Basic Info.

Model NO.

JD-Q326

Fuel

Electric

Type

Crawler Abrator

Cleanliness

High Cleanliness

Automation

Semi-automatic

Certification

CE

Feature

Shot Blasting/Wheel Blasting by Motor Driving

Condition

New

Customized

Customized

Model

Jd-Q326

Processing Capacity

200kg

Maximum Weight Per Workpiece

15kg

Maximum Load Capacity

200kg

Steel Shot Diameter

0.2-2.5mm

End Disc Diameter

650mm

Track Aperture

10mm

Track Power

1.1kw

Track Speed

3.5r/Min

Sand Blasting Rate

78m/S

Shot Blasting Quantity

110kg/Min

Impeller Diameter

420mm

Impeller Speed

2700rmp

Impeller Power

24t/H

Lifting Rate of Hoist

1.2m/S

Transport Package

Pallet Package or Ton Bag Package

Specification

3792*2600*4768mm

Trademark

Junda

Origin

China

HS Code

84243000

Production Capacity

30-40 Units Per Month

Product Description

Product name:

Product Description:

Shot blasting machine is an effective method to remove the surface contaminant, clean and roughen a smooth surface before applying a primer or coating. Shot blasting equipment is used in almost every industry that uses metal, including aerospace, automotive, construction, foundry, shipbuilding, rail, and many others. Shot blasting machine is a non-standard machine, all the detailed parameters are tailored according to customer object items detailed conditions and customer requirements. Whether wheel blasting or air blasting, our products can meet your demands.

Contact our engineer for competitive shot blasting machine price.

Technical specifications:

We support to customizep,please send us your workpiece size and weight for accurate quotation.

Product details:

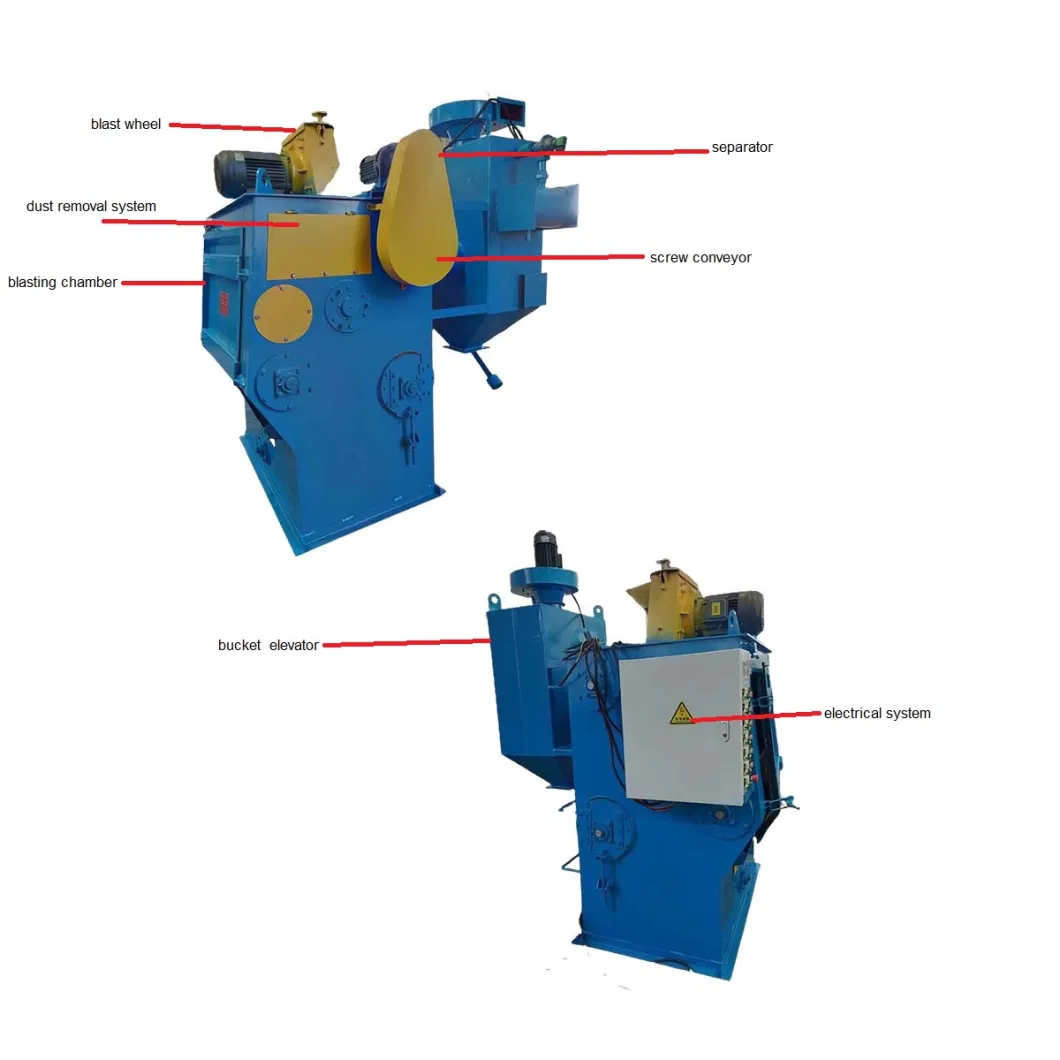

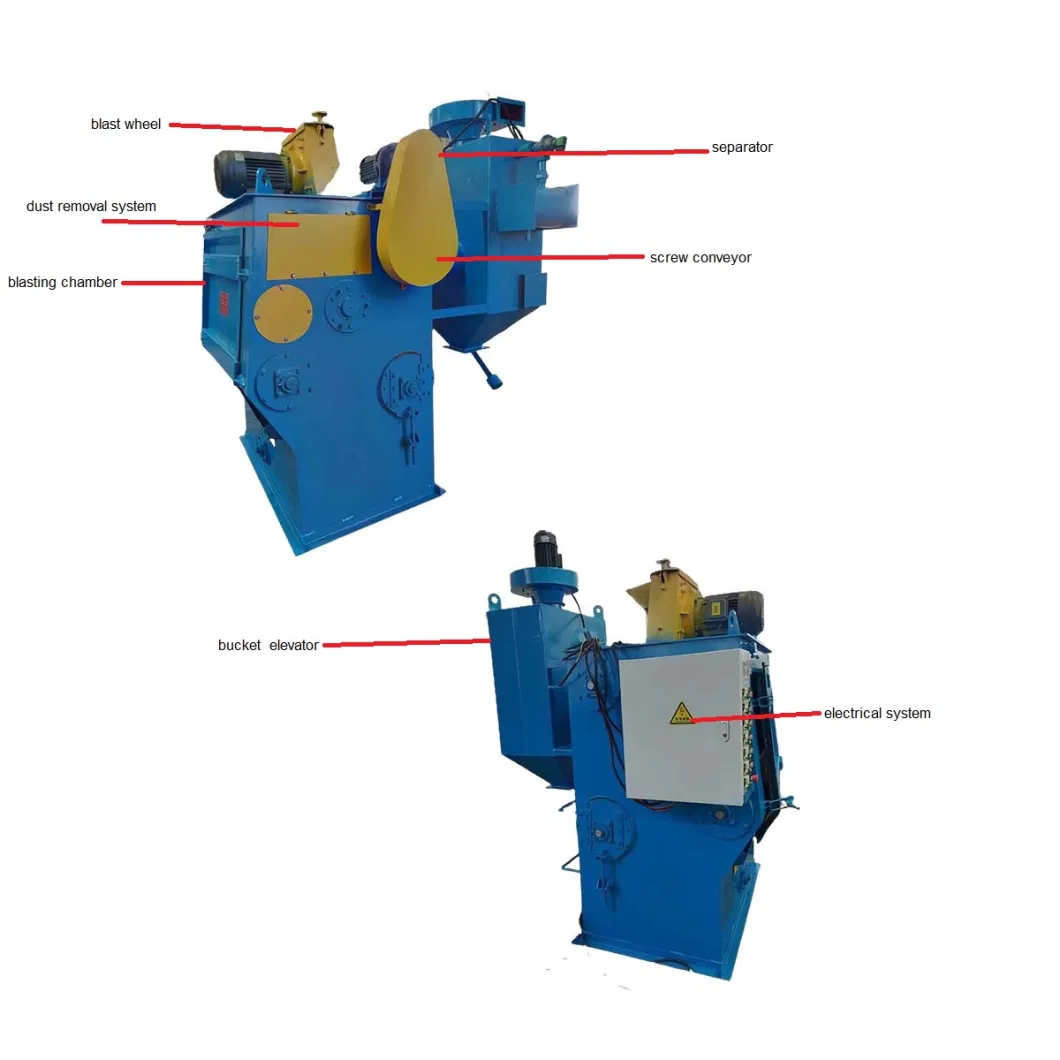

This machine is mainly composed of blasting chamber, blast wheel, bucket elevator, screw conveyor, separator, dust removal system, electrical system, etc.

1,Agriculture industry Shot blasting: Tractor components, water pumps, farm implements, etc.

