Basic Info.

Model NO.

2in1

Voltage

380V

Automatic Grade

Automatic

Principle

Small Deformation

Certification

CE

Warranty

24 Months

Customized

Customized

Condition

New

Color

Customizable

Dimension

as Model

Applicable Industries

Building Material Shops, Printing Shops, Construct

Weight

as Model

Machinery Test Report

Provided

Core Components

PLC, Engine, Bearing, Motor, Pressure Vessel, Gear

Key Selling Points

Easy to Operate

Function

Decoiler, Uncoil, Straightener, Straightening

After Warranty Service

Video Technical Support, Online Support

Product Name

2 in 1 Decoiling Straightening Machine

Material Processing

Aluminum, Carbon Steel, Stainless Steel

Automatic

Automatic

Power

as Type

Local Service Location

Canada, Turkey, United Kingdom, France, Viet Nam

Fter-Sales Service Provided

Free Spare Parts, Field Installation, Commissionin

Transport Package

Standard Export Package

Specification

Maximun width(mm):150,200,300,400,500,600,700,800,

Trademark

BESCOMT

Origin

Shandong

Production Capacity

100+

Packaging & Delivery

Package Size

589.80cm * 235.20cm * 238.50cm

Package Gross Weight

10000.000kg

Product Description

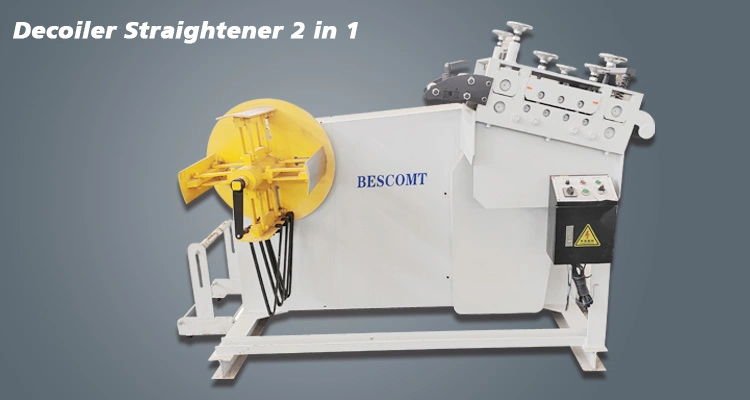

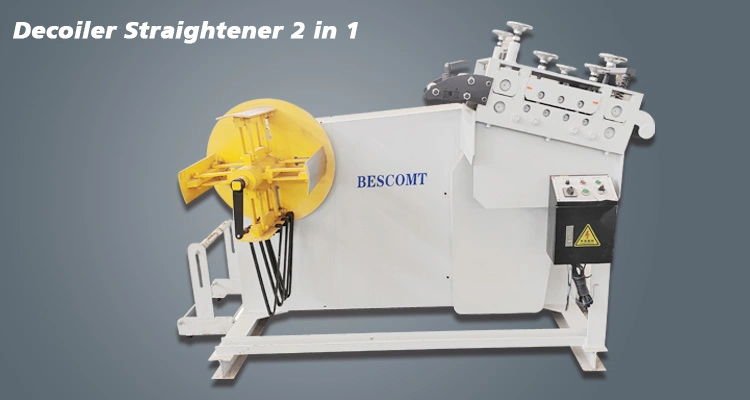

2in1 Decoiler Straightener for servo feeder

Decoiler and straightener 2 in 1 machine is widely used in stamping and cutting of hardware, stamping, electronics, electrical appliances, science and technology, auto parts, metal, packaging, industry, precision, aviation, cabinets, automotive, science and technology, machinery, electrical, mechanical and other industries.

| | GO-150 | GO-200 | GO-300 | GO-400 | GO-500 | GO-600 | GO-700 |

| Material width(mm) | 150 | 200 | 300 | 400 | 500 | 600 | 700 |

| Material thickness(mm) | 0.35-3.2 | 0.35-3.2 | 0.35-3.2 | 0.35-3.2 | 0.35-3.2 | 0.35-3.2 | 0.35-3.2 |

| Material I.D(mm) | 450-530 | 450-530 | 450-530 | 450-530 | 450-530 | 450-530 | 450-530 |

| Material O.D(mm) | 1200 | 1200 | 1200 | 1200 | 1200 | 1200 | 1200 |

| Material weight(kgs) | 2000 | 2000 | 2000 | 3000 | 3000 | 4000 | 4000 |

| Machine weight(kgs) | 800 | 900 | 900 | 1100 | 1200 | 1200 | 1400 |

Metal sheets stamping line configuration

Metal sheet stamping line is widely used to LED parts, automobile stamping, appliances manufacturing, computer and electronic componets, hardware and metal parts etc industry.

The configuration of NC Servo metal Punch Press Feeder Stamping line

Step-1: Decoiler Straightener machine, Loading coil and uncoilling coil and straigthening the Coil strips.

Step-2: NC Servo Roll Feeder machine, Feed coil strips to press machine.

Step-3: Power pres machine with the moulds,pressing to the end product

Step-1: Decoiler Straightener machine, Loading coil and uncoilling coil and straigthening the Coil strips.

Step-2: NC Servo Roll Feeder machine, Feed coil strips to press machine.

Step-3: Power pres machine with the moulds,pressing to the end product

1.We provide 24 hours on-line service and overseas after-sales

Can contact us by MSN, Skype, Email and Telephone at any timeOur factory also will make DVD to show the operation steps for the customer.2.We can send the component by DHL, TNT freely

Our guarantee time is two years, if any component is damaged during guarantee time

3.Our factory can send our engineer to the customer's factory install, commission and training freely

3.Our factory can send our engineer to the customer's factory install, commission and training freely

The customer provide the double trip tickets, food and accommodation for our engineer. The customer also can send the engineer to our factory to learn the operation and maintains freely.

1.Can you supply the relevant documentation?

Yes, we can provide most documentation including Certificates of Analysis /Conformance; Insurance; Origin, and other export documents where required.

2.What kinds of payment methods do you accept?

You can make the payment to our bank account, Western Union or PayPal:30% deposit in advance, 70% balance before delivery

3.Guaranty covers?

Main parts of the machine , wearing parts not included .PARTS DELIVERY. Within 5 days by DHL / Fexed .

4.About our after-sale service:

Customer service 24 hours online, you can send technicians to your country to repair the machine. Buyer shall bear all costs including visa, round trip airfare and suitable accommodation and buyer shall pay usd 100 / day salary.

5.How to replace machine parts?

Parts adopt international brands, good quality, no need to replace within 3-5 years, convenient to buy suitable parts locally.

6.Installation&Commissioning:

Usually solved by video conference, if necessary, can be dispatched to the door installation debugging and maintenance of technical personnel.

Yes, we can provide most documentation including Certificates of Analysis /Conformance; Insurance; Origin, and other export documents where required.

2.What kinds of payment methods do you accept?

You can make the payment to our bank account, Western Union or PayPal:30% deposit in advance, 70% balance before delivery

3.Guaranty covers?

Main parts of the machine , wearing parts not included .PARTS DELIVERY. Within 5 days by DHL / Fexed .

4.About our after-sale service:

Customer service 24 hours online, you can send technicians to your country to repair the machine. Buyer shall bear all costs including visa, round trip airfare and suitable accommodation and buyer shall pay usd 100 / day salary.

5.How to replace machine parts?

Parts adopt international brands, good quality, no need to replace within 3-5 years, convenient to buy suitable parts locally.

6.Installation&Commissioning:

Usually solved by video conference, if necessary, can be dispatched to the door installation debugging and maintenance of technical personnel.