Basic Info.

Model NO.

Metal Stamping Parts

Processing Type

Shaping Metal

Material

Stainless Steel

Mould

Simple Single Process Dies

Surface Processing

Electroplating

Fine Blanking

Open

Process

Forming Process

Industry

Metal Stamping Parts

Tolerances

0.2mm

Customized

Customized

Surface Treatment

Electroplating/Spraying/Polishing/Oxidation/Galvan

Delivery

Sea, Air, or Express

Quality

Excellent

Color

Customized Color

Transport Package

Carton Box + Wooden Case

Specification

Customizable Size

Trademark

Hengjin

Origin

China

HS Code

7326901000

Production Capacity

50000/Month

Packaging & Delivery

Package Size

12.00cm * 5.00cm * 2.00cm

Package Gross Weight

0.200kg

Product Description

Custom Sheet Metal Fabrication Services

We are excited to introduce our new custom sheet metal fabrication services to you. Our products are designed to meet the unique needs of your business and provide you with the highest quality metal stamping parts.

Our factory specializes in fine blanking services and stainless steel metal stamping parts. We use the latest technology and equipment to ensure that our products are of the highest quality. Our team of experts is dedicated to providing you with the best possible service and support.

Our custom sheet metal fabrication services are perfect for businesses that require precision and accuracy. We can create parts that are tailored to your specific needs and requirements. Our products are made from high-quality materials and are built to last.

We understand that every business is unique, which is why we offer a range of customization options. Whether you need a specific size, shape, or design, we can create a product that meets your needs. Our team is always happy to help and answer any questions you may have.

Please do not hesitate to contact us if you have any questions or would like to place an order. We are always happy to help and look forward to hearing from you soon.

Thank you for considering our custom sheet metal fabrication services. We look forward to working with you.

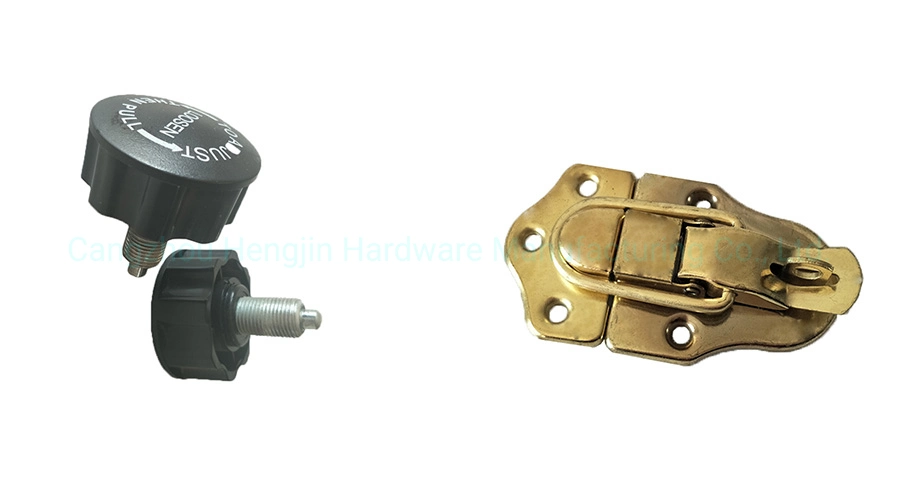

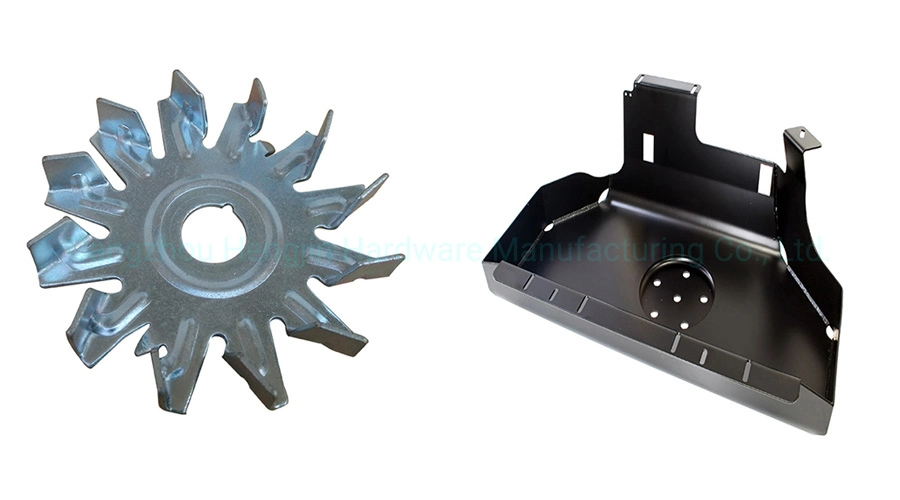

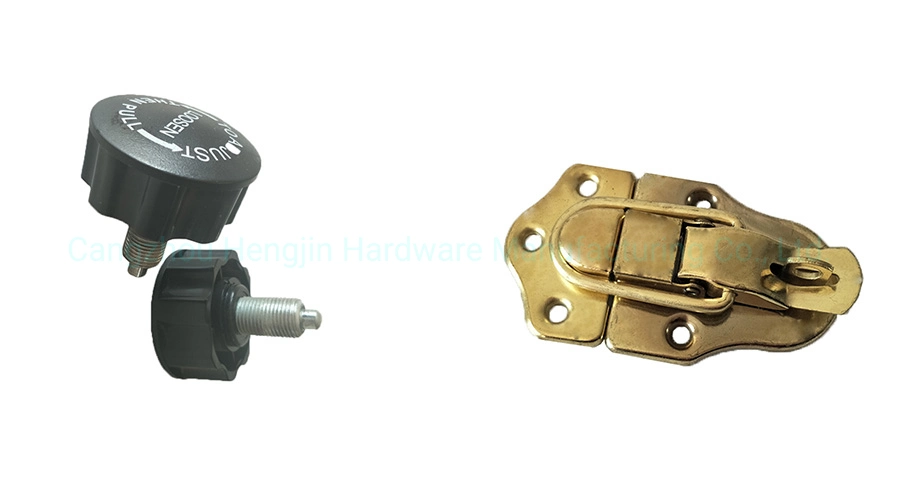

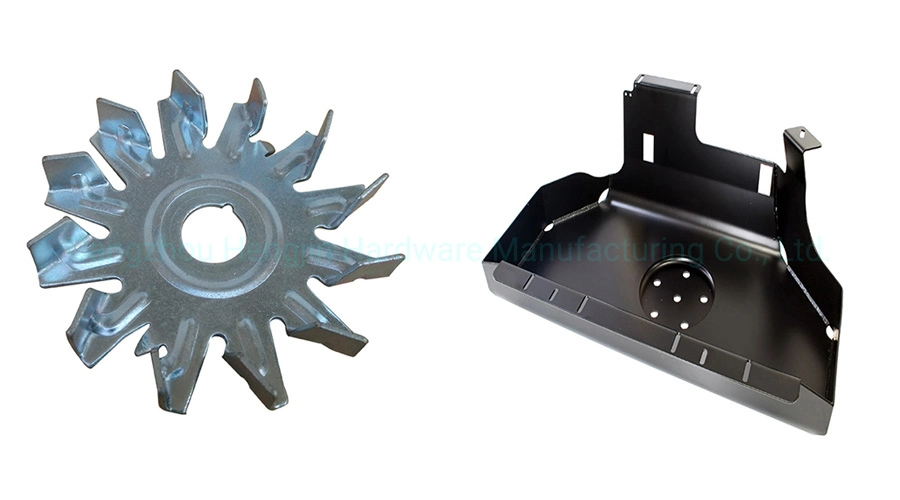

Related Products :

Custom Metal Fabrication Product Descriptions:

Our ability:

ONE-STOP SERVICE:

ONE-STOP SERVICE:

Company profile:

Machine list :

FAQ

Q: How soon can I get reply after send inquiry?

A:All inquiries will be replied within two hours except sleeping time in China.

Q: How soon can I get samples ?

A: The drawing determines the length of time,Generally samples can be sent out within 10 working days after product drawing confirmed by both side.

Q: What file format can you accept for my products?

A: 1.We can accept varies format, step, stp, jpg,pdf, dwg, dxf,3d and so on.

2.If you do not have a prepared CAD file, we can accept a scan of a hand drawn design.

Q: If I don't have drawing, how can I get sample ?

A: If you don't have any drawing,you can send us your sample, we will scan it and make 2D and 3D drawing first, then make sample for you.

Q: What are many common materials that you use in projects?

A: Aluminum,Stainless Steel, Carbon Steel, Copper, Plastics and so on.

Q: What's your MOQ(minimum order quantity?

A: Our MOQ is 100 pcs, you are welcome to send us trial order to test our quality and service.

Q: What's the payment term do you accept?

A: EXW/FOB Tianjin, paid by T/T, Western Union.

We are excited to introduce our new custom sheet metal fabrication services to you. Our products are designed to meet the unique needs of your business and provide you with the highest quality metal stamping parts.

Our factory specializes in fine blanking services and stainless steel metal stamping parts. We use the latest technology and equipment to ensure that our products are of the highest quality. Our team of experts is dedicated to providing you with the best possible service and support.

Our custom sheet metal fabrication services are perfect for businesses that require precision and accuracy. We can create parts that are tailored to your specific needs and requirements. Our products are made from high-quality materials and are built to last.

We understand that every business is unique, which is why we offer a range of customization options. Whether you need a specific size, shape, or design, we can create a product that meets your needs. Our team is always happy to help and answer any questions you may have.

Please do not hesitate to contact us if you have any questions or would like to place an order. We are always happy to help and look forward to hearing from you soon.

Thank you for considering our custom sheet metal fabrication services. We look forward to working with you.

Related Products :

Custom Metal Fabrication Product Descriptions:

| Manufacturing Process | Laser cutting/NCT/Punching, sharping, bending, threading, welding, polishing, tapping, riveting, surface finishing, assembly, pacing |

| Material | Stainless steel, SPCC/SGCC, copper/brass, aluminum for option (according to customer's requirements for special material) |

| Surface Treatment | Galvanized (zinc-plated, nickel-plated, chrome-plated, silver-plated), powder coating/oil painting, polishing (mirror polishing, electrolytic polishing), brushing, sand blasting, hot-dip galvanized |

| Tolerance | +/-0.01mm or special requirements |

| packaging | PE Bag, Paper carton box, plywood case/pallet/crate |

| Application | Auto parts, electronic products, power supply, industry cabinet, construction etc |

| Quality Control | ISO9001 |

| Drawing File Format | PDF,JPG,CAD,3D |

| Features | Customized Design Sample Order Accepted Short Delivery time Competitive Prices Long time quality Insurance Professional after-sale services |

| Inspection | IQC, PQC, FQC, OQA |

| Delivery time | 15-30days |

| Quality Insurance | One Year |

| Delivery | By sea, by air, by land, by courier |

Our ability:

| Fastener | |

| Main Varieties | 1.Screws, Nuts, Bolts, Washers,hinges 2.Standard fasteners and no-standard fasteners are all available 3.Solidworks, STEP, IGS, AutoCAD |

| Equipment Capacity | 60 sets screws manufacturing machines. |

| Material | Carbon Steel, Stainless Steel, Brass, Aluminum, etc. |

| Additional Services | Finishing: Cleaning, deburring, heat treating, plating, Anodizing Assembly: Riveting, welding, tapping, staking |

| Spring | |

| Main Varieties | Compression spring Wire bend form spring/hook Torsion spring Extension spring Spiral Spring |

| Equipment Capacity | 18 sets CNC spring machines |

| Materials | Spring Steel wire, steel wire, stainless steel wire, music wire or other available material. |

| Wire diameter | 0.1mm to 6.0mm |

| Tolerances | 001" (.025mm) |

| Stamping | |

| Capabilities | 1.Progressive / Fourslide stamping 2.In-die tapping 3.Professional manufacturing department for OEM / ODM Toolings/Moulds |

| Press Capacity | 10 to 250 tons |

| Equipment Capacity | 40 sets stamping machines |

| Aplications | Brackets,Clamps,Clips,Connectors Contacts,Cups,Flat springs,Levers Mounting plates,Retainers,Strain Reliefs Terminals,etc. |

| Additional Services | Finishing: Cleaning, deburring, heat treating, plating Assembly: Riveting, welding, tapping, staking Prototype stamping |

| Deep drawing | |

| Material available | Carbon steel(CRS/SPCC, SECC, etc), Stainless steel, spring steel, Bronze(berylium, phosphor, etc), brass, copper alloy, aluminum alloy, tinplate, nickel silver, plastic |

| Surface treatment available | Zinc/nickel/chrome/tin plating(colour or natural), Galvanization, anodizing, oil spraying, powder coating, polishing, passivate, brush, wire drawing, etc. |

| Metal processing available | Stamping parts:Tooling making, samples approval, cutting, stamping, punching, tapping, welding, bending and forming, finishing, assembly CNC parts:CNC lathe milling, CNC lathe turning, drilling, tapping, finishing, assembly, packing |

Specification | OEM/ODM, make per customer' s drawing or sample |

Tolerance | Stamping parts:0.01-0.1mm, CNC machining parts:0.1-0.002mm |

| Cnc Machining | |

| Capabilities | CNC Milling, CNC lathe / turning CNC Turning with Live Tooling Solidworks, STEP, IGS, AutoCAD Multi-Axis Aircraft Machining |

| Equipment Capacity | 20 sets 3 / 4 Axis CNC Milling Machines, 40 stes CNC lathe / turning machines |

| Materials | Aluminum to Hardened Steels and Exotic Alloys, Plastic, Brass, etc. |

| Additional Services | Finishing:Anodized, Cleaning, deburring, heat treating, plating Assembly: Riveting, welding, tapping, staking Prototype available |

ONE-STOP SERVICE:

ONE-STOP SERVICE:

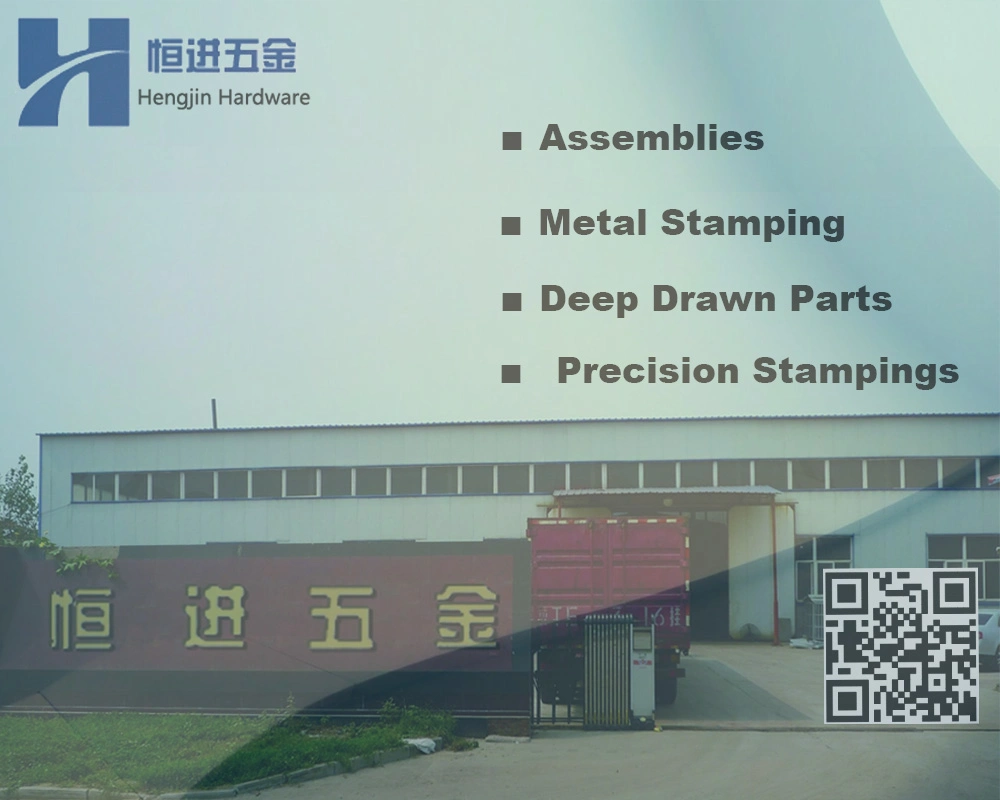

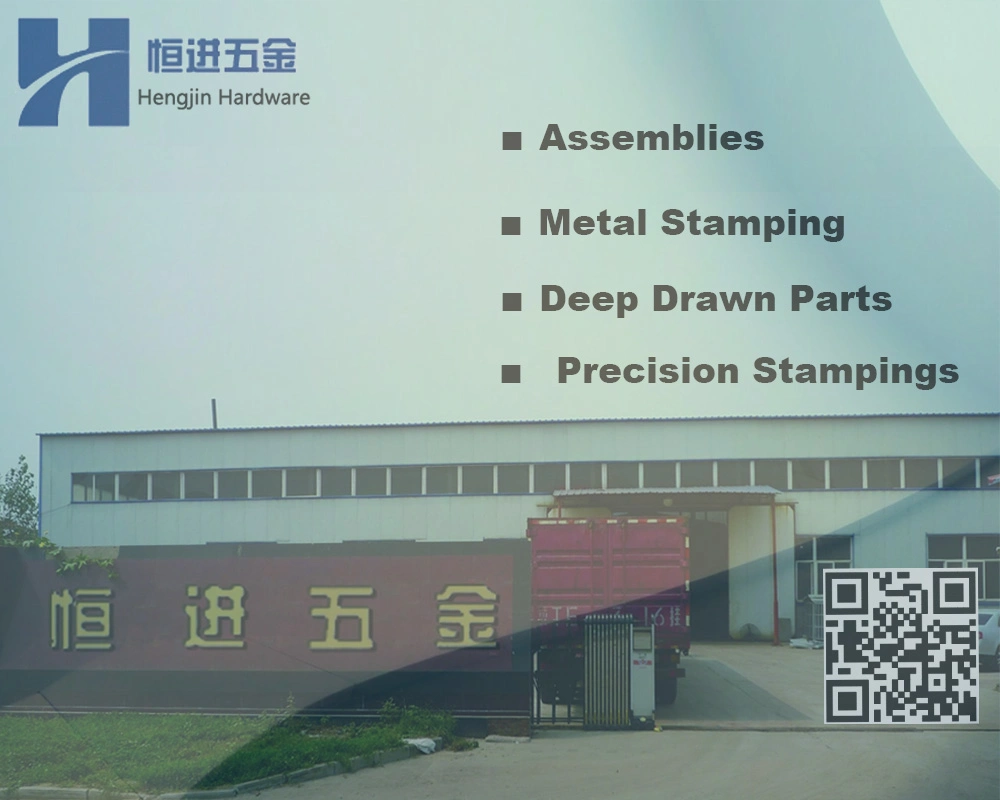

Company profile:

We are a professional production factory specialized in sheet metal fabrication mainly stamping, deep drawing, welding and wire bending.

We have our own equipments for a whole production flow, from mould design, prototypes develop, processing, assembly to surface coating. We have a high level team of engineers to provide you with the most practical and cost-effective solutions. Our workers are experienced and our quality control is strict. We have the ability to provide clients with high quality and low price products. Aligning ourselves with purchasers in the same vision of providing superior quality, has contributed to our success. Also honesty is our best policy. Our philosophy is simple: we deliver our promises.

If you are looking for a manufacturer to fill all of your custom sheet metal parts for your production or business, then you come to the right place. Hengjin Hardware provides free technical assistance for your projects. When you contact us, you're assured of an experience that exceeds your expectations, you'll enjoy place of mind knowing that you found dedicate professionals.

We have our own equipments for a whole production flow, from mould design, prototypes develop, processing, assembly to surface coating. We have a high level team of engineers to provide you with the most practical and cost-effective solutions. Our workers are experienced and our quality control is strict. We have the ability to provide clients with high quality and low price products. Aligning ourselves with purchasers in the same vision of providing superior quality, has contributed to our success. Also honesty is our best policy. Our philosophy is simple: we deliver our promises.

If you are looking for a manufacturer to fill all of your custom sheet metal parts for your production or business, then you come to the right place. Hengjin Hardware provides free technical assistance for your projects. When you contact us, you're assured of an experience that exceeds your expectations, you'll enjoy place of mind knowing that you found dedicate professionals.

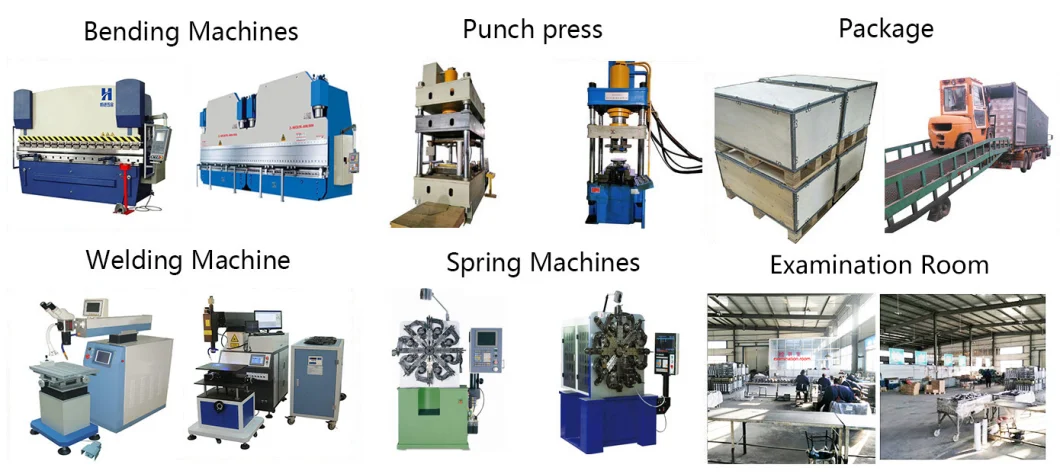

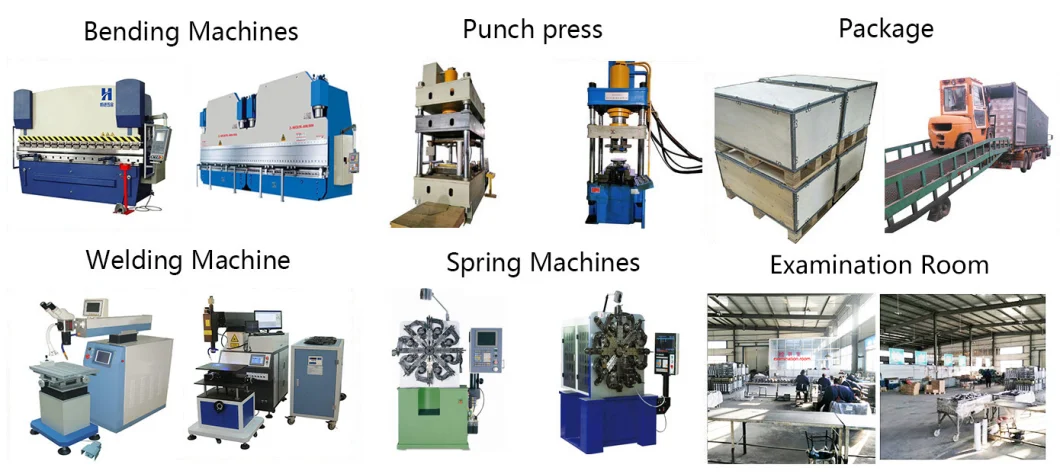

Machine list :

| Machine | Quantity | Parameter |

| Punch press | 30 | 25T-250T |

| Hydraulic press | 6 | 160T-315T |

| Cutter machines | 3 | CNC flame cutting machine, Air plasma cutting machine, Laser cutting machine |

| Shearing machines | 2 | 6*2500mm, 8*2500mm |

| Bending machines | 1 | 6*2500mm, 8*3200mm |

| All kinds of welding machines | 10 | Electric welding machine, Carbon dioxide protection welding machine, Argon arc welding machine, CNC automatic welding machine, Butt welding machine, Spot welding machines |

FAQ

Q: How soon can I get reply after send inquiry?

A:All inquiries will be replied within two hours except sleeping time in China.

Q: How soon can I get samples ?

A: The drawing determines the length of time,Generally samples can be sent out within 10 working days after product drawing confirmed by both side.

Q: What file format can you accept for my products?

A: 1.We can accept varies format, step, stp, jpg,pdf, dwg, dxf,3d and so on.

2.If you do not have a prepared CAD file, we can accept a scan of a hand drawn design.

Q: If I don't have drawing, how can I get sample ?

A: If you don't have any drawing,you can send us your sample, we will scan it and make 2D and 3D drawing first, then make sample for you.

Q: What are many common materials that you use in projects?

A: Aluminum,Stainless Steel, Carbon Steel, Copper, Plastics and so on.

Q: What's your MOQ(minimum order quantity?

A: Our MOQ is 100 pcs, you are welcome to send us trial order to test our quality and service.

Q: What's the payment term do you accept?

A: EXW/FOB Tianjin, paid by T/T, Western Union.