- Overview

- Product Description

- Our Advantages

- Product Parameters

- Detailed Photos

- Packaging & Shipping

- Company Profile

- Market and Customers

- FAQ

Basic Info.

Product Description

Automatic high speed high carbon wire drawing machine

(KY-LZ-560/7)

(1)Machine introduction

♦♦Hot Sale Straight Line Wire Drawing Machine

♦♦Wire drawing machine adopts PLC controller, it is easy to operate, one people can operate one production line. Wire drawing machine include water seal cooling system, so the temperature of the machine will not to high, it is safe to the worker. Wire drawing machine adopts frequency adjustable motor, the speed of the motor can be adjustable.

♦♦The high carbon wire straight line wire drawing machine is different from the ordinary wire drawing machine, it adopts AC frequency conversion control technology or DC programmable control system and screen display, with high degree of automation, convenient operation and high quality of drawing products. It is suitable for drawing various metal wires with diameter less than 12 mm.

(2)Main advantages

The main features of high carbon steel wire drawing machine are that the drum adopts narrow slot water cooling and the drawing die adopts direct water cooling; Good cooling effect; Gear box transmission is adopted, with high transmission efficiency and low noise; Fully enclosed protection system is adopted, with good safety; Air tension tuning is adopte.

Production Process:

High carbon wire raw material→ High pay-off frame/Hydraulic wire pay off→ Shelling and Rust removal →Wire rod sand belt polishing machine→ Online boron coating and drying machine →LZ7/560 straight line Wire Drawing Machine→Tension device → Wire take-up machine

Main functions:

(1)Accurate meter counting with an error of 0.1%;

(2)Fixed length automatic deceleration and stop;

(3)Disconnection detection and automatic shutdown;

(4)Positive and negative inching and left-right linkage of any drum;

(5)Display of various fault information and processing information;

(6)Various motion information monitoring.

| Model | LZ400 | LZ560 | LZ600 | LZ800 |

| Capstan diameter | 400mm | 560mm | 600mm | 800mm |

| Drawing dies | 9 | 9 | 9 | 9 |

| Inlet wire diameter | Φ2.5-4.5 mm | Φ5.5-6.5 mm | Φ6.5-8.0 mm | Φ8.0-10.0 mm |

| Outlet wire diameter | Φ0.8-1.4 mm | Φ1.6-2.0 mm | Φ2.0-3.0 mm | Φ2.8-3.5 mm |

| Drawing speed | 10-16 m/s | 8-12 m/s | 6-12 m/s | 6-10 m/s |

| Total reduction rate | 90.32% | 90.53% | 90.53% | 90.53% |

| Motor power | 11-15 kw | 30-37 kw | 30-37 kw | 37-75 kw |

| (1)Wire Pay off system Wire pay off system usually is pneumatic lifting pulley, convenient wire threading. Customers can choose hydraulic wire pay off systems or ordinary wire pay off systems. | (2)Control cabinet High degree of mechanical automation, all kinds of fault information and processing information are displayed on the screen. |

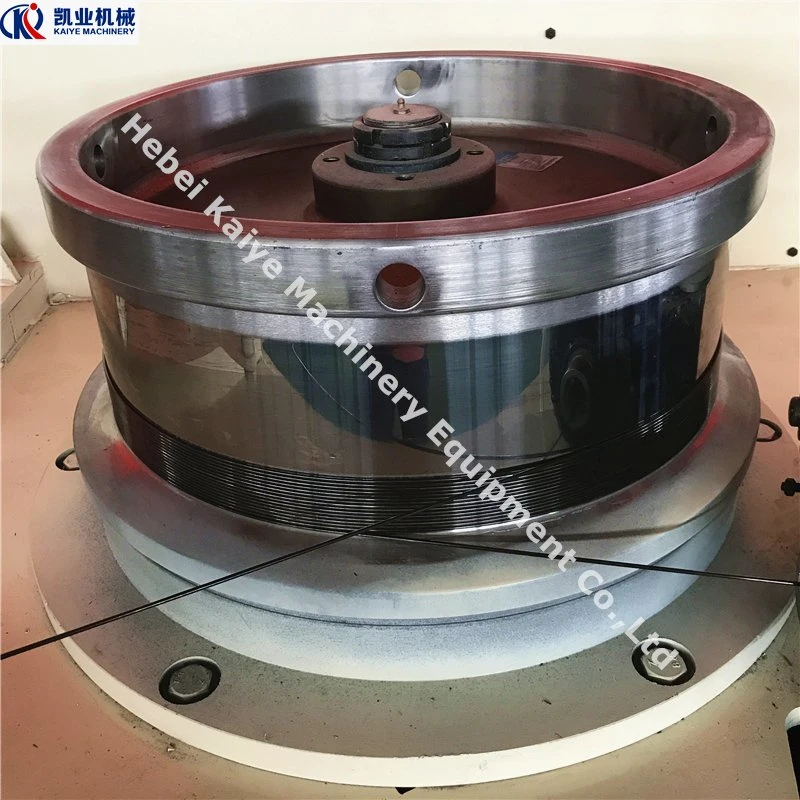

| (3)Capstan Capstan uses special materials to spray tungsten carbide on the surface and increase the height and thickness. The drum base adopts narrow slot design to effectively prevent rust and impurities from entering the drum. | (4)Rotary die box The whole set of machinery uses a rotating die box, which can make it easier for the wire drawing powder to adhere to the surface of the wire rod. Improve the quality of wire rod finished products. |

