Basic Info.

Model NO.

KYWD800

Automation

Automatic

Certification

CE

Feature

Critical Cleaning / Residue Free

Condition

New

Customized

Customized

Transport Package

Wooden Case/Foam

Specification

60m3

Trademark

Kunyuan

Origin

China

HS Code

84243000

Production Capacity

100 Set

Product Description

Characteristics of this machine:

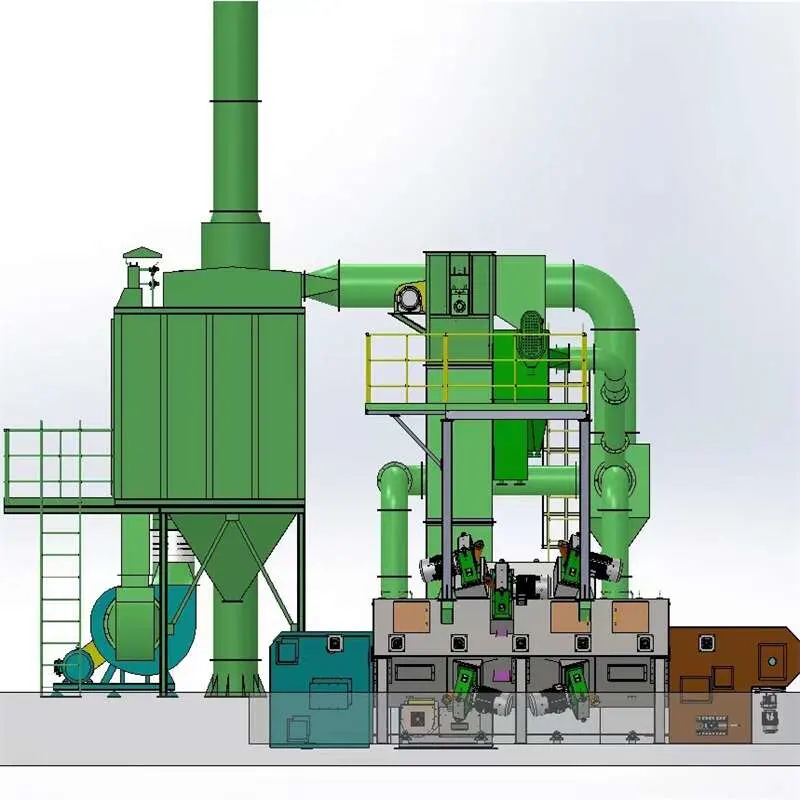

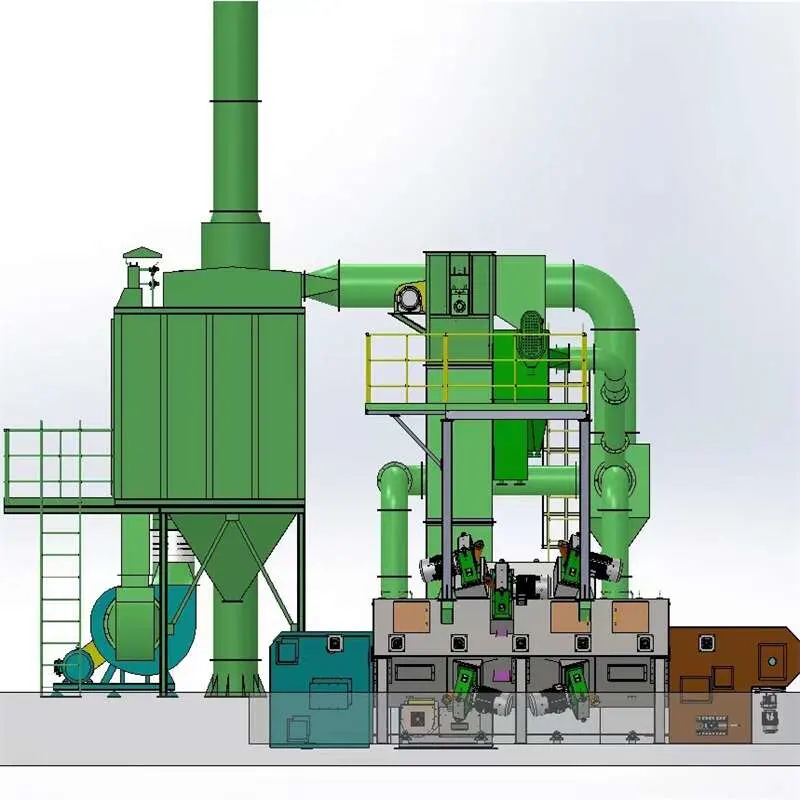

The layout of the shot blasting chamber body and shot blasting device is determined after computer 3D dynamic blasting simulation.

Adopt 4 sets of KYQ035 efficient cantilevered centrifugal blasting devices with a high blasting speed to increase the cleanup efficiency markedly and obtain a satisfactory cleanup quality.

