Basic Info.

Model NO.

HB

Feature

Rust / Corrosion Proof

Condition

New

Customized

Customized

Running Speed

8-15min Per Bacth

Blast Wheel

2-5 Wheels or Customized

Control Type

PLC Full Automatic Control

Color

Customers Requirement

Surface Finish Level

SA2.5 to SA3.0

Dust Collector

Cartridge/Bag Type Filter Pulse Reverse

Cleaning Material

Shot Steel/Shot Grit/Wire Cut etc

After-Sales Service

Field Installation, Commissioning and Training

Noise

Less Than 85dB

Electricity Key Parts

Omron,Siemens,Chint

Cleaning Method

Automatic

Transport Package

20FT/40FT Container

Specification

HB

Trademark

ET

Origin

Qingdao, China

HS Code

8460909000

Production Capacity

30sets/Month

Product Description

1. Description

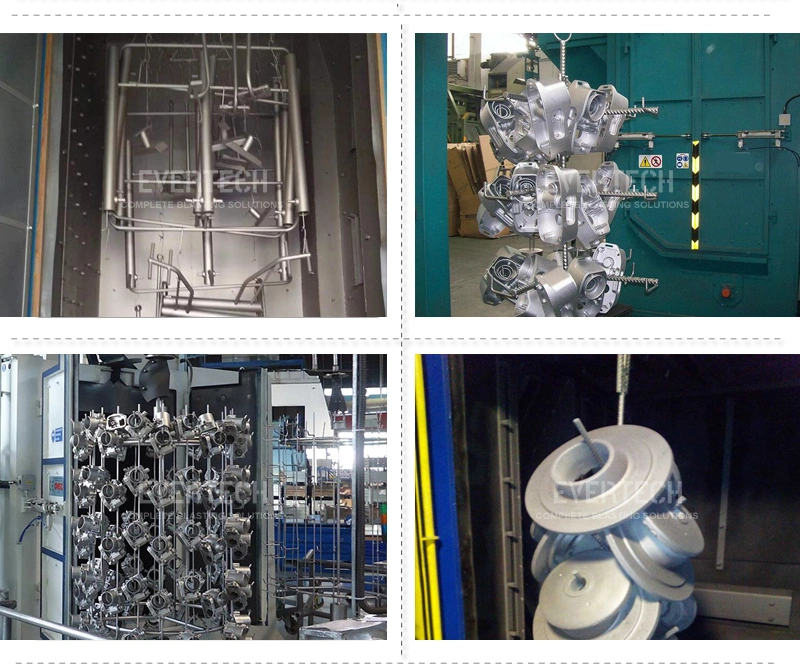

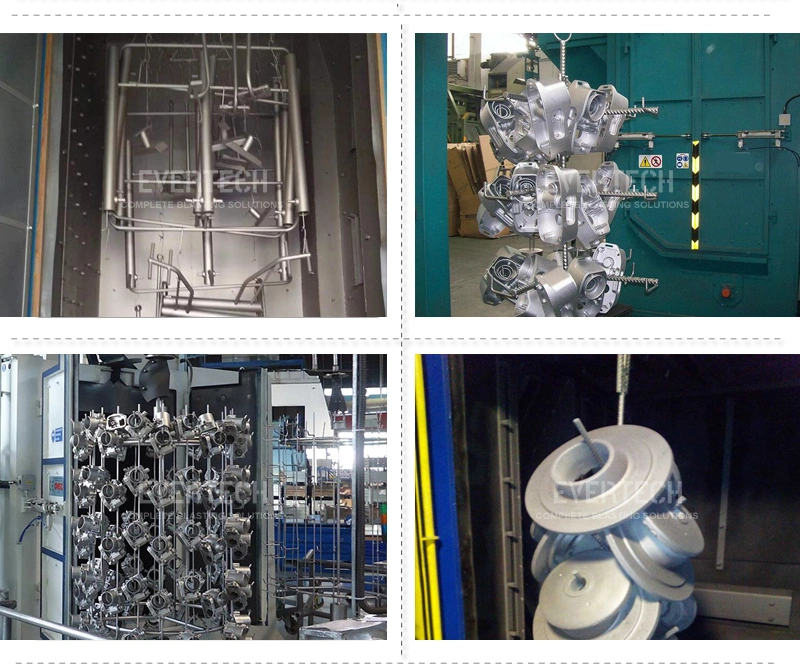

Spinner Hanger Shot Blast Machine is a good ideal to treat parts of small sizes and particularly fragile parts.

It installations with operational flexibility, suitable for many types of work, it is the most suitable machine for any need.

The hook runs and rotates inside the machine exposing all the surface of the work pieces to the abrasive action from the wheels, positioned on the side of the blast chamber.

2. Features

• Exhaust system: Compact with cartridges made from non-woven filtering media. The cleaning is done automatically by means of reverse pulse jet. The residual dust level is about 3mg/m³ without the after filter, which fulfills most international norms.

• Blast wheels: with exclusive wider blasting pattern , see side drawing, which reduces drastically the required blasting cycle time when compared with the conventional spinner hangers without oscillation system and with some production gains even when compared with the spinner hangers equipped with oscillation system.

• Work doors: Two with manual opening, built from a welded structure that is mounted over bearings. Equipped with labyrinth type sealing and safety lock that does not allow the opening while blasting.

• Control panel: Mounted in a armored enclosure, fulfills the international norms and is equipped with blast wheel amperage meters and friendly interface for equipment operation.

• Optionals: Frequency inverter for the blast wheels, rotating screen or vibratory screen and high chrome alloy steel liners for steel grit abrasive media.

