Basic Info.

Model NO.

STZ-8-12

Working Temperature

1150c

Chamber Size

200mm(W)X 300mm(L)X 120mm(H)

Heating Rate

10-30c/Min

Voltage

AC 220V, Single Phase, 50/60 Hz

Power

3kw

Heating Element

High Temperaturee Alloy Wire

Vacuum Level

-0.098MPa

Control Mode

SCR Control, Pid Parameter Self-Setting

Thermocouple

S-Type

Transport Package

in Plywood Case

Specification

CE/ISO9001 certificate

Trademark

Sante

Origin

China

HS Code

8514

Production Capacity

50sets/Month

Product Description

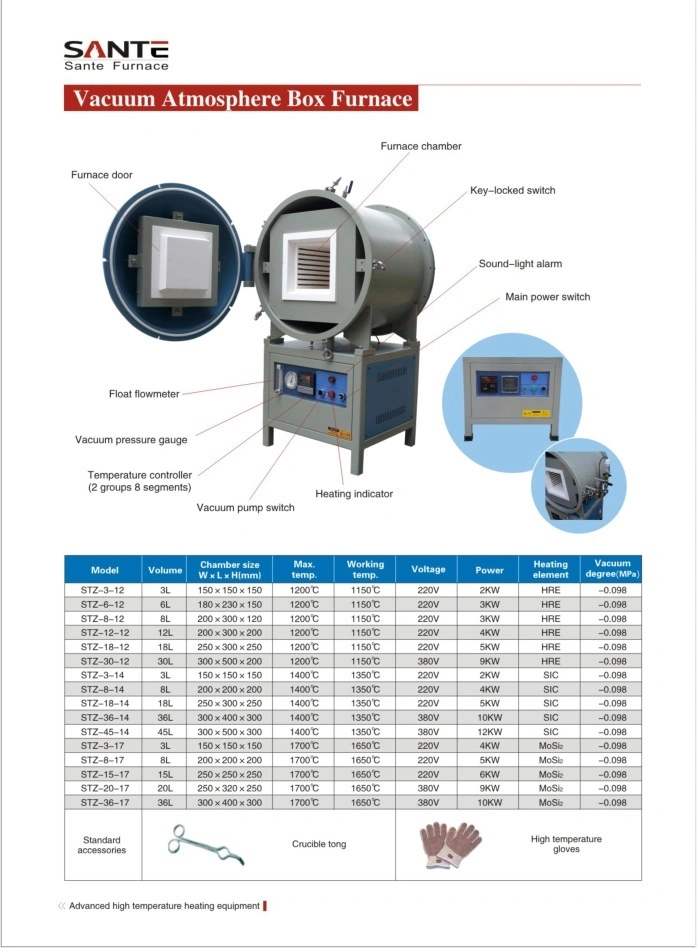

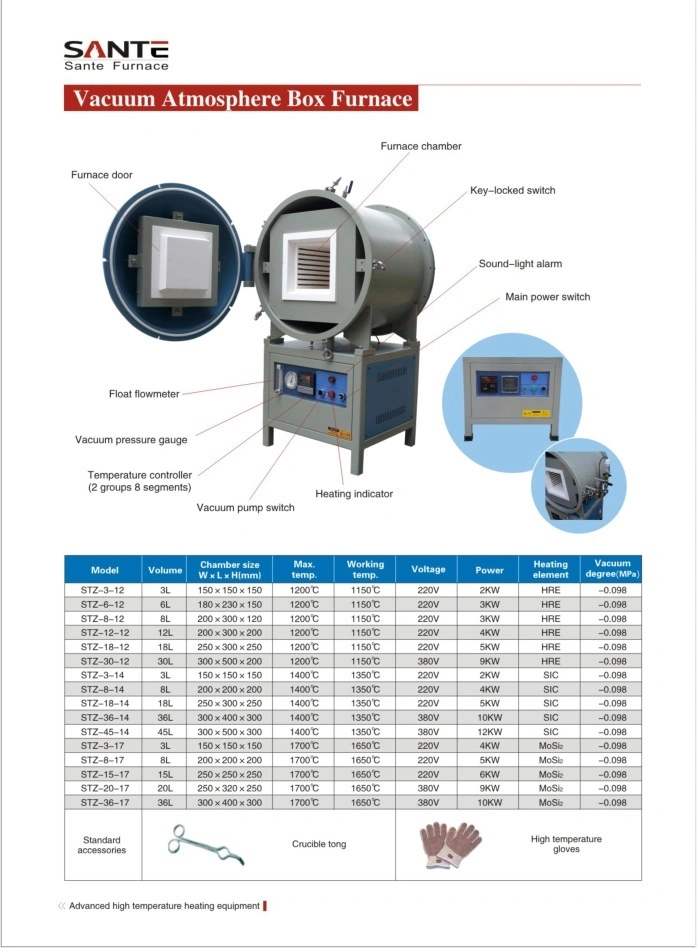

(200*300*120mm)1200c High Temperature Vacuum Electric Muffle Furnaces for Thermal Treatments

Product features:

1. Chamber material adopts vacuum forming ceramic fiber.It has not powder drops off with high temperature , small heating capacity and saving energy more than 50%.

2.Heating element adopts high temperature alloy wire,which can bear heavy load. It is stable and has long service life

3. High heating speed,and it takes 15-30 minutes from room temperature to 1000ºC

4. High precision of temperature control with the temperature compensation and correction function at precision ±1ºC

5. Imported temperature control instrument with the programmable function can set heating curve and programme 2 groups 16 segments.

6.Integrative structure can reduce the used space with excellent appearance design.

7. Electronic parts and components adopt DELIXI brand with earth leakage function .It is safe and reliable.

8. With alerting signal for the over-temperature during the working process,which can complete protective action automatically.

9.When the programs are set and press the starting button , the following steps will proceed automatically.

10.Double door design structure with flange sealing and PTFE sealing ring can insure sealing property and can inlet inert protective gas under vacuum .The external metal pipe can make the high temperature volatile hazardous gases flow to the specified place.

11.Optional large screen paperless recorder is available which can complete the real time record of the heating curve.It can analysis and print experimental data with memory card .

Specifications:

Models:

Product pictures:

Packaging & Shipping:

1) Packing: from the inside to outer packaging, is foam sponge, carton, wooden case.

2) Transport modes: Sea or Air transportation, TNT, DHL express or FedEx.

3) Please make sure the 'shipping address' is your confirmed address.

4) We do check everything in good condition before we ship your parcel out.

5) We will process your order ASAP after payment is confirmed.

About us:

1. We are a leading and professional enterprise that specializes in the manufacture of high temperature muffle Furnaces

2. Our products have a number of technical patents and have passed the ISO9001 quality system certification and CE certificate.

3. Our products covers 1000/1200/1300/1400/1600/1700ºC muffle furnace, tube furnace, vacuum box furnace, dual(multi) zone tube furnace, industrial furnace, elevator/bottom loading muffle furnace, car-type bottom furnace, etc.

4. After ten years development, with scientific and strict management system and first-class technology strength, Sante furnace has provided lots of muffle furnaces for colleges and universities, research institutes, petrochemical plants, petroleum, smelting, casting, machinery manufacturing, military industry and other industries in China and overseas.

Product features:

1. Chamber material adopts vacuum forming ceramic fiber.It has not powder drops off with high temperature , small heating capacity and saving energy more than 50%.

2.Heating element adopts high temperature alloy wire,which can bear heavy load. It is stable and has long service life

3. High heating speed,and it takes 15-30 minutes from room temperature to 1000ºC

4. High precision of temperature control with the temperature compensation and correction function at precision ±1ºC

5. Imported temperature control instrument with the programmable function can set heating curve and programme 2 groups 16 segments.

6.Integrative structure can reduce the used space with excellent appearance design.

7. Electronic parts and components adopt DELIXI brand with earth leakage function .It is safe and reliable.

8. With alerting signal for the over-temperature during the working process,which can complete protective action automatically.

9.When the programs are set and press the starting button , the following steps will proceed automatically.

