Basic Info.

HS Code

8515190090

Production Capacity

50

Product Description

Product description

It can be applied to brazing and bright heat treatment of stainless steel, carbon steel, brass, copper, ceramics and other parts.

Brazing Features:

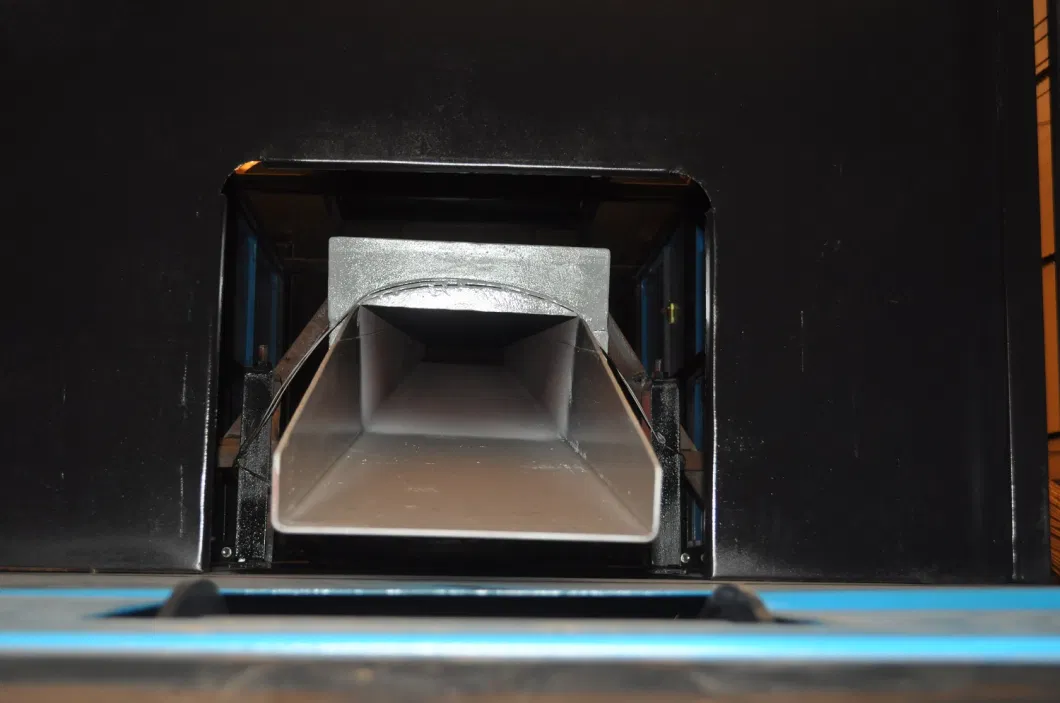

• The latest design of the muffle in the heating furnace has obtained a national patent. Its material is made of heat-resistant stainless steel containing rare earth elements from Sweden, which has good structural strength, small thermal deformation, and improved service life. Under normal working conditions (furnace temperature 1120 ºC) ), its service life can reach more than 1.5 years; when the furnace temperature is below 950 ºC, its service life can be more than 3 years.

• The cooling section adopts the welding seam separation technology of the cooling inner muffle and the cooling water jacket, which ensures that the brazed workpiece is bright and free of oxidation. The invention patent is being approved by the state.

• The cooling section is equipped with a heat exchanger, which greatly improves the cooling rate of the workpiece.

• Use imported furnace lining materials to reduce energy consumption.

• The special design enables parameter adjustment in each area of the heating zone to ensure the stability of the furnace temperature of the heating furnace. The furnace temperature control accuracy can reach ±1ºC.

• Unique explosion-proof design, using a variety of alarms and circuit interlocking automatic protection devices to ensure the safe operation of the furnace.

| Model | Total length of furnace body (m) | Rated power (kw) | Number of heating zones | Furnace size (L.W.H-mm) | Effective cooling length(mm) | heating time(h) | Power loss of empty furnace(kw) | output(kg/h) | power(kw) | Decomposition ability(m³/h) |

| Rc18-30 | 18 | 100 | 4 | 4000 300 150 | 10000 | ≤4 | 15 | 100 | 23 | 15 |

| Rc20-35 | 20 | 120 | 5 | 4500 320 180 | 11000 | ≤4.5 | 18 | 120 | 32 | 20 |

| Rc20-50 | 20 | 130 | 5 | 4500 350 200 | 11000 | ≤5 | 20 | 140 | 46 | 30 |

| Rc28-60 | 28 | 160 | 7 | 5000 400 250 | 13000 | ≤6 | 25 | 180 | 46 | 35 |

Company introduction

APS Induction Technology (Taizhou) Co., Ltd. is a rare high-tech enterprise in China with international leading technology in induction melting and heating field. At present, the capacity of induction melting furnaces produced can up to 70 tons, and the power supply can reach to 50,000kw. The heating equipment can be used in carbon-based/ceramic-based composite materials, carbon fiber/silicon carbide fiber, high-performance ceramics, graphite, vacuum diffusion welding, vacuum hot pressing, vacuum melting, powder metallurgy, environmental protection and other industrial.

In addition, we are also a professional manufacturer of power control boards, induction coils, water-cooled cables, yokes, and reactors. Compared with other manufacturers in China, we have outstanding advantages in product price, quality control, and delivery time.

As an industrial equipment manufacturer with R & D capabilities, we keep seeking a balance between product economy and practicability in continuous innovation to ensure that we can provide the most valuable production solutions for each application, reduce costs for our users and help them improve production competitiveness.

We hope to establish a more efficient, clean, low-carbon and circular green casting system by supplying stable, high-efficiency, energy-saving, safe and relatively cheap induction melting and heating equipment, and contribute to global energy conservation and emission reduction.

|  |  |