3. Technical Parameter

My friend, if you are interested in our products, our company and factory, you can contact us right at now! our beautiful good

salesman will give you the most sincere service and the most satisfactory answer!

Spinner Hanger Shot Blast Machine is a good ideal to treat parts of small sizes and particularly fragile parts.

It installations with operational flexibility, suitable for many types of work, it is the most suitable machine for any need.

The hook runs and rotates inside the machine exposing all the surface of the work pieces to the abrasive action from the wheels, positioned on the side of the blast chamber.

2. Features

• Exhaust system: Compact with cartridges made from non-woven filtering media. The cleaning is done automatically by means of reverse pulse jet. The residual dust level is about 3mg/m³ without the after filter, which fulfills most international norms.

• Blast wheels: with exclusive wider blasting pattern , see side drawing, which reduces drastically the required blasting cycle time when compared with the conventional spinner hangers without oscillation system and with some production gains even when compared with the spinner hangers equipped with oscillation system.

• Work doors: Two with manual opening, built from a welded structure that is mounted over bearings. Equipped with labyrinth type sealing and safety lock that does not allow the opening while blasting.

• Control panel: Mounted in a armored enclosure, fulfills the international norms and is equipped with blast wheel amperage meters and friendly interface for equipment operation.

• Optionals: Frequency inverter for the blast wheels, rotating screen or vibratory screen and high chrome alloy steel liners for steel grit abrasive media.

3. Technical Parameter

Type | HB 7/12 | HB 10/16 | HB 12/18 | HB 14/22 | HB 16/23 | HB 18/25 | HB 30/30 |

Max. diameter of workpiece (mm) | 700 | 1000 | 1200 | 1400 | 1600 | 1800 | 3000 |

Max. height of workpiece (mm) | 1200 | 1600 | 1800 | 2200 | 2300 | 2500 | 3000 |

Max. weight of workpiece (kg) | 500 | 800 | 1000 | 2000 | 3000 | 5000 | 10000 |

Number of wheels | 2 | 2 | 2 | 3 | 3 | 4 | 5 |

Power per blast wheel (kW) | 7.5 | 7.5/11 | 11/15 | 7.5/11/15 | 7.5/11/15 | 7.5/11/15 | 7.5/11/15 |

Frequently Asked Questions

Q1: How do I get the best price?

A: As you may know, the different type of blasting machine apply to the different price.

Q2: What machine suits me best?

A: Different workpieces and the different model apply to the different machine.

Please tell us what's kind of workpieces need to blast cleaning?

And what's MAX size of the workpieces ?

Then we will recommand the most suitable model and the best price for you.

Q3: In case of failure,how to do?

A: Call us----our enginners are online for 24-hours,and ready to serve you.

Replacement of damaged parts for free---For more information,please contact us

Q4: Are you trading company or manufacturer ?

A: We are factory.

Q5: How long is your delivery time?

A: Generally it is a week days if the goods are in stock. or it is 15 working days if the goods are not in stock, it is according to quantity.

Q6: How many people are needed to run the Evertech's shot blasting machine?

A: For Evertech's standard blasting unit, one people will be enough. But for the custom complex production line integrated with shot blaster, the number of operators is varied according to the other accessory equipment and the whole line automaticity.

Q7: What does it cost to operate?

A: The highly efficient turbines require much less power that competitor's shot blast machines. Including abrasive consumption, power consumption and maintenance, the total operating cost averages from $5- $20 per hour. When comparing this to your current methods, keep in mind that the auto shot blasting machine is at least 4 to 5 times as productive as manual cleaning and only one operator is required to load and run the machine while it is working. Labor costs are much lower, plus you will have a huge amount of extra capacity for cleaning.

Q8: What utilities are needed to run the blasting machine?

A: The electrical system runs on three-phase input and a transformer will be provided for your supply voltage if required. Clean and dry compressed air supply is also needed.

A: As you may know, the different type of blasting machine apply to the different price.

Q2: What machine suits me best?

A: Different workpieces and the different model apply to the different machine.

Please tell us what's kind of workpieces need to blast cleaning?

And what's MAX size of the workpieces ?

Then we will recommand the most suitable model and the best price for you.

Q3: In case of failure,how to do?

A: Call us----our enginners are online for 24-hours,and ready to serve you.

Replacement of damaged parts for free---For more information,please contact us

Q4: Are you trading company or manufacturer ?

A: We are factory.

Q5: How long is your delivery time?

A: Generally it is a week days if the goods are in stock. or it is 15 working days if the goods are not in stock, it is according to quantity.

Q6: How many people are needed to run the Evertech's shot blasting machine?

A: For Evertech's standard blasting unit, one people will be enough. But for the custom complex production line integrated with shot blaster, the number of operators is varied according to the other accessory equipment and the whole line automaticity.

Q7: What does it cost to operate?

A: The highly efficient turbines require much less power that competitor's shot blast machines. Including abrasive consumption, power consumption and maintenance, the total operating cost averages from $5- $20 per hour. When comparing this to your current methods, keep in mind that the auto shot blasting machine is at least 4 to 5 times as productive as manual cleaning and only one operator is required to load and run the machine while it is working. Labor costs are much lower, plus you will have a huge amount of extra capacity for cleaning.

Q8: What utilities are needed to run the blasting machine?

A: The electrical system runs on three-phase input and a transformer will be provided for your supply voltage if required. Clean and dry compressed air supply is also needed.

Contact With US

My friend, if you are interested in our products, our company and factory, you can contact us right at now! our beautiful good

salesman will give you the most sincere service and the most satisfactory answer!

Looking forward to your consultations!