10.Double door design structure with flange sealing and PTFE sealing ring can insure sealing property and can inlet inert protective gas under vacuum .The external metal pipe can make the high temperature volatile hazardous gases flow to the specified place.

11.Optional large screen paperless recorder is available which can complete the real time record of the heating curve.It can analysis and print experimental data with memory card .

Specifications:

| Maximum temperature | 1200ºC(for short time) |

| Working temperature | 1150ºC (continuous) |

| Heating rate | 10-30ºC/min, it will take 15-30minutes from room temperature to 1000ºC |

Chamber size | Chamber size:200*300*120(W*L*H) |

| Temperature control | 16 steps programmable and PID automatic control |

Voltage | AC220V single Phase,50/60 Hz |

Power | 3KW |

| Heating element | Resistance wires |

| Thermocouple | S-type |

| Furnace atmosphere | Nitrogen, Argon and other inert gases |

| Vacuum value | -0.098MPa |

Standard accessories | High temperature gloves 1 pair, crucible tong 1pc, Al2O3 sample block 1pc,power line 1 pc |

| Warranty | One year limited warranty (Consumable parts such as processing tubes, o-rings and heating elements are not covered by the warranty.) |

| Model | Volume | Chamber size (W×L×H:mm) | Max. temperature | Working temperature | Heating element | Temp. precision | Vacuum degree | Voltage | Power |

| STZ-3-12 | 3L | 150x150x150 | 1200ºC | 1150ºC | Resistance wire | ±1ºC | -0.098 Mpa | 220V | 2KW |

| STZ-6-12 | 6L | 180x230x150 | 220V | 3KW | |||||

| STZ-8-12 | 8L | 200x300x120 | 220V | 3KW | |||||

| STZ-18-12 | 18L | 250x300x250 | 220V | 5KW | |||||

| STZ-30-12 | 30L | 300x500x200 | 380V | 9KW | |||||

| STZ-3-14 | 3L | 150x150x150 | 1400ºC | 1300ºC | SiC rod | ±1ºC | -0.098 Mpa | 220V | 2KW |

| STZ-8-14 | 8L | 200x200x200 | 220V | 4KW | |||||

| STZ-18-14 | 18L | 250x300x250 | 220V | 5KW | |||||

| STZ-36-14 | 36L | 300x400x300 | 380V | 10KW | |||||

| STZ-45-14 | 45L | 300x500x300 | 380V | 12KW | |||||

| STZ-3-17 | 3L | 150x150x150 | 1700ºC | 1600ºC | MoSi2 rod | ±1ºC | -0.098 Mpa | 380V/220V | 4KW |

| STZ-8-17 | 8L | 200x200x200 | 380V/220V | 5KW | |||||

| STZ-15-17 | 15L | 250x250x250 | 380V/220V | 6KW | |||||

| STZ-20-17 | 20L | 250x320x250 | 380V | 8KW | |||||

| STZ-36-17 | 36L | 300x400x300 | 380V | 10KW |

Packaging & Shipping:

1) Packing: from the inside to outer packaging, is foam sponge, carton, wooden case.

2) Transport modes: Sea or Air transportation, TNT, DHL express or FedEx.

3) Please make sure the 'shipping address' is your confirmed address.

4) We do check everything in good condition before we ship your parcel out.

5) We will process your order ASAP after payment is confirmed.

About us:

1. We are a leading and professional enterprise that specializes in the manufacture of high temperature muffle Furnaces

2. Our products have a number of technical patents and have passed the ISO9001 quality system certification and CE certificate.

3. Our products covers 1000/1200/1300/1400/1600/1700ºC muffle furnace, tube furnace, vacuum box furnace, dual(multi) zone tube furnace, industrial furnace, elevator/bottom loading muffle furnace, car-type bottom furnace, etc.

4. After ten years development, with scientific and strict management system and first-class technology strength, Sante furnace has provided lots of muffle furnaces for colleges and universities, research institutes, petrochemical plants, petroleum, smelting, casting, machinery manufacturing, military industry and other industries in China and overseas.