2,Automobile industry Shot blasting: Engine blocks, cylinder heads, break drums, etc.

3,Building & infrastructure industry Shot blasting: Structural steel, bars, transmission & television towers, etc.

4,Transportation industry Shot blasting: Engine blocks, axle & crank shafts, diesel engine components, etc.

5,Oil & gas industry Surface preparation: Pipes coating with paper, cement, epoxy, polythene, coal tar, etc.

6,Mining industry Shot blasting: Bulldozer, dumpers, crushers, land fill equipments, etc.

7,Foundry industry Shot blasting: Automobile, tractor, scooter & motor cycle components, etc.

8,Aviation industry Shot peening: Jet engine, blades, propeller, turbine, hubs, land gear components, etc.

9,Air polution control equipments Applications: Foundry, carbon black, furnace, cupola, etc.

10,Ceramic/paver industry Applications: Antiskid, footpath, hospital, government buildig, public places, etc.

Packing & Delivery:

Packing & Delivery:

Installation and Warranty:

Installation and Warranty:

1. Installation and commissioning issue:

We will send 1-2 technicians to assist with machine installation and commissioning, customer pays for their tickets, hotel and meals, etc Customer needs arrange 3-4 skilled worker and prepare installation machinery and tools.

2. Warranty time:

12 months from date of commissioning completion, but no more than 18 months from date of delivery.

3. Supply full English documents:

including foundation drawings, operating manual , electric wiring diagram, electric manual book and maintenance book, etc.

Company Profie:

Jinan Junda Industrial Technology is a manufacturer for sandblasting Machinery & Shot Blasting Machine since 2005.

Products cover sandblaster , sandblasting machine , sandblasting cabinet , Dust Collector and full-line Shot Blasting Machines.

We owned 2 work shop area for production .ISO9001 is achieved.

Full set of production ,QC(3 staff) and after-sales (3 staff) guarantee none-defective products.

3D Solidworks is used in designing. R&D staff with over 20 years expertise experience meet your customized requirements.

Our philosophy: Professional, Efficienct, Loyal,

Our mission: To creat core vlaue for our customer,

our staff and our company.

Choose Junda,Get factory price and reliable shot blasting Machinery!

FAQ:

FAQ:

Q1:What is basting speed of tumble belt shot blasting machine ?

A:3-5 min per one batch.

Q2:What is max loading weight of tumble belt shot blasting machine ?

A:200 to 800 kgs.

Q3:What kind of abrasives are used for tumble belt shot blasting machine ?

A:Steel shots, steel grits or steel cut wire.

Q4:Is it necessary to dig pit for installation of tumble belt shot blasting machine ?

A:No

Q5:Is it possible to install tumble belt shot blasting machine by buyer himself ?

A:Yes

Q6:How many operators are needed to run tumble belt shot blasting machine ?

A:1 operator.

Q7:Is the automatic and pneumatic lifting door available ?

A:Optional.

Q8:Is the lift loading bucket available ?

A:Optional.

Q9:How to choose right belt material, rubber or metal?

A:Metal belt normally for hot casting or heavy duty work pieces. Rubber belt normally for normal temperature and common weight work pieces

Inquire now and contact us:

profile beam steel asphalt wire mesh tunnel shot blasting machine

The Crawler rubber belt type shot blasting machine is the smallest compact shot blaster with all in one design,suitable for cleaning the surface of various small and medium parts. easy to packaing and delivery, save space and shipping cost, an ideal surface treatment equipment for modern enterprises.

The Crawler rubber belt type shot blasting machine is the smallest compact shot blaster with all in one design,suitable for cleaning the surface of various small and medium parts. easy to packaing and delivery, save space and shipping cost, an ideal surface treatment equipment for modern enterprises.

Product Description:

Shot blasting machine is an effective method to remove the surface contaminant, clean and roughen a smooth surface before applying a primer or coating. Shot blasting equipment is used in almost every industry that uses metal, including aerospace, automotive, construction, foundry, shipbuilding, rail, and many others. Shot blasting machine is a non-standard machine, all the detailed parameters are tailored according to customer object items detailed conditions and customer requirements. Whether wheel blasting or air blasting, our products can meet your demands.

Contact our engineer for competitive shot blasting machine price.

