Basic Info.

Model NO.

HDC63-800

Working Voltage

220V+/-10%;,50Hz

Machine Weight

90kg-500kg

Oil Tank Capacity

3L

Maximum Working Pressure

6.3MPa

Total Area of Cylinder Piston

11.00cm2

Milling Power

1.5kw

Hydraulic Station Power

1.5kw

Transport Package

Fumigation-Free Wooden Case

Specification

Machine Weight: 90kg-154.8kg

Origin

China

HS Code

8468800000

Production Capacity

5000pieces/Year

Product Description

Economical automatic PE Pipe Fusion Butt Welding Machine

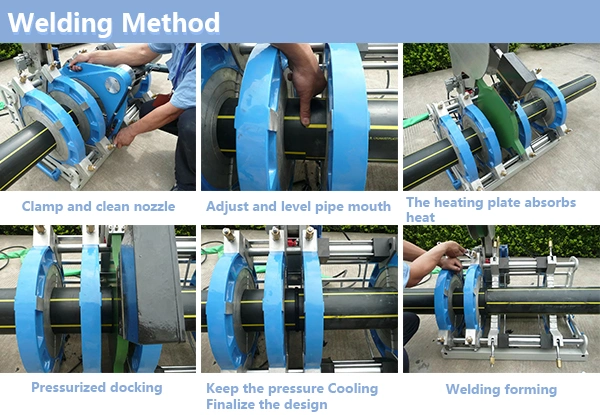

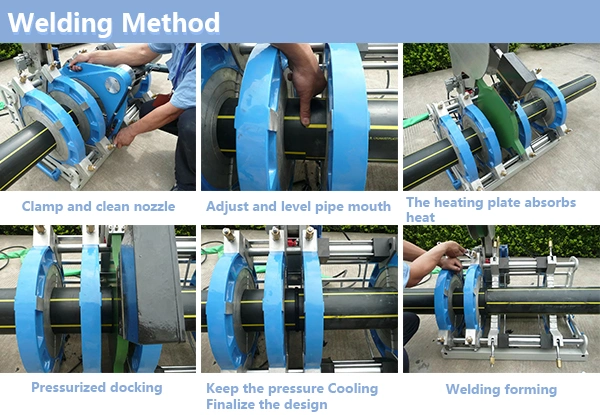

Pipe fusion butt welding machine is a kind of special welding equipment for welding thermoplastic pipe fittings with hot melt butt technology. The machine welding frame is separated from the operating system. The machine is composed of hydraulic operation console, welding frame and jig, electric heating plate, electric milling cutter and so on. The product is safe and reliable, light and easy to use.

Features:

Features:

The welding frame is made of high strength aluminum alloy, with firm structure, light and durable. The welding frame adopts the clamping mica sheet structure, the pipe positioning is accurate, and the unfitness of butt joint is easy to adjust. For the special specification of hot melt butt machine, we can design and manufacture according to the requirements of users.

Semi-automatic hot melt butt welder:

1. Building block frame structure, small mass, good rigidity;

2. Integrated hydraulic power unit, unique by-pass function, fast docking process, high pressure adjustment accuracy;

3. The clamp ADAPTS to a wide range of pipe diameter, and the structure is independent of each other, which can ensure the positioning accuracy without loss of pressure;

4. Semi-automatic hot plate is automatically drawn out to eliminate the influence of human factors;

5. Electronic temperature controller with high precision and small temperature gradient;

6. Can be welded all kinds of plastic joints, flanges and valves;

7. Can choose different computer control system upgrade to semi-automatic, automatic equipment;

8. The leakage protection function ensures the safety of the construction process.

Automatic hot melt butt welder:

1. The optimal welding parameters of pipes with different materials, caliber and SDR have been set in advance;

2. Automatic control of welding time, temperature and pressure;

3. Automatic detection and compensation of towing pressure;

4. The heating plate automatically pops up, and the temperature loss is reduced to the minimum;

5. In the welding process of each operation step of the implementation of the whole process of automatic monitoring and prompt;

6. The fast clamping system improves the working efficiency by 30%;

7. The dynamic data of welding process can be printed out, or downloaded to the PC of quality inspection personnel through the data transmission system, so as to review the performance of the welding machine and the operator;

8. The database can store up to 600 interface related welding parameters

Technical Parameters:

Application:

The fusion butt welders developed by our company are necessary supporting machines for pipeline construction. Our products are suitable for gas, water supply and drainage, chemical transportation and cable laying buried polyethylene pipe, polypropylene pipe and so on.

Special instructions:

3.1 The equipment is not suitable for connection or other operations between unspecified materials;

3.2 Do not use the device in an environment with explosion risk;

3.3 The operators of the equipment must be professionally trained;

3.4 The welder should be operated in a dry place. Protective measures should be taken when used on rainy days or wet ground.

3.5 The equipment uses 220V±10%, 50HZ voltage. If the use of power extension line, the extension line should have enough channel area.

