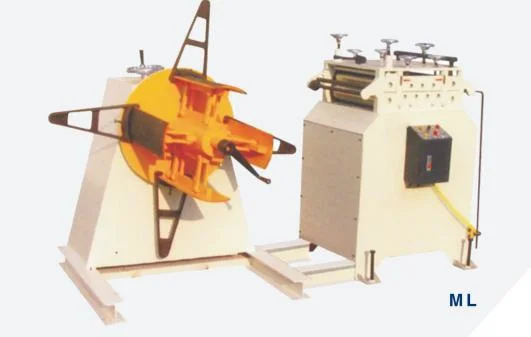

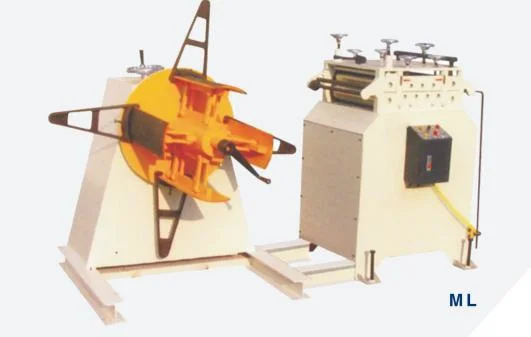

- Overview

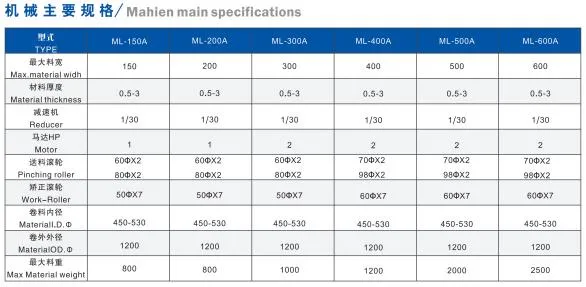

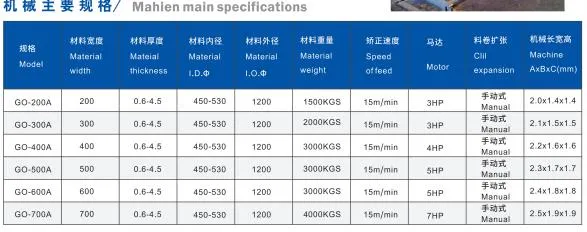

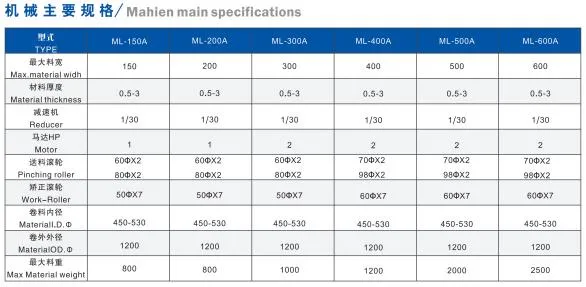

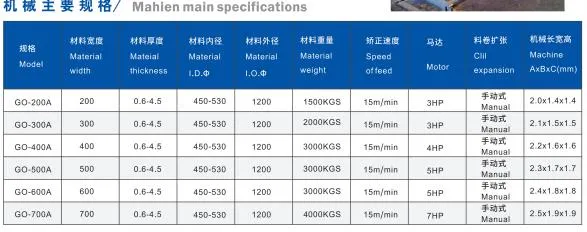

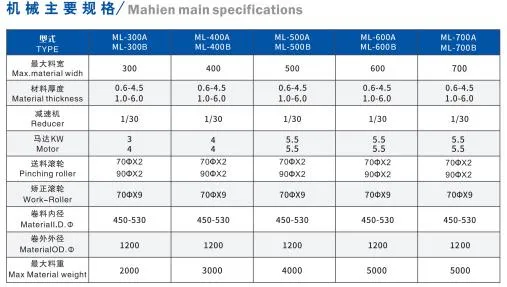

- Product Parameters

- Product Description

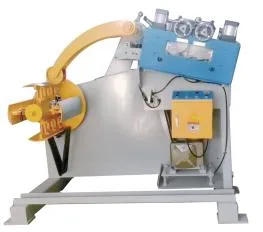

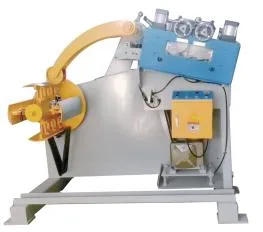

- Detailed Photos

- FAQ

Basic Info.

Model NO.

TNCF14

Automatic Grade

Automatic

Principle

Small Deformation

Certification

ISO9001, CE

Warranty

12 Months

Customized

Customized

Condition

New

Product Name

Material Feeder

Color

Customize

Width of Material

300mm

Stability

High

Capacity

Large

Feeding Speed

Fast

Applicable Material Types

Diverse

Feeding Accuracy

High

Automation Level

High

Maintenance Difficulty

Low

Energy Consumption

Low

Feeding Mode

Continuous

Control Mode

Manual/Automatic

Noise Level

Low

Footprint

Small

Transport Package

Non-Packing

Specification

standard type

Trademark

BOLI

Origin

China

HS Code

84283920

Production Capacity

5000

Packaging & Delivery

Package Size

250.00cm * 190.00cm * 190.00cm

Package Gross Weight

4000.000kg

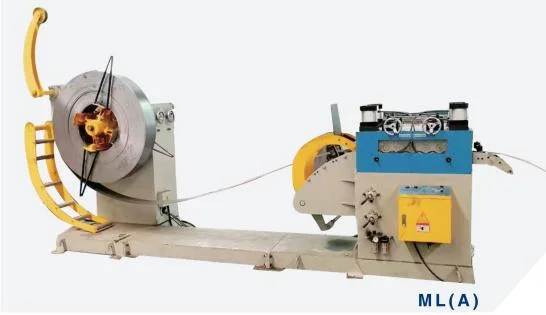

Product Description

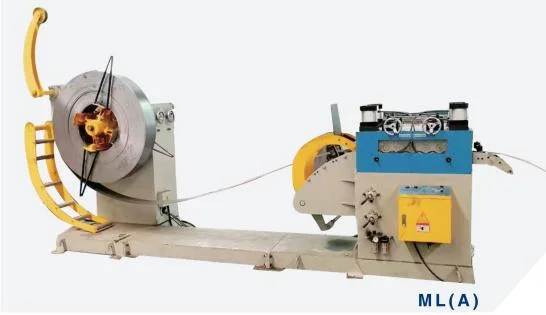

Straightener Feeder Machine

The material feeder is equipped with advanced technology and features to ensure precise and consistent material feeding. It utilizes mechanisms such as conveyor belts, augers, or pneumatic systems to transport materials from a storage container or hopper to the desired location.

This device is specifically designed to handle a wide range of materials, including powders, granules, liquids, and solids. It can accommodate different sizes, shapes, and textures, making it versatile for various production requirements.

The material feeder offers several benefits to businesses. Firstly, it improves efficiency by automating the feeding process, reducing the need for manual labor and minimizing the risk of human error. Secondly, it enhances accuracy and consistency, ensuring that the correct amount of material is delivered every time.

Additionally, the material feeder enhances safety by minimizing the contact between operators and potentially hazardous materials. It also reduces waste and spillage, contributing to a cleaner and more environmentally friendly work environment.

The material feeder can be integrated into existing production lines or customized to meet specific requirements. It is often equipped with sensors and controls to monitor and adjust the feeding process, ensuring optimal performance and preventing issues such as clogging or overfeeding.

In summary, the material feeder is a vital component in industrial settings, providing reliable and efficient material delivery. With its precision, versatility, and automation capabilities, it contributes to improved productivity, accuracy, and safety in various production processes.

A1: A Material Feeder is a device used to deliver or supply materials in a controlled and precise manner to a processing or production system.

Q2: What types of materials can a Material Feeder handle?

A2: Material Feeders can handle a wide range of materials, including powders, granules, pellets, flakes, and liquids.

Q3: How does a Material Feeder ensure feeding accuracy?

A3: Material Feeders employ various mechanisms such as augers, belts, vibratory trays, or pneumatic systems to control the flow and ensure accurate feeding of materials.

Q4: What are the benefits of using an automated Material Feeder?

A4: Automated Material Feeders offer advantages such as improved efficiency, reduced labor costs, consistent feeding rates, precise control over material flow, and integration with other automated systems.

Q5: How can a Material Feeder contribute to production stability?

A5: Material Feeders help maintain a consistent and uninterrupted supply of materials, minimizing production downtime and ensuring stable output.