| (5)Gear box The mechanical transmission system adopts the direct connection between the gearbox and the motor, which can greatly reduce the noise, improve the reliability of operation and increase the transmission power. Save electricity. | (6)Inverter The machine is equipped with frequency converter, and the energy-saving effect is very obvious. It is very convenient to adjust the speed. The frequency converter also has many protection functions, such as overcurrent, overvoltage, overload protection and so on. |

The main machinery is packed with plastic film and fixed in the container with steel wire. Small mechanical parts are packed in wooden cases.

Shipment:

We can book containers for customers according to the mechanical size. If we need LCL, we can arrange to pack and send them to the designated place.

| No. | Name | Quantity | Notes |

| 1 | High pay-off frame | 1 set | we can also produce hydraulic wire pay off systems |

| 2 | Derusting machine | 1 set | |

| 3 | Straight Line Wire Drawing Machine | 1 set | The number of drawing drums need to be confirmed. |

| 4 | Wire take-up system | 1 set | Elephant trunk wire take-up system or Spool wire take-up system |

| 5 | Pointing Machine | 1 set | Accessory Equipment |

| 6 | Butt-Welding Machine | 1 set | Accessory Equipment |

| 7 | Wire rod sand belt polishing machine | 1 set | Accessory Equipment |

| 8 | Online boron coating and drying machine | 1 set | Accessory Equipment |

| For more details , you can contact me at any time. | |||

We have our own wire mesh machinery and several pilot plants with strong technical force and advanced production and checkout equipment.

Our main products: straight line wire drawing machine,Pulley wire drawing machine,wet drawing machine,Copper wire drawing machine,Stainless steel wire drawing machine, Galvanized wire production line,Wire winding machine,And other wire drawing supporting machinery and accessories.

Factory History:

Hebei Kaiye Machinery Equipment Co., Ltd., founded in 2002, is famous as "Hometown of wire mesh" in China. We are a professional manufacturer of wire mesh machinery.

Our company has been developing smoothly and quickly and now we have more than 150 employees.We can provide high quality machinery and excellent service.

Factory Customer and Friends from all over the world

Kaiye's quality has been managed by the standard of ISO9001 International Quality Management System. We have built good reputation among our customers with excellent quality products, reliable services and credit. We have been supplying the domestic market and also have exported to the Romania, Turkey, Poland, Ukraine, Russia, Kazakhstan, Saudi Arabia, Vietnam, Philippines, India, Thailand, South Africa, Algeria, Australia, Mexico, Colombia, Argentina, Bolivia and Brazil.

After more than ten years of development, the company has grown into one of the leading enterprises in the industry. We adhere to the tenet of "customer first, technology leading". In the future, the company will comprehensively promote industrial development and upgrading, and build the world's leading steel processing equipment.

»Product Application

The Straight line wire drawing machine is the important process of producing the steel wire.

Such as:

•High carbon steel wire (PC wire, wire rope, spring wire, steel cord, hose wire, bead wire, saw wire )

•Low carbon steel wire (Mesh, fence, nail, steel fiber, welding wire, construction)

•Alloy wire

Q: Are you a manufacturer?

A: Yes, we have been in providing the professional products more than 18 years.

Q: How about the delivery?

A: We promise that we provide wire machine, mold, brushed powder machine test operation service in the workshop, and then delivery.

Q: What is the shipping method?

A: 1)Shipping method:Land carriage, sea transport.

2)Our service: FOB, CIF, C&F, Door to Door, etc.

3)We usually choose the most economical and reliable shipping company to make sure you receive the goods in time.

Q: How do you guarantee your machine's quality when producing?

A: Our services are always by your side, We have our technicians to inspect the parts of the machine every day, the machine will be adjusted well in our factory before shipment ,all the parts are in good condition.

Hello my friend,

I' m appreciated that you're interested in our wire drawing machines.

If you are interested in anyone above wire drawing machines,please contact us now. I am happy to reply you.

Note:

Please provide following information if you want the directly quotation:

1. Wire Material:Please provide following information if you want the directly quotation:

2. Inlet Wire Diameter range:

3. Outlet wire Diameter range:

4. Where and what does the wire use for: