (automatic + manual )HMI electric control system,it makes the workpiece meets efficient shot blasting requirements

| Application range | fasteners,wire rope,spring,stainless steel,welding rod,cold-heading wire,etc. |

| Production capacity | 40,000-100,000 each year |

| Wire diameter | 8-42mm |

| Equipment size | 9.5*6.1*6.9m(overground height) |

| Wire loss | 0.2-0.3% |

| Derusting cost | about20-40RMB/T |

| Production efficiency | 3-8coils/per hour |