Q6: What maintenance is required for a Material Feeder?

A6: Regular cleaning, inspection, and lubrication are necessary to maintain optimal performance of Material Feeders. Additionally, parts replacement and calibration may be required periodically.

Q7: Can a Material Feeder handle materials with varying viscosities?

A7: Yes, Material Feeders can be designed to handle materials with a wide range of viscosities, from free-flowing liquids to highly viscous pastes or gels.

Q8: Are Material Feeders customizable to specific production requirements?

A8: Yes, Material Feeders can be customized to meet specific production needs, including capacity, feeding speed, feeding mode, control options, and integration with other equipment.

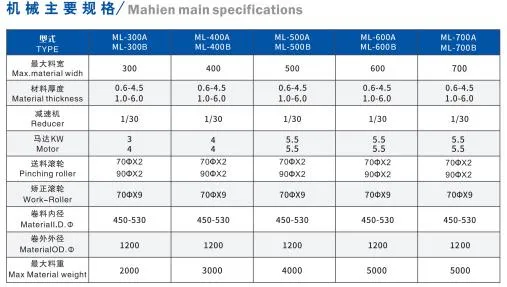

| Specification | SL-300A |

| width of material | 300mm |

| thickness of material | 0.6-4.5 |

| max.coil weight(T) | 2000kg |

| coil l.D(mm) | 508 |

| max.coil O D.(mm) | 1200 |

| max speed(m/min)16 | 15 |

The material feeder is a device designed to accurately and efficiently deliver materials to a production line or machine. It plays a crucial role in various industries, including manufacturing, packaging, and food processing.

The material feeder is equipped with advanced technology and features to ensure precise and consistent material feeding. It utilizes mechanisms such as conveyor belts, augers, or pneumatic systems to transport materials from a storage container or hopper to the desired location.

This device is specifically designed to handle a wide range of materials, including powders, granules, liquids, and solids. It can accommodate different sizes, shapes, and textures, making it versatile for various production requirements.

The material feeder offers several benefits to businesses. Firstly, it improves efficiency by automating the feeding process, reducing the need for manual labor and minimizing the risk of human error. Secondly, it enhances accuracy and consistency, ensuring that the correct amount of material is delivered every time.

Additionally, the material feeder enhances safety by minimizing the contact between operators and potentially hazardous materials. It also reduces waste and spillage, contributing to a cleaner and more environmentally friendly work environment.

The material feeder can be integrated into existing production lines or customized to meet specific requirements. It is often equipped with sensors and controls to monitor and adjust the feeding process, ensuring optimal performance and preventing issues such as clogging or overfeeding.

In summary, the material feeder is a vital component in industrial settings, providing reliable and efficient material delivery. With its precision, versatility, and automation capabilities, it contributes to improved productivity, accuracy, and safety in various production processes.

Q1: What is a Material Feeder?

A1: A Material Feeder is a device used to deliver or supply materials in a controlled and precise manner to a processing or production system.

Q2: What types of materials can a Material Feeder handle?

A2: Material Feeders can handle a wide range of materials, including powders, granules, pellets, flakes, and liquids.

Q3: How does a Material Feeder ensure feeding accuracy?

A3: Material Feeders employ various mechanisms such as augers, belts, vibratory trays, or pneumatic systems to control the flow and ensure accurate feeding of materials.

Q4: What are the benefits of using an automated Material Feeder?

A4: Automated Material Feeders offer advantages such as improved efficiency, reduced labor costs, consistent feeding rates, precise control over material flow, and integration with other automated systems.

Q5: How can a Material Feeder contribute to production stability?

A5: Material Feeders help maintain a consistent and uninterrupted supply of materials, minimizing production downtime and ensuring stable output.

Q6: What maintenance is required for a Material Feeder?

A6: Regular cleaning, inspection, and lubrication are necessary to maintain optimal performance of Material Feeders. Additionally, parts replacement and calibration may be required periodically.

Q7: Can a Material Feeder handle materials with varying viscosities?

A7: Yes, Material Feeders can be designed to handle materials with a wide range of viscosities, from free-flowing liquids to highly viscous pastes or gels.

Q8: Are Material Feeders customizable to specific production requirements?

A8: Yes, Material Feeders can be customized to meet specific production needs, including capacity, feeding speed, feeding mode, control options, and integration with other equipment.