- Overview

- Product Description

- Product Parameters

- Finished product display

- Detailed Photos

- Company Profile

- FAQ

Basic Info.

Model NO.

UNS

Rated Power(kVA)

100-1250

Jaw Distance(mm)

55-500

Transport Package

at Customer′s Requrest

Specification

export standard

Trademark

xinchang

Origin

Ningbo China

HS Code

85152900

Production Capacity

200 Sets/ Year

Product Description

Features:

1, Working principle: Take the workpiece to move slowly by controlling system, to clear away by flash the Oxide layer and uneven place of welding surface, then heat the ends of workpiece, the last machine give the upset force very quickly to have the welding ends to fuse.2, Use the micro-controller to achieve complete process control in clamping, flash, upset, holding, stop, very high precision.

3, Welding product's strength is higher, sealing is better, without loose-weld, without gas pore, fastness and beauty.

Applications:

Be widely used for metal products whose ends is not flat and with burr, Tube, bar, sheet metal, section steel which materials are carbon steel, steel alloy and nonferrous metals etc.

Advantages:

1, Machine body of thick steel sheet, not easy to deformation.

2, Fast solenoid valve, making welding speed faster, thereby the productivity is higher, therefore decreasing cost.

3, Cylinder adopt high accurate, anti-friction hard material, which is duralumin, without rust, lower friction, lower noise and loading is faster, thereby reducing the weld spatter.

4, Quality is stable, failure rate is low, therefore machine life is longer.

2, Fast solenoid valve, making welding speed faster, thereby the productivity is higher, therefore decreasing cost.

3, Cylinder adopt high accurate, anti-friction hard material, which is duralumin, without rust, lower friction, lower noise and loading is faster, thereby reducing the weld spatter.

4, Quality is stable, failure rate is low, therefore machine life is longer.

| Model | UNS-100 | UNS-150 | UNS-200 | UNS-250 | UNS-400 | UNS-600 | UNS-800 | UNS-1000 | UNS-1250 | |

| Rated power | KVA | 100 | 150 | 200 | 250 | 400 | 600 | 800 | 1000 | 1250 |

| Min welding area | mm2 | 12.5 | 28 | 28 | 200 | 400 | 400 | 400 | 600 | 600 |

| Max welding area | mm2 | 200 | 314 | 600 | 700 | 1400 | 2200 | 3200 | 4000 | 5500 |

| Jaw distance | mm | 55 | 90 | 90 | 200 | 360 | 360 | 500 | 500 | 500 |

| Adjustable size of Jaw | mm | 30 | 50 | 50 | 150 | 150 | 160 | 200 | 200 | 200 |

| Welding movement speed | mm/s | 5-30 | 5-30 | 5-30 | 5-30 | 5-30 | 5-30 | 5-30 | 5-30 | 5-30 |

| Rated clamping force | KN | 6.1 | 8 | 8 | 300 | 400 | 600 | 600 | 800 | 900 |

| Rated upsetting force | KN | 2.5 | 3 | 3 | 150 | 200 | 300 | 300 | 400 | 450 |

| Welding transformer gears number | 0 | 0 | 0 | 6 | 6 | 6 | 6 | 6 | 6 | |

| Secondary voltage | v | 4-9 | 4-9 | 4-9 | 4-10 | 4-9 | 5-11 | 7.6-14.6 | 7-15 | 7-12.6 |

| cooling water pressure | Mpa | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| Cooling water flow | L/min | 4 | 8 | 12 | 24 | 50 | 60 | 60 | 60 | 60 |

| oil pump motor | kw | 1 | 1.5 | 2 | 4 | 11 | 15 | 22 | 22 | 22 |

| Duty cycle | % | 50 | 50 | 50 | 60 | 60 | 60 | 60 | 60 | 60 |

| Productivity | pc/min | 20 | 20 | 20 | 6 | 6 | 6 | 5 | 5 | 5 |

| Machine weight | kg | 435 | 1350 | 1450 | 5000 | 9000 | 9000 | 15000 | 16000 | 18000 |

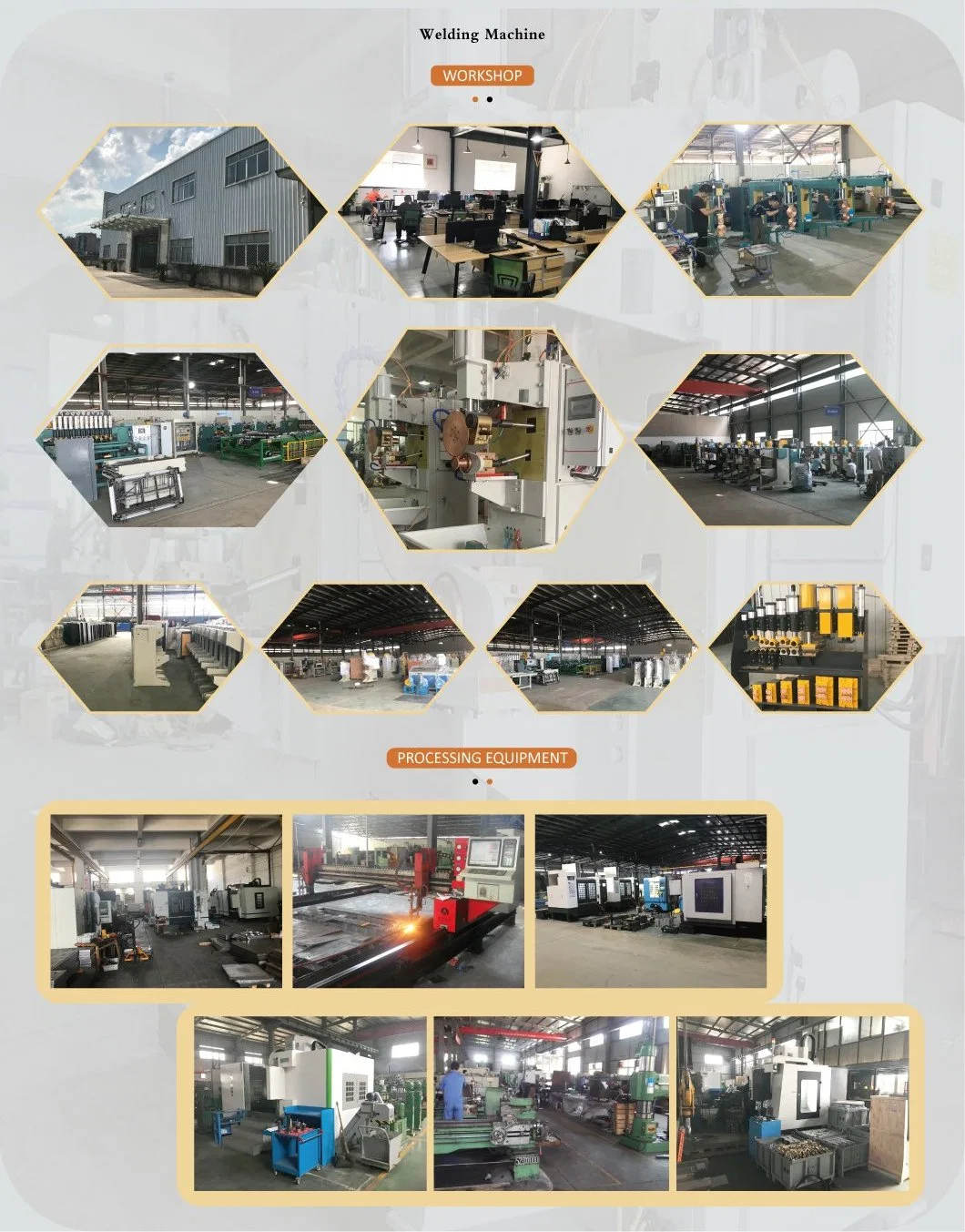

We, Ningbo Xin Chang Machinery Co.,Ltd are a professional designer and manufacturer in friction welding machine, resistance welding machine and Heat exchanger equipment. Our factory is in this line more than 20 years, we have more than 10 senior mechanical and electrical specialists and total more than 200 staff, our machine is famous in China. We have CCC, ISO9001 and CE certificates.

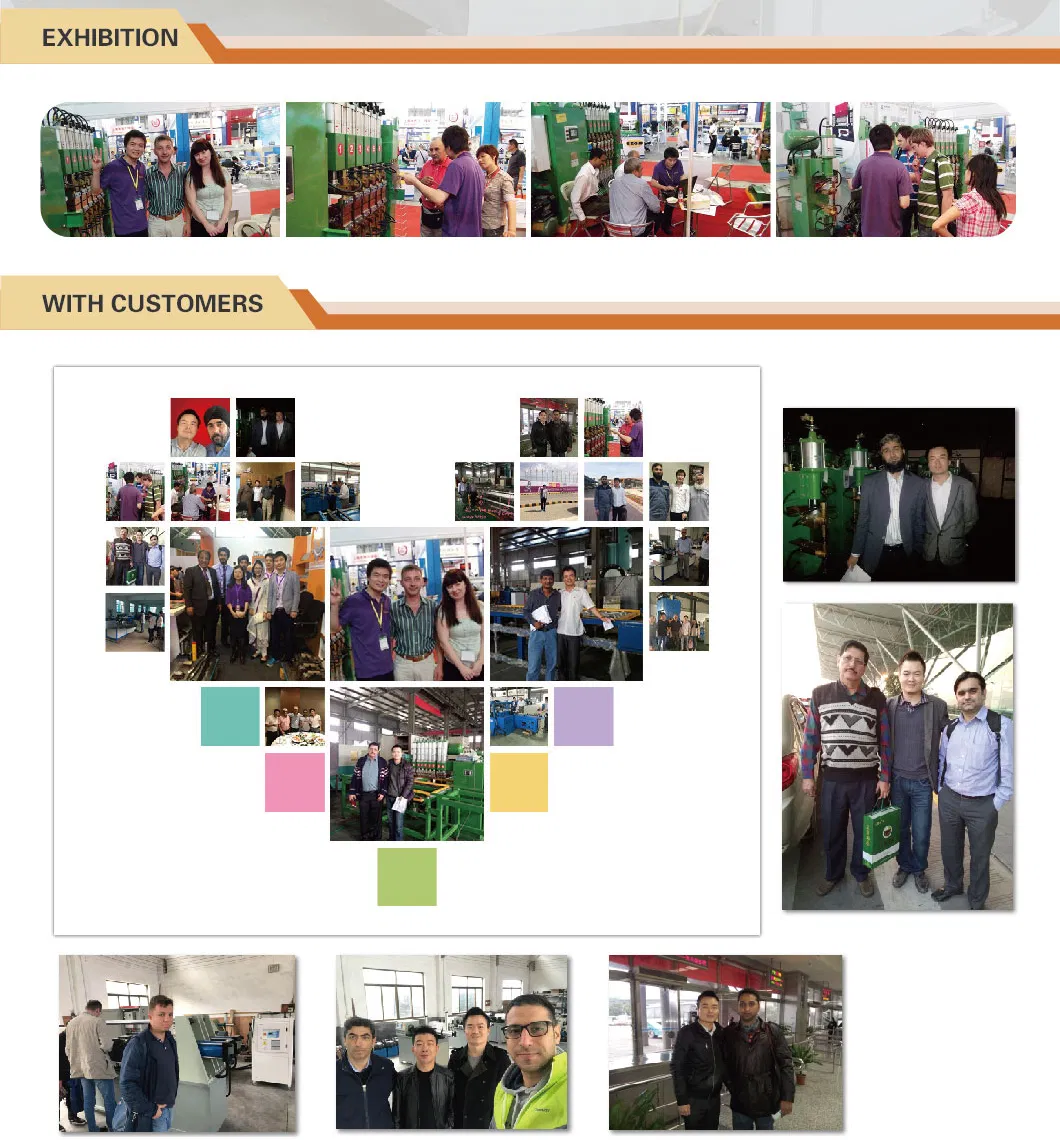

We, Ningbo Xin Chang Machinery Co.,Ltd are a professional designer and manufacturer in friction welding machine, resistance welding machine and Heat exchanger equipment. Our factory is in this line more than 20 years, we have more than 10 senior mechanical and electrical specialists and total more than 200 staff, our machine is famous in China. We have CCC, ISO9001 and CE certificates. Over the years, we have exported so many machines to 30 and more countries, such as France,Spain,Poland,Russia,Indonesia,Vietnam,Pakistan,India,Mexico,Egypt etc.

Our main products are Heat exchanger equipment, Friction welding machine, spot welding machine, projection welding machine, butt welding machine, seam welding machine, multi head welding machine for wire mesh, and other various special welding machine for metal connection in different industries.

We always adhere to the management idea of "Integrity, profession, innovation, and win-win", to make Xin Chang becomes trustworthy enterprise of customers. Good product quality, perfect after-sales service, and professional technical support make customers choose no regrets and worry-free use.

1.Q: What about your standard delivery date ?

1.Q: What about your standard delivery date ? A: Usually 30-60 working days. Our company provide just-in-time delivery

2.Q: How can you guarantee quality?

A: You could test samples before order,and we have professional QC and precise machining equipment; Always final Inspection before shipment;

3.Q: How long is the guarantee?

A: For one year after the custumer received the machine.

4.Q: What do we need to do if the machine fails?

A: In the guarantee time (1 year),we will send the spare parts to you for free,and provide the technical consultant for any time.

5.Q: Can I make my own design and logo on the product?

A: Yes, we do OEM.Welcome global partners.

6.Q: what is the packing mode?

A: wooden case or FCL with container.

7.Q: what is your after-sell service?

A: After-Sales

1) Training your workers how to install the machine, how to use the machine.

2) Engineers available to service machinery overseas

3) 1-year guarantee ( free maintain in a year)

4) Replacement parts and other accessories provided