- Overview

- Company Profile

- Product Description

- Detailed Photos

- WHY CHOOSE US

- Our Advantages

- Packaging & Shipping

- Certifications

- FAQ

Basic Info.

Packaging & Delivery

Product Description

Established in 1993, Luoyang Ruichuang Electrical Equipment Co, Ltd. is located in the High-techDevelopment Zone of China (Henan) Free Trade Zone. it is a high-tech enterprise integrating R8D, desigrmanutacture. insta ation and service. The companv has advanced manacement con cents, hioh-oualittalents, first-class research and development capabilities, advanced processing equipment, completeproduction chain, strict quality inspection system, and professional service team. nnovation is theinexhaustible driving force for our development. Since its establishment in 1993, our company has beercommitted to the development of high and low voltage power distribution equioment, sheet metaprocessing equipment (polyurethane foam sealing and coating equipment, industrial fat inkjet printingequioment, welding automation equioment), customized automation Solutions, robots, etc. The vears otexperience and technology accumulation in the sheet metal industry enable Ruichuang to providecustomers with the most efficient and flexible automation solutions.The product has high degree ofautomation, reliable performance and simple operation, and has gained trust and support from customersat home and abroad.

Established in 1993, Luoyang Ruichuang Electrical Equipment Co, Ltd. is located in the High-techDevelopment Zone of China (Henan) Free Trade Zone. it is a high-tech enterprise integrating R8D, desigrmanutacture. insta ation and service. The companv has advanced manacement con cents, hioh-oualittalents, first-class research and development capabilities, advanced processing equipment, completeproduction chain, strict quality inspection system, and professional service team. nnovation is theinexhaustible driving force for our development. Since its establishment in 1993, our company has beercommitted to the development of high and low voltage power distribution equioment, sheet metaprocessing equipment (polyurethane foam sealing and coating equipment, industrial fat inkjet printingequioment, welding automation equioment), customized automation Solutions, robots, etc. The vears otexperience and technology accumulation in the sheet metal industry enable Ruichuang to providecustomers with the most efficient and flexible automation solutions.The product has high degree ofautomation, reliable performance and simple operation, and has gained trust and support from customersat home and abroad.  High Efficiency Automatic Cnc Stud Welding System For M3-M8 is the latest CNC equipment that integrated automatic stud feeding and welding, developed based on traditional manual stud welding machine, integrated with independent R&D automatic stud feeding mechanism,automatic welding head, automatic control system and etc. The machine can equip with multiple welding heads and weld multi-specification studs which can replace manual welder, positioning accuracy, welding firmly, wide application materials: cold plate,stainless steel,aluminium,galvanized plates and etc.

High Efficiency Automatic Cnc Stud Welding System For M3-M8 is the latest CNC equipment that integrated automatic stud feeding and welding, developed based on traditional manual stud welding machine, integrated with independent R&D automatic stud feeding mechanism,automatic welding head, automatic control system and etc. The machine can equip with multiple welding heads and weld multi-specification studs which can replace manual welder, positioning accuracy, welding firmly, wide application materials: cold plate,stainless steel,aluminium,galvanized plates and etc.

High Efficiency Automatic Cnc Stud Welding System For M3-M8 can weld multi-specification studs on the metal surface quickly and stably, without sunk, bulge on the backside of plate, and no need the traditional processes of drilling,riveting, arc welding and post treatment; which can realize the complicated welding requirements by CNC programming. Stud welding Technology greatly increase the production efficiency, reduces the production costs and improves the quality. CNC automated stud welding equipment is a kind of automatic equipment dev eloped for customers to solve the studs mass welding. With the rising labor costs of today's factories, a product requires mor re and more varieties and quantities of welding studs, while the production task is showing a trend of small batches and more varieties, this automation equipment can meet the production needs of these products, and gradually become the standard equipment of sheet metal factories and metal processing plants.