The shot blasting chamber adopts a box structure welded from 10mm-thick steel plates with a high strength and free from vibration. The internal adopts 12mm rolled Mn13, the protective board adopts spigot linkage to extend the service life of the chamber body effectively and can sufficiently take advantage of shot bouncing for secondary cleanup.

The auxiliary front and back sealing chambers adopt a V-shape hinge spring sealing device to prevent shot splash effectively and reduce wearing and scraping to seal by members. The remaining sealing layers adopt high wear-resistant rubber plate seal.

To reduce the friction to the bottom hopper during shot dropping, the hopper contains a

buffer angle.

To prevent work pieces from running away during operation due to misaligned feeding, a

retaining plate is provided at each of both ends of the net belt.

The number of shot blasting devices to be opened can be determined according to work piece size. This can avoid unnecessary energy wasting and at the same time reduce unnecessary damage to equipment.

Our company adopts cast-in big nuts to fix the protective board, which has a structure to allow a larger contact surface with the protective board and prevent more effectively the damage resulting from shots entering the enclosure due to nut loosening.

The shot supply system adopts a special air-controlled shot supply gate valve and photoelectric work piece detection to prevent shots from void blasting. The cylinder gate valve adopted by our company is small, light cylinder without base, ear block. In comparison with a traditional cylinder, it is more stable, reliable and can be maintained more conveniently and quickly.

The dust collection system adopts three-stage impulse filter cartridge dust collector + cyclone body + depositing chamber with a better dust collection effect.

As process equipment is used to convey work pieces, the roller conveyor drive system adopts bidirectional drive.

The lifter anti-reversal adopts a double-safe design: the first is that the drive head wheel adopts a racket and claw mechanism to prevent reversal, the second is that the drive motor adopts a braking motor to prevent reversal. At the same, a lost detection alarm device is provided at the driven wheel.

The roller drive adopts stepless variable frequency speed regulation(siemens) to control the roller running speed range. The whole machine adopts PLC(siemens) to achieve manual, semi-auto and full-auto control. A satisfactory cleanup quality can be obtained.

Full-curtain curtain flow design for separator: The variable pitch separator adopts double-cylinder plus rotary level gauge control to regulate the flow curtain according to the shot condition to achieve a full-curtain curtain flow effect. That technology is unique from our company.

Auto shot replenishing device: In the feed bin on the top of the cleanup chamber, upper and lower level gauges are provided to detect the amount of shots automatically. The lower part of the lifer is equipped with a shot-replenishing hopper and a pneumatic valve to control shot replenishment jointly with the level gauge in the upper feed bin. A level gauge is provided in the shot-replenishing hopper for shot addition alarm.

The dust collection system adopts QL impulse back blow and vertical impulse filter cartridge type dust collector. In comparison with traditional bag type and oblique inserting type filter cartridge, the effect is better. The vertical layout allows filter cartridge replacement to be made more conveniently and quickly(just open the access door), overcoming such disadvantages as being difficult to repair for an oblique inserting type layout and unideal dust collection effect resulting from dust from the filter cartridge on the upper level falling to the filter cartridge on the lower level.

General equipment performance

Main performance parameters

The layout of the shot blasting chamber body and shot blasting device is determined after computer 3D dynamic blasting simulation.

Adopt 4 sets of KYQ035 efficient cantilevered centrifugal blasting devices with a high blasting speed to increase the cleanup efficiency markedly and obtain a satisfactory cleanup quality.

The shot blasting chamber adopts a box structure welded from 10mm-thick steel plates with a high strength and free from vibration. The internal adopts 12mm rolled Mn13, the protective board adopts spigot linkage to extend the service life of the chamber body effectively and can sufficiently take advantage of shot bouncing for secondary cleanup.

The auxiliary front and back sealing chambers adopt a V-shape hinge spring sealing device to prevent shot splash effectively and reduce wearing and scraping to seal by members. The remaining sealing layers adopt high wear-resistant rubber plate seal.

To reduce the friction to the bottom hopper during shot dropping, the hopper contains a

buffer angle.

To prevent work pieces from running away during operation due to misaligned feeding, a

retaining plate is provided at each of both ends of the net belt.

The number of shot blasting devices to be opened can be determined according to work piece size. This can avoid unnecessary energy wasting and at the same time reduce unnecessary damage to equipment.

Our company adopts cast-in big nuts to fix the protective board, which has a structure to allow a larger contact surface with the protective board and prevent more effectively the damage resulting from shots entering the enclosure due to nut loosening.

The shot supply system adopts a special air-controlled shot supply gate valve and photoelectric work piece detection to prevent shots from void blasting. The cylinder gate valve adopted by our company is small, light cylinder without base, ear block. In comparison with a traditional cylinder, it is more stable, reliable and can be maintained more conveniently and quickly.

