Basic Info.

Model NO.

SF-100KW

Frequency

20-50kHz

Work Voltage

380V, 400V, 415V, 440V, 480V

The Range of Operating Voltage

340-430V AC

Input Current

150A

Timing (Heat Time,Retain Time,Cool Time)

1-99s

Water Temperature Protection Point

40centidegree

Size

Main Parts:800*600*800mm Transformer: 650*450*600m

Weight

Mainparts:150kg Transformer:105kg

Operation

Automatic and Manial

Transport Package

Plywood Package

Specification

CE, SGS, ISO

Trademark

ORD

Origin

China

HS Code

8514400090

Production Capacity

10, 000sets

Product Description

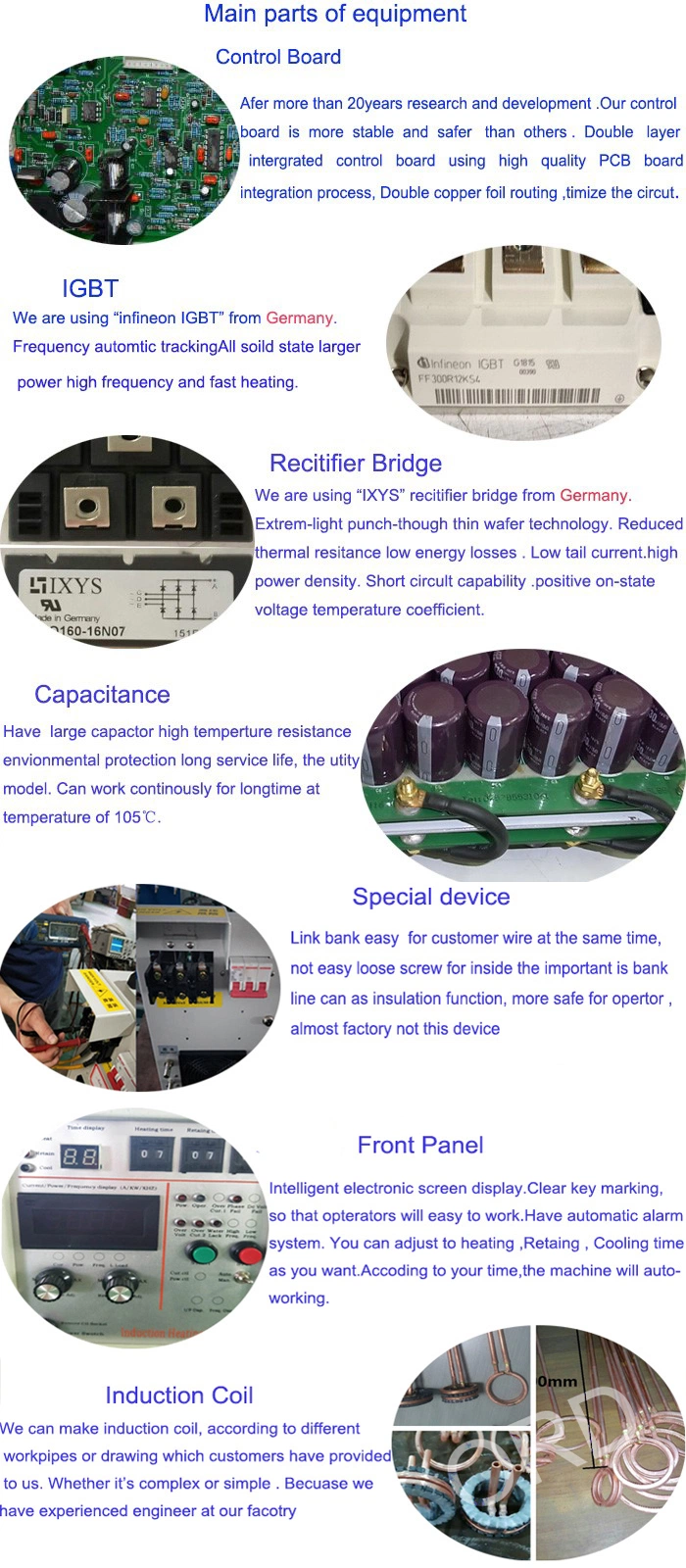

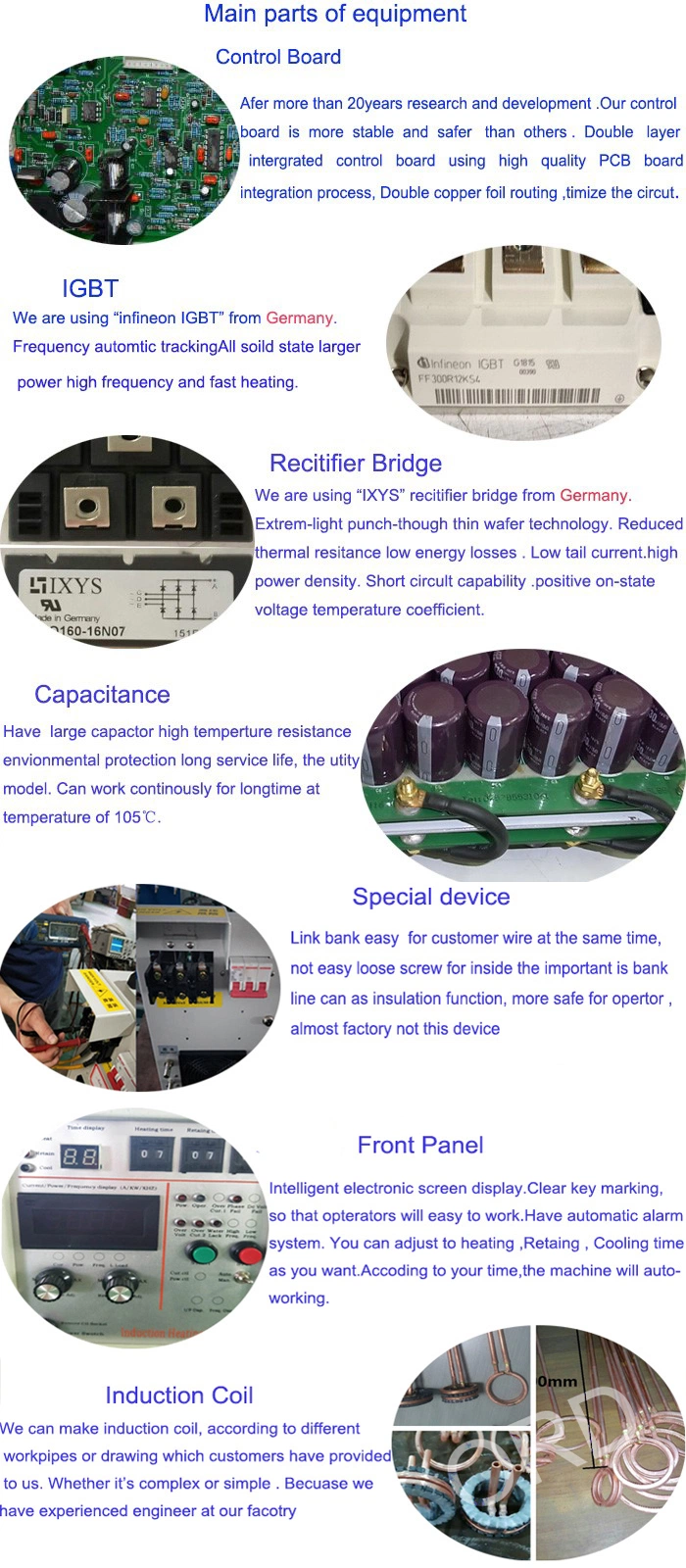

SF-100KW Ultrasonic Induction Heating Equipment

Advantage:

1 More than 21 years experience, stable and goods performance

2 CE certificated

3 Copperated with CHOW TAI FOOKS, Matsushita, Foxconn, Media, Gree and ZHIGAO Air conditioner.

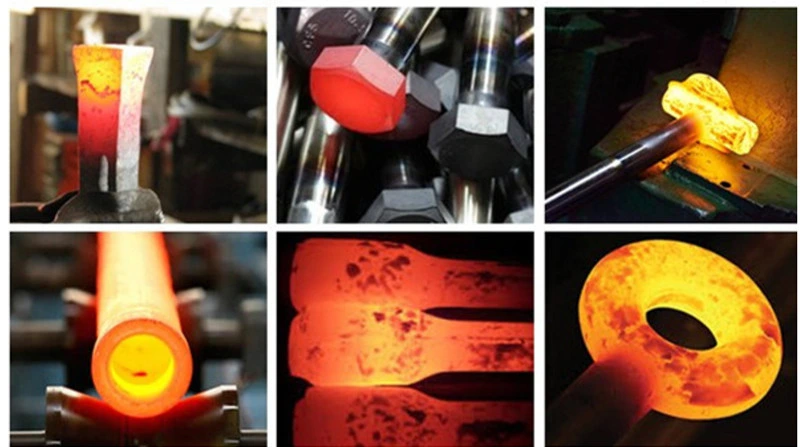

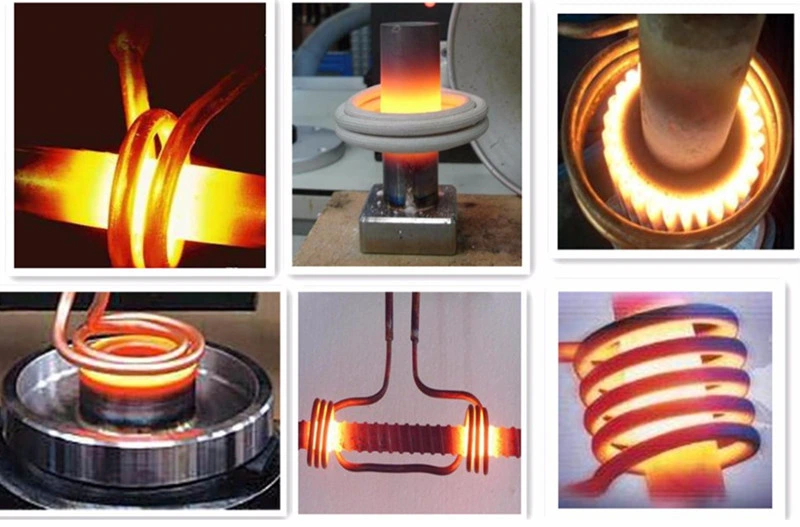

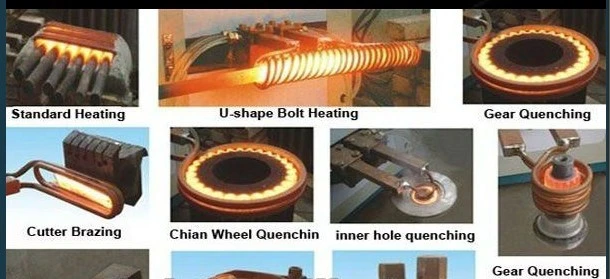

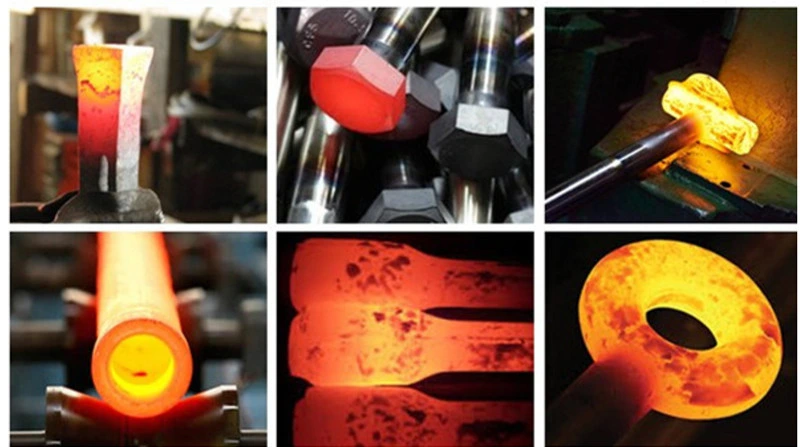

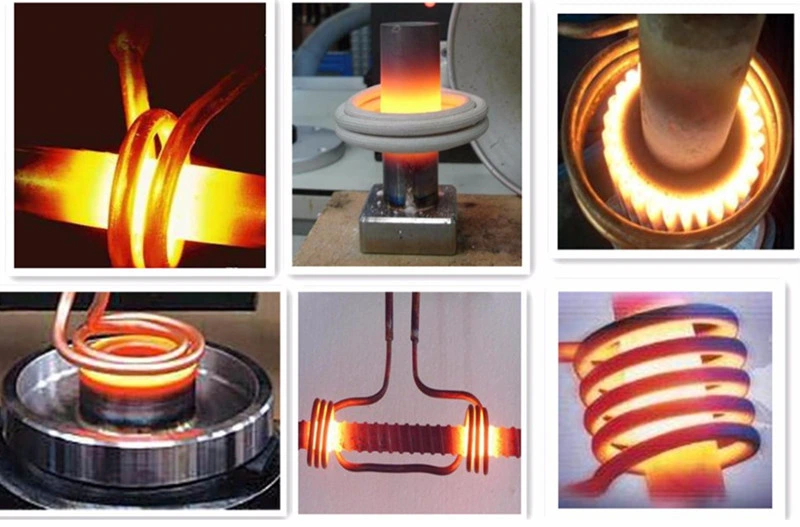

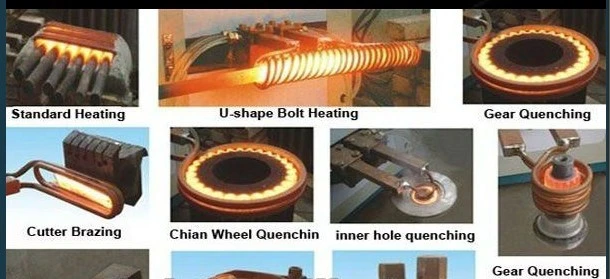

4 Suitable for a large range, heating, quenching, forging, melting, solding and so on.

5 Variable transformer ratios, 8:1,10:1,12:1,14:1,16:1, 8:2,10:2,12:2,14:2,16:2 can match different length induction coil, suitable large range.

Main characteristics:

1 Siemens IGBT module and Inverting technologies of third generation been used; Higher reliability and lower maintenance cost.

2 100% Duty cycle, continuous working is allowed at maximum power output.

3 Display of heating power and heating current and oscillating frequency;

4 Simple to install, Installation can be done by unprofessional person very easily;

5 Light weight

6 Advantages of the model with timer: The power and the operating time of the heating period and the retain period can be preset respectively, to realize a simple heating curve, this model is suggested to use for batch production to improve the repeatability;

Advantage:

1 More than 21 years experience, stable and goods performance

2 CE certificated

3 Copperated with CHOW TAI FOOKS, Matsushita, Foxconn, Media, Gree and ZHIGAO Air conditioner.

4 Suitable for a large range, heating, quenching, forging, melting, solding and so on.

5 Variable transformer ratios, 8:1,10:1,12:1,14:1,16:1, 8:2,10:2,12:2,14:2,16:2 can match different length induction coil, suitable large range.

Main characteristics:

1 Siemens IGBT module and Inverting technologies of third generation been used; Higher reliability and lower maintenance cost.

2 100% Duty cycle, continuous working is allowed at maximum power output.

3 Display of heating power and heating current and oscillating frequency;

4 Simple to install, Installation can be done by unprofessional person very easily;

5 Light weight

6 Advantages of the model with timer: The power and the operating time of the heating period and the retain period can be preset respectively, to realize a simple heating curve, this model is suggested to use for batch production to improve the repeatability;

| Type | SF-100AB |

| Work Power | 3*380v/415v/440v/480v 50-60hz |

| The range of operating voltage | 340-430V AC |

| Output power | 100KW |

| Input current | 150A |

| Fluctuating frequency | 20-50khz |

| Timing (Heat time,Retain time,Cool time) | 1-99S |

| The flow rate of cooling water | 0.15 Mpa 22L/Min |

| Water temperature protection point | 40centidegree |

| Duty cycle | 100% (40degree room temperature) |

| Weight | Mainparts:150Kg Transformer:105kg |

| Size | Main Parts:800*600*800MM Transformer: 650*450*600MM |