CNC automated stud welding equipment is a kind of automatic equipment dev eloped for customers to solve the studs mass welding. With the rising labor costs of today's factories, a product requires mor re and more varieties and quantities of welding studs, while the production task is showing a trend of small batches and more varieties, this automation equipment can meet the production needs of these products, and gradually become the standard equipment of sheet metal factories and metal processing plants. When manual feeding floating ball rise, to avoid the workpiece (especially stainless steel plate) on the insulation platformfriction caused by surface scratches, manual loading and unloading save time and labor, according to the needs ofcustomer products can be set A. B station. to achieve A. B station atemate use, creatly improve the production eficencyWhen working, the floating ball falls, the clamp clamp the workpiece and is reliably grounded;

When manual feeding floating ball rise, to avoid the workpiece (especially stainless steel plate) on the insulation platformfriction caused by surface scratches, manual loading and unloading save time and labor, according to the needs ofcustomer products can be set A. B station. to achieve A. B station atemate use, creatly improve the production eficencyWhen working, the floating ball falls, the clamp clamp the workpiece and is reliably grounded;

The circular moving positionina block is easy to fx any shape of the workoiece, and can locate the outer and inner holes otthe workpiece;

The table is evenly distributed and modular installation of dovetai croove. and the installation position of the positioning blockof the pneumatic clamp can be adiusted at will;

| Model No. | RC-Z-2212 | Drive Method | Servo motor pneumatic |

| Max. Working Stroke | 2200mmx1200mmx300 mm | Z-axis travel | Pneumatic, 150 mm |

| Overall Dimension (L*W*H) | 4100x2200x 2400 mm | Z-axis travel | Servo, 150mm |

| X Y Fastest moving speed | 55 m/min | Z fastest moving speed | 15 m/min |

| Stud diameter (mm) | M3-M10, can be customized | Energy storage Welder | 1 pc |

| Stud length (mm) | 8-35 mm, can be customized | Automatic welding head | standard: 3 or 6. can becustomized |

| Welding head | 3-6 pcs | Number of mobile clamps | 4 |

| Welding accuracy | ±0.15 mm | Welding speed | 25 35pcs/min |

| Gas source - Gas consumption | 0.3 m3/min | Automatic stud feeder/set | 3, can be customized |

The automatic stud feeding device is composed of a vibrating disk nail selector + pneumatic nail feedingmechanism + automatic welding gun + stud feeding tube.

The automatic stud feeding device is composed of a vibrating disk nail selector + pneumatic nail feedingmechanism + automatic welding gun + stud feeding tube. It can realize automatic nail delivery and welding, high reliabilty of nail delivery, automatic detection of thepresence or absence of nails, improved system efficiency and reliability, simple and reasonable desigrstructure. stable and reliable.

The special nail feeding mechanism has the characteristics of large carrying capacity, low noise, energysaving and consumption reduction.

The stud feeding system specification is M3-M8, 10-35mm long welding studs can be optional for one set ofmechanism. (non-standard can be customized).

Can be equipped with multiple welding guns at the same time welding a varety of specifications of screwsautomatic stud feeding, automatic welding, and no drilling, riveting, arc welding and post-weldingprocessing and other cumbersome traditional processes, can be welded 25 to 30 studs per minute.saving time and effort.

Can be equipped with multiple welding guns at the same time welding a varety of specifications of screwsautomatic stud feeding, automatic welding, and no drilling, riveting, arc welding and post-weldingprocessing and other cumbersome traditional processes, can be welded 25 to 30 studs per minute.saving time and effort. The automatic welding gun is the terminal actuator of theautomatic stud welding equipment. Through the repeatedaction of the welding gun, the welding studs are quicklywelded to the plate one by one. There are generally twokinds of automatic welding gun classification in the market.our company is generally divided into direct feeding gunand oblique feeding gun according to the way of studfeeding, the development of direct feeding gun and obliquefeeding gun on the basis of foreign companies, re researchand development, adjust the structure, developed to adaptto the actual production envronment and conditions ofdomestic customers welding gun,can adapt to theconsistency requirements are not too high welding nails.Developed can adapt to a variety of welding studs at thesame time without personnel too much adjustment of theautomatic welding torch, can adapt to pull arc and energystorage dual function welding torch,there are somecustomized non-standard welding guns,such as thewelding gun which feed the studs from the bottom up.automatic gun change head welding gun, etc., can adaptto different kinds of products welding, in the functionincrease at the same time compared with foreignequipment prices falls, It is convenient for our customers touse this automatic welding method.