The dust collection system adopts three-stage impulse filter cartridge dust collector + cyclone body + depositing chamber with a better dust collection effect.

As process equipment is used to convey work pieces, the roller conveyor drive system adopts bidirectional drive.

The lifter anti-reversal adopts a double-safe design: the first is that the drive head wheel adopts a racket and claw mechanism to prevent reversal, the second is that the drive motor adopts a braking motor to prevent reversal. At the same, a lost detection alarm device is provided at the driven wheel.

The roller drive adopts stepless variable frequency speed regulation(siemens) to control the roller running speed range. The whole machine adopts PLC(siemens) to achieve manual, semi-auto and full-auto control. A satisfactory cleanup quality can be obtained.

Full-curtain curtain flow design for separator: The variable pitch separator adopts double-cylinder plus rotary level gauge control to regulate the flow curtain according to the shot condition to achieve a full-curtain curtain flow effect. That technology is unique from our company.

Auto shot replenishing device: In the feed bin on the top of the cleanup chamber, upper and lower level gauges are provided to detect the amount of shots automatically. The lower part of the lifer is equipped with a shot-replenishing hopper and a pneumatic valve to control shot replenishment jointly with the level gauge in the upper feed bin. A level gauge is provided in the shot-replenishing hopper for shot addition alarm.

The dust collection system adopts QL impulse back blow and vertical impulse filter cartridge type dust collector. In comparison with traditional bag type and oblique inserting type filter cartridge, the effect is better. The vertical layout allows filter cartridge replacement to be made more conveniently and quickly(just open the access door), overcoming such disadvantages as being difficult to repair for an oblique inserting type layout and unideal dust collection effect resulting from dust from the filter cartridge on the upper level falling to the filter cartridge on the lower level.

General equipment performance

| S/N | Item | Indicator | |

| 1 | Cleanup chamber opening dimensions (W×H) | 900×400mm | |

| Maximum work piece dimension | Φ800×350mm | ||

| 2 | Net belt load | ≥0.5t/m | |

| 3 | Net belt conveying speed | 0~4m/min (Variable frequency speed regulation) | |

| 4 | Rust removal quality class | GGB8923-88 A-B Sa2.5, Sa2.0 locally | |

| 5 | Abrasive used | 0.4~0.6(stainless steel shots) | |

| 6 | Noise level | ≤90dB, meeting GBJ87-85 standard | |

| 7 | Waste gas emission | ≤80 mg/m3, meeting GBJ4-73 standard | |

| 8 | Nocuous substance content in the workshop workarea | Meeting TJ36-79 standard | |

| 9 | Total air quantity | 15000 m3/h | |

| 10 | Power consu-mption | Total power | Around 95kW(Specific power shall be based on satisfying the use requirements) |

| Total compressed air consumption | 0.6 m3/min | ||

| 11 | Outlne dimensions (excluding the dust collection system) | Length: Around 7,600mm | |

| Width: 3,600mm | |||

| Height: 5,500mm | |||

| Pit: 0mm | |||

| No. | Item | Technical parameter | Remarks | ||

| 1 | Shot blasting cleanup machine | Shot blasting device | Qty. | 4 | |

| Model No. | KYQ035 | ||||

| Shot blasting capacity | 4×250 kg/min | ||||

| Power | 4×15kW | ||||

| Elevator | Elevating capacity | 60 t/h | Polyester belt, casing wear-resitance design, hopper wear-resistance design | ||

| Power | 5.5 kW | ||||

| Longitudinal spiral conveyor | Conveying capacity | 60 t/h | |||

| Power | 5.5 kW | ||||

| Transverse spiral conveyor | Conveying capacity | 50 t/h | |||

| Power | 3 kW | ||||

| Separator | Separating capacity | 60 t/h | |||

| Power | 3kW | ||||

| Shot supply gate | Pneumatic shot supply gate valve | Maximum shot supply capacity 400kg/min | |||

| Shot blasting chamber | Work piece inlet height | 400 mm | Rolled Mn 13 protective boards can be installed in the chamber | ||

| Work piece inlet width | 900 mm | ||||

| Chamber body net belt | Roller diameter × roller distance | Φ20×400mm | The shot blasting chamber is protected using a special type wear-resistant protective sleeve. | ||

| Number of conveying net belts | 1 | ||||

| Net belt load | ≥0.5 t/m | ||||

| Conveying speed | 0~4 m/min | ||||

| 4 | Dust collection system | Air quantity | 15000 m3/h | Shot settling + cyclone dust collection + filter cartridge dust collection | |

| Power | 15kW | ||||

| 5 | power | Around 95kW | |||

| 6 | Electric controll system | The whole set of eqiupment adopts such two modes as PLC automatic variable frequency control and manual control; automatic detection, automatic alarm, automatic disconnection. A safety interlock device is provided between systems. | siemens | ||