Technical specifications:

| Junda Crawler Type Shot Blasting Machine | |

| Item | specification |

| Model | JD-Q326 |

| Processing capacity | ≤200KG |

| Maximum weight per workpiece | 15KG |

| Maximum load capacity | 200KG |

| Steel shot diameter | 0.2-2.5mm |

| End disc diameter | 650mm |

| Track aperture | 10mm |

| Track power | 1.1Kw |

| Track speed | 3.5r/min |

| Sand blasting rate | 78m/S |

| Shot blasting quantity | 110KG/min |

| Impeller diameter | 420mm |

| Impeller speed | 2700rmp |

| Impeller power | 7.5Kw |

| Lifting capacity of hoist | 24T/h |

| Lifting rate of hoist | 1.2m/s |

| Hoist power | 1.5Kw |

| Separator separation amount | 24T/h |

| Separator air volume | 1500m³/h |

| Main ventilation volume of precipitator | 2500m³/h |

| Dust collector power | 2.2Kw |

| Dust collector filter material | Filter bag |

| First loading steel shot quantity | 200KG |

| Throughput of bottom screw conveyor | 24T/h |

| Compressed air consumption | 0.1m³/min |

| Gross weight of equipment | 100KG |

| Equipment size length, width and height | 3792×2600×4768 |

| Total power of equipment | 12.6Kw |

Product details:

This machine is mainly composed of blasting chamber, blast wheel, bucket elevator, screw conveyor, separator, dust removal system, electrical system, etc.

Application:

1,Agriculture industry Shot blasting: Tractor components, water pumps, farm implements, etc.

2,Automobile industry Shot blasting: Engine blocks, cylinder heads, break drums, etc.

3,Building & infrastructure industry Shot blasting: Structural steel, bars, transmission & television towers, etc.

4,Transportation industry Shot blasting: Engine blocks, axle & crank shafts, diesel engine components, etc.

5,Oil & gas industry Surface preparation: Pipes coating with paper, cement, epoxy, polythene, coal tar, etc.

6,Mining industry Shot blasting: Bulldozer, dumpers, crushers, land fill equipments, etc.

7,Foundry industry Shot blasting: Automobile, tractor, scooter & motor cycle components, etc.

8,Aviation industry Shot peening: Jet engine, blades, propeller, turbine, hubs, land gear components, etc.

9,Air polution control equipments Applications: Foundry, carbon black, furnace, cupola, etc.

10,Ceramic/paver industry Applications: Antiskid, footpath, hospital, government buildig, public places, etc.

Our Certification:

We owned 2 work shop area for production .ISO9001 is achieved. Full set of production ,QC(3 staff) and after-sales (3 staff) guarantee none-defective products. Packing & Delivery:

Packing & Delivery:  Installation and Warranty:

Installation and Warranty: 1. Installation and commissioning issue:

We will send 1-2 technicians to assist with machine installation and commissioning, customer pays for their tickets, hotel and meals, etc Customer needs arrange 3-4 skilled worker and prepare installation machinery and tools.

2. Warranty time:

12 months from date of commissioning completion, but no more than 18 months from date of delivery.

3. Supply full English documents:

including foundation drawings, operating manual , electric wiring diagram, electric manual book and maintenance book, etc.

Company Profie:

Jinan Junda Industrial Technology is a manufacturer for sandblasting Machinery & Shot Blasting Machine since 2005.

Products cover sandblaster , sandblasting machine , sandblasting cabinet , Dust Collector and full-line Shot Blasting Machines.

We owned 2 work shop area for production .ISO9001 is achieved.

Full set of production ,QC(3 staff) and after-sales (3 staff) guarantee none-defective products.

3D Solidworks is used in designing. R&D staff with over 20 years expertise experience meet your customized requirements.

Our philosophy: Professional, Efficienct, Loyal,

Our mission: To creat core vlaue for our customer,

our staff and our company.

Choose Junda,Get factory price and reliable shot blasting Machinery!

FAQ:

FAQ: Q1:What is basting speed of tumble belt shot blasting machine ?

A:3-5 min per one batch.

Q2:What is max loading weight of tumble belt shot blasting machine ?

A:200 to 800 kgs.

Q3:What kind of abrasives are used for tumble belt shot blasting machine ?

A:Steel shots, steel grits or steel cut wire.

Q4:Is it necessary to dig pit for installation of tumble belt shot blasting machine ?

A:No

Q5:Is it possible to install tumble belt shot blasting machine by buyer himself ?

A:Yes

Q6:How many operators are needed to run tumble belt shot blasting machine ?

A:1 operator.

Q7:Is the automatic and pneumatic lifting door available ?

A:Optional.

Q8:Is the lift loading bucket available ?

A:Optional.

Q9:How to choose right belt material, rubber or metal?

A:Metal belt normally for hot casting or heavy duty work pieces. Rubber belt normally for normal temperature and common weight work pieces

Inquire now and contact us: