- Overview

- Product Parameters

- Product Description

- Detailed Photos

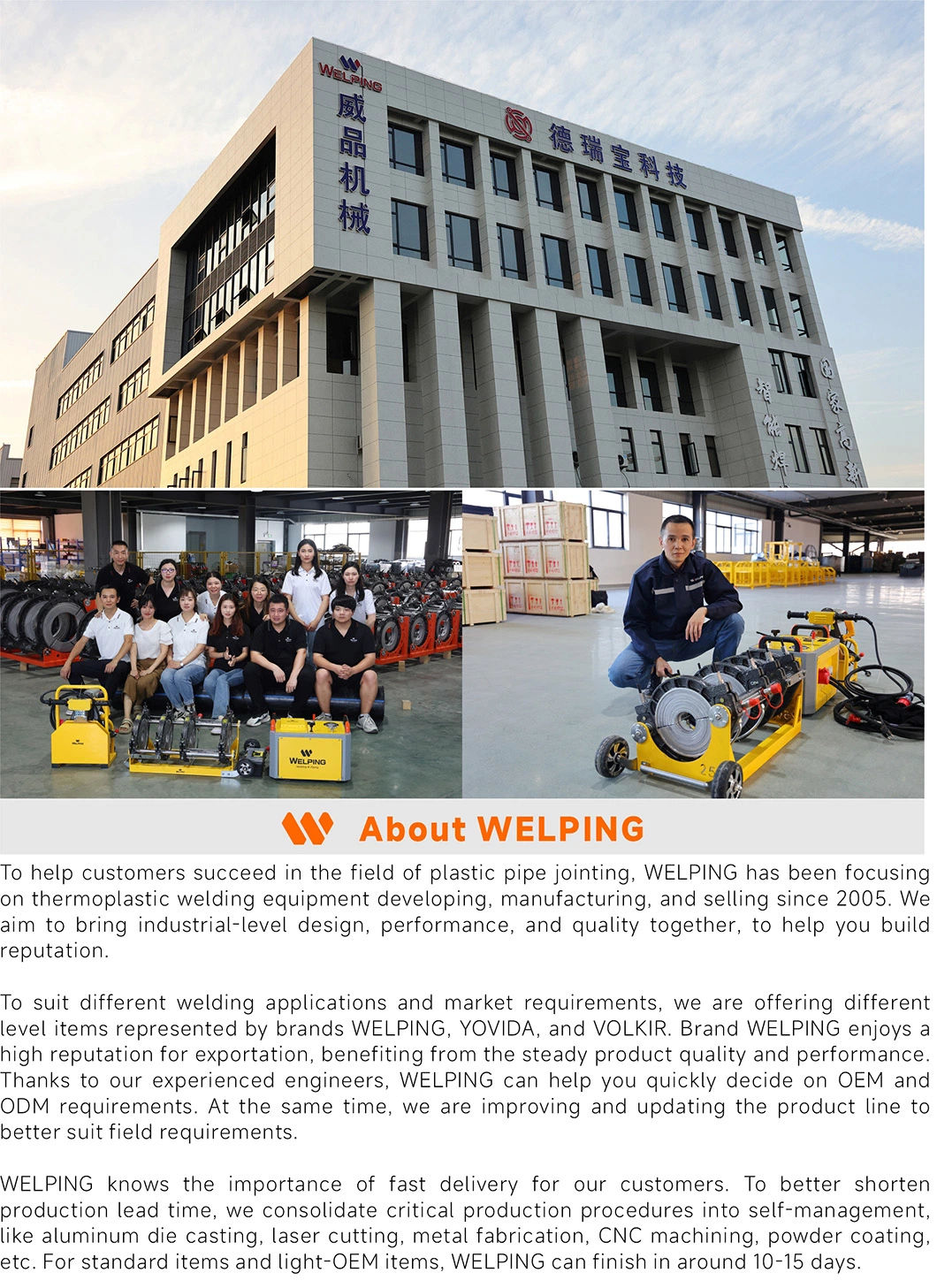

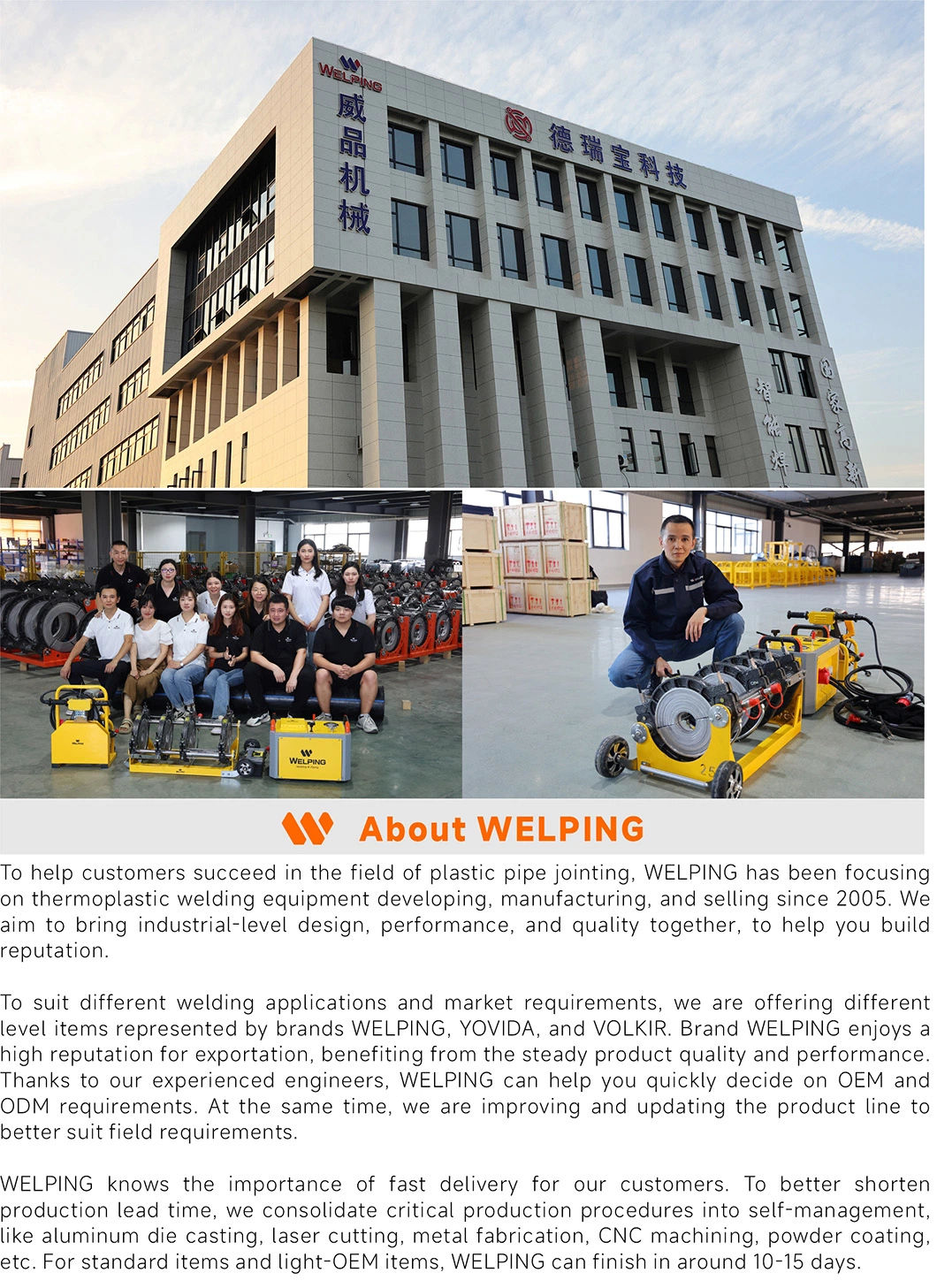

- Company Profile

- Exhibitions

- Applications

- Certifications

- Packaging & Shipping

Basic Info.

Model NO.

WP250A

Frequency Range

Low Frequency

Electric Current

AC

Type

Resistance Butt Welder

Usage

Jointing Plastic Pipes

Welding Method

Hot Melt

After-Sales Service Provided

Spare Parts/Online Support

Applications

Water/Gas Pipelines

Certification

CE/ISO

Color

Customization

Transport Package

Plywood Case

Specification

63-250mm

Trademark

Welping

Origin

Hangzhou, China

HS Code

8515809090

Production Capacity

20000PCS/Year

Packaging & Delivery

Package Size

120.00cm * 80.00cm * 59.00cm

Package Gross Weight

151.000kg

Product Description

The HDPE butt fusion welding machine is a highly efficient and reliable tool used for joining High-Density Polyethylene (HDPE) pipes. It offers several notable features that make it an ideal choice for various applications.

1. Versatility: The machine is designed to fuse HDPE pipes of different sizes, ranging from small to large diameters.

2. User-friendly: The machine is easy to operate, making it suitable for both experienced professionals and beginners. It typically includes clear instructions and intuitive controls, ensuring a hassle-free welding experience.

3. Durability: Made from high-quality materials, the machine is built to withstand harsh working conditions and heavy-duty usage. It is resistant to corrosion, wear, and tear, ensuring long-lasting performance and minimal maintenance requirements.

44. Efficiency: The HDPE butt fusion welding machine offers a fast and efficient fusion process. It typically has a high heating capacity, allowing for quick heating and cooling cycles. This reduces the overall welding time, increasing productivity on the job site.

5. Safety: The machine incorporates various safety features to protect the operator and prevent accidents. These may include automatic temperature and pressure control systems, emergency stop buttons, and safety interlocks.

6. Cost-effective: By providing reliable and durable fusion joints, the machine helps reduce the need for repairs and replacements, resulting in cost savings over time. Additionally, its efficiency and productivity contribute to overall project cost reduction.

1. Versatility: The machine is designed to fuse HDPE pipes of different sizes, ranging from small to large diameters.

2. User-friendly: The machine is easy to operate, making it suitable for both experienced professionals and beginners. It typically includes clear instructions and intuitive controls, ensuring a hassle-free welding experience.

3. Durability: Made from high-quality materials, the machine is built to withstand harsh working conditions and heavy-duty usage. It is resistant to corrosion, wear, and tear, ensuring long-lasting performance and minimal maintenance requirements.

44. Efficiency: The HDPE butt fusion welding machine offers a fast and efficient fusion process. It typically has a high heating capacity, allowing for quick heating and cooling cycles. This reduces the overall welding time, increasing productivity on the job site.

5. Safety: The machine incorporates various safety features to protect the operator and prevent accidents. These may include automatic temperature and pressure control systems, emergency stop buttons, and safety interlocks.

6. Cost-effective: By providing reliable and durable fusion joints, the machine helps reduce the need for repairs and replacements, resulting in cost savings over time. Additionally, its efficiency and productivity contribute to overall project cost reduction.

| Model | WP250A |

| Welding Range | 63-250mm |

| Power Supply | 220V, 50/60Hz, 1PH |

| Overall Power | 5.05kW |

| Heater | 2.3kW |

| Trimmer | 2.0kW |

| Hydraulic Station | 0.75kW |

| Pressure Range | 0-8Mpa |

| Max. Temperature | 270ºC |

| Temperature Deviation | ±5ºC |

| Packing | Plywood Case |

| Package of the frame | 83×56×50cm 70kg |

| Package of the trimmer & Heater & hydraulic station | 77×60×60cm 81kg |

| Total Volume | 0.51cbm |

| Gross Weight | 151kg |