Welding torch comes standard with 3 heads (1-3 gunheads can be installed) and 6 heads (4-6 gun heads canbe installed),and can also be equipped with specialmachine heads.

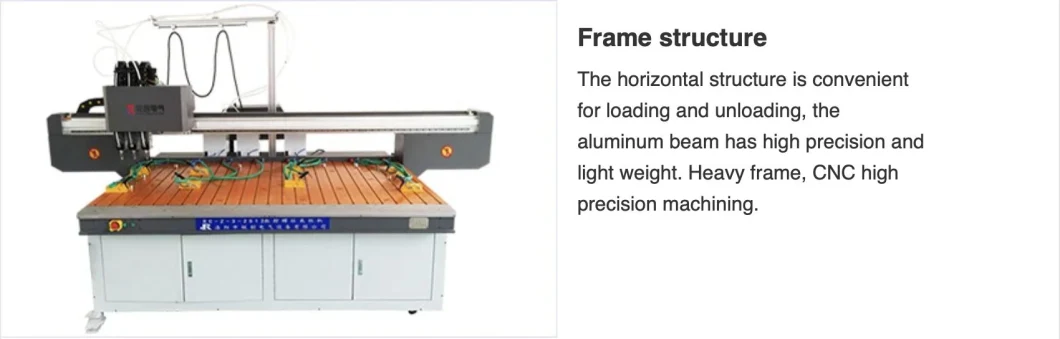

The horizontal structure is convenientfor loading and unloading, thealuminum beam has high precision andlight weight. Heavy frame, CNC highprecision machining.

The horizontal structure is convenientfor loading and unloading, thealuminum beam has high precision andlight weight. Heavy frame, CNC highprecision machining.  High-precision belt drive, double servodrive, high precision and fast speed themaximum running speed can reach 60m/s.

High-precision belt drive, double servodrive, high precision and fast speed themaximum running speed can reach 60m/s.  Various programming methods supportteaching / laser point / CAD and so on.The handheld box with touchscreen isconvenient and flexible.

Various programming methods supportteaching / laser point / CAD and so on.The handheld box with touchscreen isconvenient and flexible.  The welding platform is composed ofinsulated bakelite, air cylinder, floatingball and pneumatic clamp. Thetightening device is a mobile clampThe tightening height, angle, andposition can be adiusted arbitrarilvaccording to the size of the workpiece.and it can clamp the workpiece withfolded edges.

The welding platform is composed ofinsulated bakelite, air cylinder, floatingball and pneumatic clamp. Thetightening device is a mobile clampThe tightening height, angle, andposition can be adiusted arbitrarilvaccording to the size of the workpiece.and it can clamp the workpiece withfolded edges.  Double-capacity welding machine withcommunication, the life is twice as longas others, one group can be switched toanother group if there is a failure. Onewelder can be equipped with 6 weldingguns.

Double-capacity welding machine withcommunication, the life is twice as longas others, one group can be switched toanother group if there is a failure. Onewelder can be equipped with 6 weldingguns.  Ruichuang machine have A&B twowork stations. When the A stationworkpiece is welded, the system willautomatically weld the B station

Ruichuang machine have A&B twowork stations. When the A stationworkpiece is welded, the system willautomatically weld the B station workpiece which can realize thealternate use of A and B stations. whichgreatly improves production efficiency.

The factory has passed ISO 9001 quality management system certification, with perfect technology, qualityand inspection control ability, to ensure that the whole process from raw materials into the factoryproduction and processing to finished products factory control.

Q1. Are you factory or trading company?

We are professional factory in Sheet metal industry and CNC machinery industry with near 30 vears ofexperience, covering sheet metal fabrication, CNC pu foam sealing machine, CNC stud welding machineindustrial Robot industrial Flatbed Inkiet Printer etc

Q2. How long is the lead time?

Normally 20 to 30 working days

Q3. How long is the warranty of your machines?

Generally 1 year.

Q4. What shipment ways do you support?

By sea, by air, by train, by international express, etc.

Q5. What payment terms do you accept?

We accept T/T, L/C, Alibaba trade assurance order, etc.

Q6. Does the machine support customization?

Yes, our machines support customization.

Our service:

1. We offer a 24-hour online service.

2. We provide free remote training, operating guide, remote/onsite technical support, etc

3.We accept OEM and ODM.