- Overview

- Product Description

- Product Parameters

- Packaging & Shipping

- After Sales Service

Basic Info.

Model NO.

WDTP-01

Supply Reel Dia

76mm I.D. Standard - Other Sizes Available.

Net Weight

45kg

Certificate

CE

Transport Package

Paper Carton with Wooden Cases

Specification

WDTP-01

Trademark

Windoo

Origin

China

HS Code

84798110

Production Capacity

5000

Packaging & Delivery

Package Size

25.00cm * 55.00cm * 30.00cm

Package Gross Weight

30.000kg

Product Description

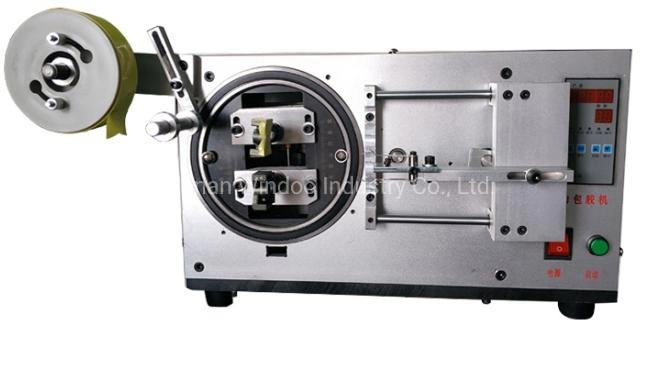

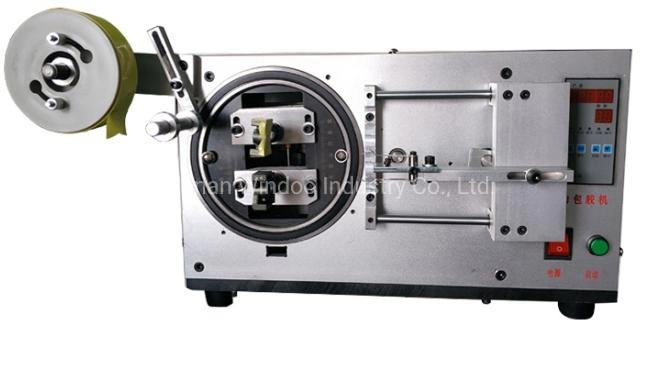

CNC full Automatic Copper Wire Coil Tape Winding Machine

AUTOMATIC COIL TAPING MACHINE WDTP-01

Supply reel dia:

76mm I.D. standard - other sizes available.

Changeable Parts:

Tape roller attachment, winding jigs (tooling), cutter and wiper fixture, safety cover, tape backing removal feature.

Power

AC 230 / 110 V ± 10%, 50 - 60hz

Dimensions

600 L * 650 W * 300 H (mm)

Net weight

45 kg

CE certificate

Application:

The coil is placed by an operator on a rotating spindle, and the machine automatically applies the required number of turns of insulation tape, secures the end of the tape with a wiping action, and ejects the coil from the machine.

This taping machine is ideal for larger batch quantities of coils, with very high repeatability and fast cycle times.

Taping of ferrite cores, EI laminations, and wound coils.

A high-speed automatic coil taping machine for the application of insulation tape to wound coils and other electronic components.

The machine is designed to operate with a wide variety of insulation tapes, including Kapton, Polyester, PEN, PVC, and most other woven and non-woven types.

Features:

1. Two-axis tape wrap, suitable for EEEFPQ, and SMD transformer wraps magnetic cores

2. The position of the adhesive arrangement can be fine-tuned, and the gravitational device can be adjusted;

3. Different products must be replaced with different fixtures

4. CNC-130 controller control, more stable and convenient:

5. Light-sensing positioning, remove the fragile, and short-life characteristics of micro switches,reduce maintenance, improve efficiency and reduce costs

Wooden case package: For larger scale goods such as machine equipment etc, we have a special skilled carpenter, who would make the proper wooden case with exact thickness, density, and length. The up arrow ↑marked on the outer wooden case. Buffer material would be put in the wooden case to prevent cracks and shock. We will inform you of the delivery note. You just need to wait for a phone call, then pick up the goods at the nearest logistic station. (Please let me know in advance if you want to get the goods at home.)

Shipping:

A. 3-5 workdays shipping from China by Air/Express(DHL, FedEx, UPS, EMS, etc.)

B. 3-5 workdays shipping from UK Warehouse to European union countries.No need to pay for customs duties and VAT.

C. 25-30 workdays shipping from China to Russian customers. No need to pay for customs duties and VAT.

D. We can arrange shipment by sea. Minium CBM requirement : 1 CBM

2.24 hours of technical support by email or call.

3. Warranty: 1 year free, 2-3 years cost price, and free technical support always.

4. Free training to make sure you master the operation of our products.

5. OEM/ODM accept. But the MOQ of OEM/ODM is 100 sets.

Service tenet

Provide you the best service with "fast + satisfactory + safe".

Warranty period:

12 months long after the user received the product.

AUTOMATIC COIL TAPING MACHINE WDTP-01

This machine is controlled by a microcomputer program and driven by a deceleration motor, which ensures the stability of the machine Intelligent control system: dual display windows, A shows the number of laps required for setting, and B shows the output of the work (the output can be cleared).

Min. Bobbin Size:

12mm of wound coil cross-section.Supply reel dia:

76mm I.D. standard - other sizes available.

Changeable Parts:

Tape roller attachment, winding jigs (tooling), cutter and wiper fixture, safety cover, tape backing removal feature.

Power

AC 230 / 110 V ± 10%, 50 - 60hz

Dimensions

600 L * 650 W * 300 H (mm)

Net weight

45 kg

CE certificate

Application:

The coil is placed by an operator on a rotating spindle, and the machine automatically applies the required number of turns of insulation tape, secures the end of the tape with a wiping action, and ejects the coil from the machine.

This taping machine is ideal for larger batch quantities of coils, with very high repeatability and fast cycle times.

Taping of ferrite cores, EI laminations, and wound coils.

A high-speed automatic coil taping machine for the application of insulation tape to wound coils and other electronic components.

The machine is designed to operate with a wide variety of insulation tapes, including Kapton, Polyester, PEN, PVC, and most other woven and non-woven types.

Features:

1. Two-axis tape wrap, suitable for EEEFPQ, and SMD transformer wraps magnetic cores

2. The position of the adhesive arrangement can be fine-tuned, and the gravitational device can be adjusted;

3. Different products must be replaced with different fixtures

4. CNC-130 controller control, more stable and convenient:

5. Light-sensing positioning, remove the fragile, and short-life characteristics of micro switches,reduce maintenance, improve efficiency and reduce costs

Packaging & Shipping

General package(Paper carton or plastic bag): For small goods, Package it with form and pack paper to guarantee unbroken during the transport.Wooden case package: For larger scale goods such as machine equipment etc, we have a special skilled carpenter, who would make the proper wooden case with exact thickness, density, and length. The up arrow ↑marked on the outer wooden case. Buffer material would be put in the wooden case to prevent cracks and shock. We will inform you of the delivery note. You just need to wait for a phone call, then pick up the goods at the nearest logistic station. (Please let me know in advance if you want to get the goods at home.)

Shipping:

A. 3-5 workdays shipping from China by Air/Express(DHL, FedEx, UPS, EMS, etc.)

B. 3-5 workdays shipping from UK Warehouse to European union countries.No need to pay for customs duties and VAT.

C. 25-30 workdays shipping from China to Russian customers. No need to pay for customs duties and VAT.

D. We can arrange shipment by sea. Minium CBM requirement : 1 CBM

Service

1. We provide you a friendly English User manual or operating videos for free.2.24 hours of technical support by email or call.

3. Warranty: 1 year free, 2-3 years cost price, and free technical support always.

4. Free training to make sure you master the operation of our products.

5. OEM/ODM accept. But the MOQ of OEM/ODM is 100 sets.

Service tenet

Provide you the best service with "fast + satisfactory + safe".

Warranty period:

12 months long after the user received the product.