Basic Info.

Product Description

Application

Take-up and pay-off machine is mainly used for winding various signal cable, optical cable

Equipment structure

B. Adopt the way of walking beam, the whole cable tray for wiring, implementation of pay-off and take-up.

C. The equipment adopts AC variable frequency motor speed cable, high precision, uniform wiring.

D. PLC programmable controller can be integrated with all kinds of host.

E. Take-up main motor

- Take up main motor adopts DC motor, controller is European series products

- Take up main motor adopts frequency conversion, controller for Siemens products

PN630/1250 Hydraulic swing arm type active pay off machine

Technical parameters:

- Applicable spool: Φ630~1250mm

- Spool width: 475~950mm

- Diameter of top hole: Φ80,125mm

- Applicable conductor diameter: Φ7~40mm

- Pay off motor: 7.5kw Siemens AC variable frequency motor + encoder feedback

- Driver: Siemens inverter

- Pay off speed: 150m/min

- Pay off method: speed/torque pay off

- Lifting motor: hydraulic pump + double oil cylinder.

- Clamping motor: 0.55kw gear motor + screw

- Maximum weight: 2.5t

- Electrical control: Siemens S7-200 + Siemens 7-inch touch screen joint control. The pay off speed is input through the synchronous signal, and the take-up adopts torque take-up. The line pitch is digitally displayed, and the automatic and manual reversing of the cable is corrected for the working position. Line tracking take-up speed.

Technical parameters:

- Applicable spool: Φ630~1250mm

- Spool width: 475~950mm

- Diameter of top hole: Φ80,125mm

- Applicable conductor diameter: Φ7~40mm

- Pay off motor: 7.5kw Siemens AC variable frequency motor + encoder feedback

- Driver: Siemens inverter

- Pay off speed: 150m/min

- Pay off method: speed/torque pay off

- Lifting motor: hydraulic pump + double oil cylinder.

- Clamping motor: 0.55kw gear motor + screw

- Maximum weight: 2.5t

- Electrical control: Siemens S7-200 + Siemens 7-inch touch screen joint control. The pay off speed is input through the synchronous signal, and the take-up adopts torque take-up. The line pitch is digitally displayed, and the automatic and manual reversing of the cable is corrected for the working position. Line tracking take-up speed.

Swing rod structure

Diameter of wire through: Φ6~30mm

| Model | 630/1250 | 800/1600 | 1000/2000 | 1250/2500 |

| Applicable wire-coil specification | PN630-PN1250 | PN800-PN1600 | PN1000-PN2000 | PN1250-PN2500 |

| Applicable cable outer diameter (mm) | ≤25 | ≤40 | ≤50 | ≤60 |

| Applicable wire-coil diameter (mm) | 630-1250 | 800-1600 | 1000-2000 | 1250-2500 |

| Applicable wire-coil width (mm) | 475-950 | 600-1180 | 750-1500 | 950-1900 |

| Take-up speed (mm/min) | ≤100 | ≤100 | ≤80 | ≤60 |

| Winding precision (%) | 1-2 | 1-2 | 1-2 | 1-2 |

| Loading capacity (T) | 2 | 3 | 4.5 | 6 |

Main part brand

2.Frequency converter: Yaskawa

3.Bearing: NSK (Japan brand)

4.Electrical component: Siemens or Omron

5.PLC controller: Siemens

- Inquiry and consulting support

- Customized design support

- View our factory

After-sales service

- Training how to install and how to use the machine

- Engineers available to service machinery overseas

Project show

Take up& pay off in USA plant

Cable extruding machine installation and commissioning site

Malaysia Project

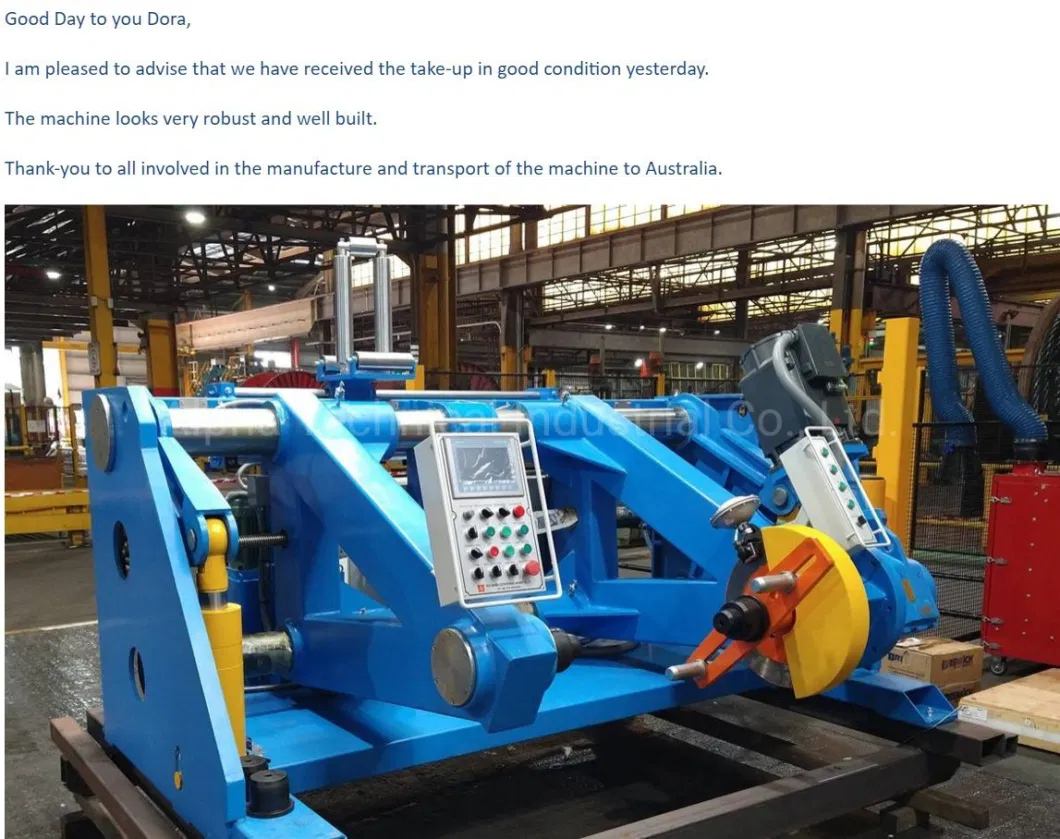

Positive comments from Australia client's mail

Alpha Technical Industrial Co., Ltd is a collection of scientific research and development and production of wire and cable equipment and a variety of efficient energy-saving extrusion production line of key enterprises, so far, the main product including wire and cable Insulation and Sheathing production Line, TQD series Pneumatic Type belt puller, LF series Portal Type Pay-off, LSP series Portal Type Take-up, Various Wire Accumulator, Capstan Haul-off, Pay-off & Take-up, Cooling Water Trough, and Optical Fiber Equipment, Communication Cable Equipment, Signal Cable Equipment.

Our company has a technical administration team who engages wire and cable equipment industrial more than twenty years, as well as experienced engineer and skilled workers, our honest business reputation and good sales achievement, win the trust from our domestic and overseas customers, the products are exported to United States, France, Spain, Portugal, New Zealand, Brazil, Mexico, Chile, South Africa, Zambia, Egypt, South Korea, Singapore, Indonesia, Thailand,etc...

− Q: Are you the manufacturer or trading company?

A: We are the manufacturer. We have a group of highly qualified engineers and experts, who have been working in the field of OFC equipment for more than ten years.

− Q: What is your company's main production?

A: We specialized in optical fiber and optical cable machine researching and manufacturing. Our products include Optical fiber coloring and rewinding machine series, Optical fiber secondary coating line series, Optical cable stranding line, Optical fiber cable sheathing line series and other optical cable equipment.

− Q: What can we offer our customers?

A: Our professional production and technical personnel can train our customers' employees and ensure the smooth production of customers. And will provide our customers with after-sales service.

− Q: How long is the machine warranty?

A: Warranty period of one year (since the completion of mechanical debugging at the buyer's factory)

− Q: Why do I choose your company?

A: We have more than 10 years of professional experience in the production of cable machinery, providing high-quality, high-security products.

We have an experienced team of skilled workers and engineers.

We can support overseas training engineers.

We can customize the design, to accept the customer's sample design.

We can provide customers with after-sales service.

1.Technical drawing of reel, on the drawing we can find reel diameter, center hole diameter and width of reel

2.Pay off and take up speed

3.Loading weight

4.The pay-off and take-up is controlled by torque or speed.