Pipe fusion butt welding machine is a kind of special welding equipment for welding thermoplastic pipe fittings with hot melt butt technology. The machine welding frame is separated from the operating system. The machine is composed of hydraulic operation console, welding frame and jig, electric heating plate, electric milling cutter and so on. The product is safe and reliable, light and easy to use.

Features:

Features:The welding frame is made of high strength aluminum alloy, with firm structure, light and durable. The welding frame adopts the clamping mica sheet structure, the pipe positioning is accurate, and the unfitness of butt joint is easy to adjust. For the special specification of hot melt butt machine, we can design and manufacture according to the requirements of users.

Semi-automatic hot melt butt welder:

1. Building block frame structure, small mass, good rigidity;

2. Integrated hydraulic power unit, unique by-pass function, fast docking process, high pressure adjustment accuracy;

3. The clamp ADAPTS to a wide range of pipe diameter, and the structure is independent of each other, which can ensure the positioning accuracy without loss of pressure;

4. Semi-automatic hot plate is automatically drawn out to eliminate the influence of human factors;

5. Electronic temperature controller with high precision and small temperature gradient;

6. Can be welded all kinds of plastic joints, flanges and valves;

7. Can choose different computer control system upgrade to semi-automatic, automatic equipment;

8. The leakage protection function ensures the safety of the construction process.

Automatic hot melt butt welder:

1. The optimal welding parameters of pipes with different materials, caliber and SDR have been set in advance;

2. Automatic control of welding time, temperature and pressure;

3. Automatic detection and compensation of towing pressure;

4. The heating plate automatically pops up, and the temperature loss is reduced to the minimum;

5. In the welding process of each operation step of the implementation of the whole process of automatic monitoring and prompt;

6. The fast clamping system improves the working efficiency by 30%;

7. The dynamic data of welding process can be printed out, or downloaded to the PC of quality inspection personnel through the data transmission system, so as to review the performance of the welding machine and the operator;

8. The database can store up to 600 interface related welding parameters

Technical Parameters:

| Equipment Type | HDC63-160 | HDC63-200 | HDC90-250 | HDC160-315 | |

| Applied Materials | PE/PP/PVDF | ||||

| Applicable Diameter Range | 63-160mm | 63-200mm | 90-250mm | 160-315mm | |

| Applicable Ambient Temperature | -5~45ºC | ||||

| Working Voltage | 220V±10%,50HZ | ||||

| Total Power | 2.65kw | 3.25kw | 3.95kw | 4.95kw | |

| Including: Heating plate | 1kw | 1.6kw | 2kw | 3kw | |

| Milling Cutter | 0.9kw | 0.9kw | 1.2kw | 1.2kw | |

| Hydraulic Tank | 0.75kw | 0.75kw | 0.75kw | 0.75kw | |

| Insulation Resistance Of The Machine To The Ground | >1 MΩ | >1 MΩ | >1 MΩ | >1 MΩ | |

| Maximum Working Pressure | 6.3MPa | 6.3MPa | 6.3MPa | 6.3MPa | |

| Total Area Of Cylinder Piston | 11.00cm2 | 11.00cm2 | 11.00cm2 | 19.62cm2 | |

| Hydraulic Oil Type Used | Hydraulic Fluid No.46 | ||||

| Oil Tank Capacity | 3L | ||||

| Maximum Temperature Resistance Of Surface Coating | <270ºC | ||||

| Temperature Difference On Heating Plate Surface | ±5ºC | ||||

| Rack | Size(cm) | 82*44*40 | 85*48*44 | 85*53*43 | 94*62*60 |

| Weight(kg) | 38 | 42 | 52 | 80 | |

| Hydraulic Tank | Size(cm) | 58*47*47 | 58*47*47 | 58*47*47 | 58*47*47 |

| Weight(kg) | 41.5 | 41.5 | 41.5 | 41.5 | |

| Milling Cutter | Size(cm) | 31*24*32 | 35*36*35 | 36*47*47 | 59*38*58 |

| Weight(kg) | 6 | 7 | 17.5 | 22 | |

| Hot Plates | Size(cm) | 37*5*35 | 37*5*40 | 44*5.5*47 | 44*5*53 |

| Weight(kg) | 3 | 3.8 | 5.5 | 7.8 | |

| Basket | Size(cm) | 30*18.5*42 | 33.5*18.5*46 | 39*28*56.5 | 48*28.5*56.5 |

| Weight(kg) | 1.5 | 2.1 | 2.6 | 3.5 | |

| Machine Weight(kg) | 90 | 96.4 | 119.1 | 154.8 | |

Application:

The fusion butt welders developed by our company are necessary supporting machines for pipeline construction. Our products are suitable for gas, water supply and drainage, chemical transportation and cable laying buried polyethylene pipe, polypropylene pipe and so on.

Special instructions:

3.1 The equipment is not suitable for connection or other operations between unspecified materials;

3.2 Do not use the device in an environment with explosion risk;

3.3 The operators of the equipment must be professionally trained;

3.4 The welder should be operated in a dry place. Protective measures should be taken when used on rainy days or wet ground.

3.5 The equipment uses 220V±10%, 50HZ voltage. If the use of power extension line, the extension line should have enough channel area.